Thermal power generating unit control method and system based on condensate throttling

A technology for condensate water throttling and thermal power units, which is applied in the direction of water supply control, supplementary water supply, preheating, etc., and can solve problems such as low efficiency, reduced service life of equipment, and unit load overload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

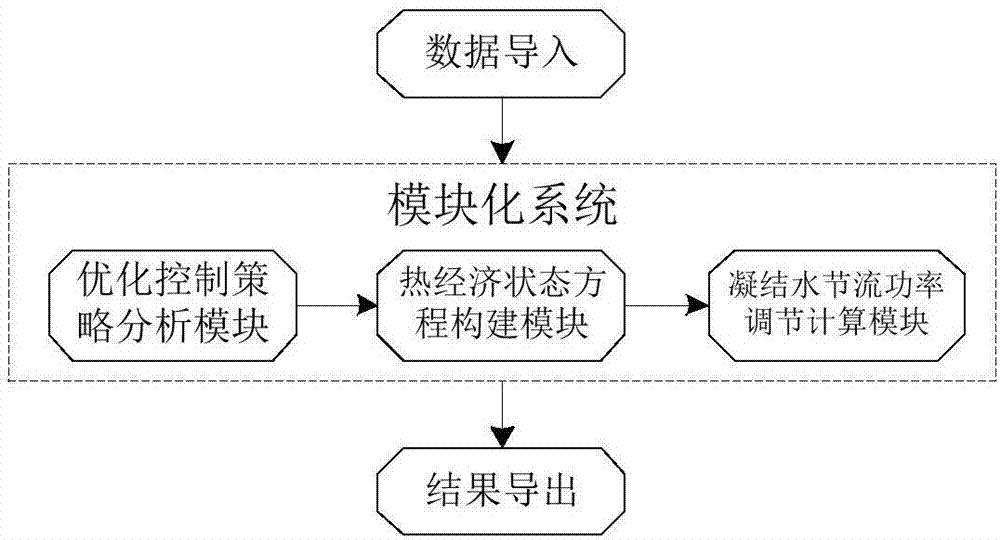

[0064] This embodiment is a thermal power unit control method based on improved condensate throttling, including the following steps:

[0065] Step 1, optimization control strategy analysis

[0066] Step 11 is based on the water level changes of the deaerator and condenser, and adjusts the water level change according to the opening of the water supply regulating valve.

[0067] Step12 Improve the low-pressure heater drainage control system to realize the stable control of the low-pressure heater in the condensate throttling control system and improve the stability of the system.

[0068] Step13 Optimize the control of the load command of the unit to realize the opening and closing of the throttle valve and the control of the caliber flow freely, so as to ensure the safe operation of the unit.

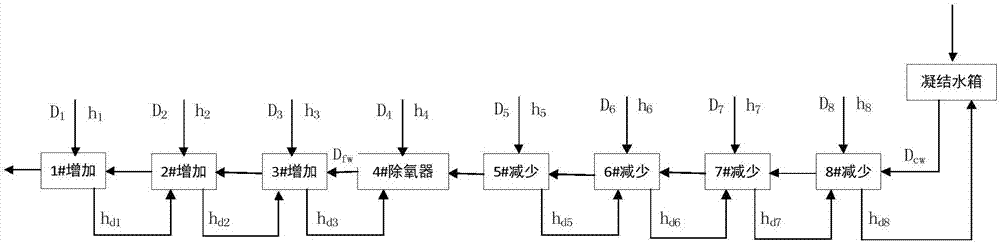

[0069] Step 2, according to the law of conservation of mass and energy, establish the thermal economic state equation

[0070] Step21 soda distribution equation:

[0071] [A][D i ]...

Embodiment 2

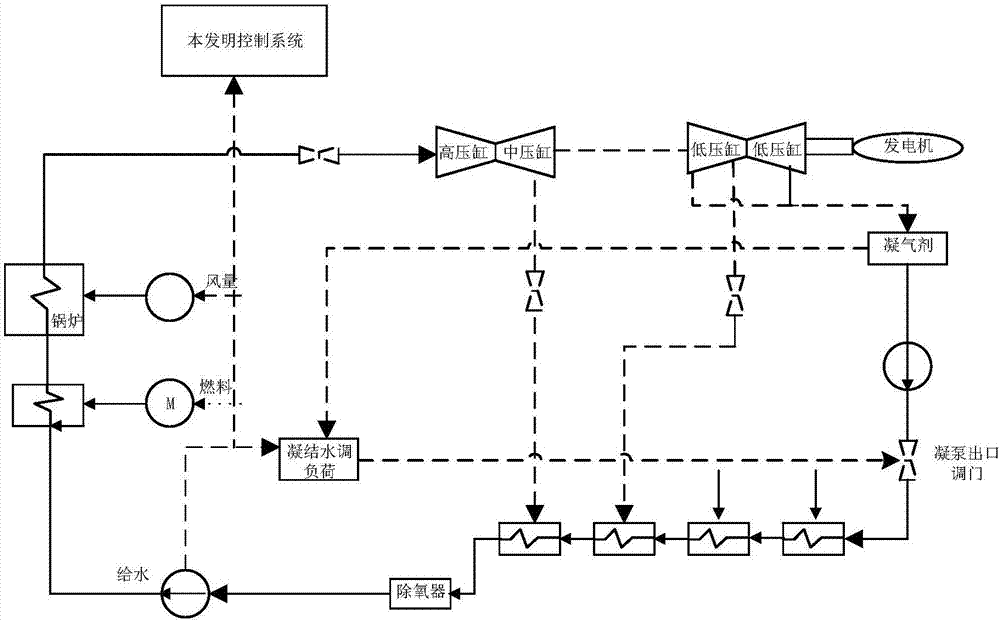

[0108] This embodiment is a thermal power unit control system based on improved condensate throttling, including:

[0109] Optimal control strategy analysis module: Based on the water level changes of the deaerator and condenser, the water level change is adjusted according to the opening of the water supply regulating valve; the low-pressure heater drain control system is improved, and the low-pressure heater is throttled in the condensate The smooth control in the control system improves the stability of the system; optimizes the control of the load command of the unit, realizes the opening and closing of the throttle valve port and the flow control of the caliber freely, and ensures the safe operation of the unit;

[0110] Thermal economic state equation building block: used to construct the steam-water distribution equation, the system power output power equation, and the system power input energy equation;

[0111] Condensate throttling power adjustment calculation module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com