Self-supported and flexible poly(3,4-ethylenedioxythiophene) (PEDOT) nanofiber/single-walled carbon nanotubes (SWCNTs) composite thermoelectric material thin film and preparation method thereof

A technology of nanofibers and material films, which is applied in the direction of thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, nanotechnology, etc., can solve the problems of low performance and inability to use flexible electronic materials, etc., and achieve high yield, The effect of excellent electrical conductivity and good film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

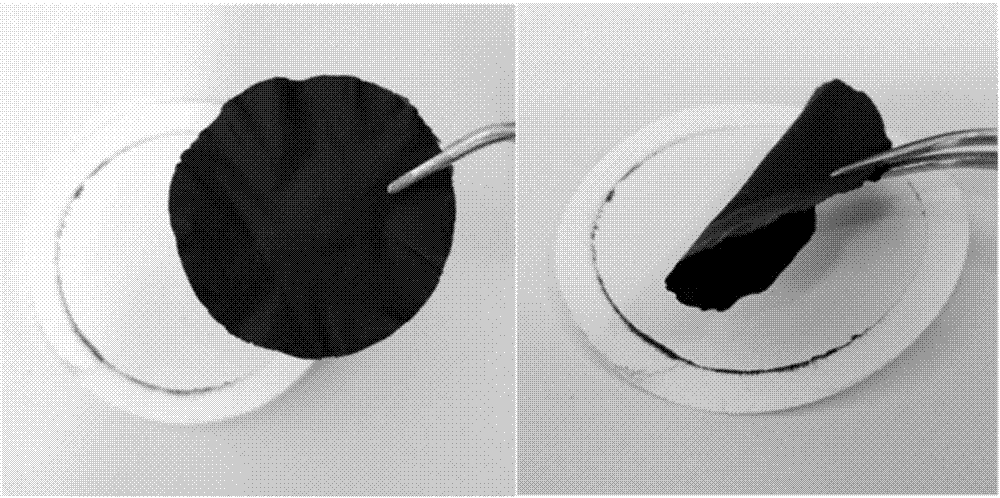

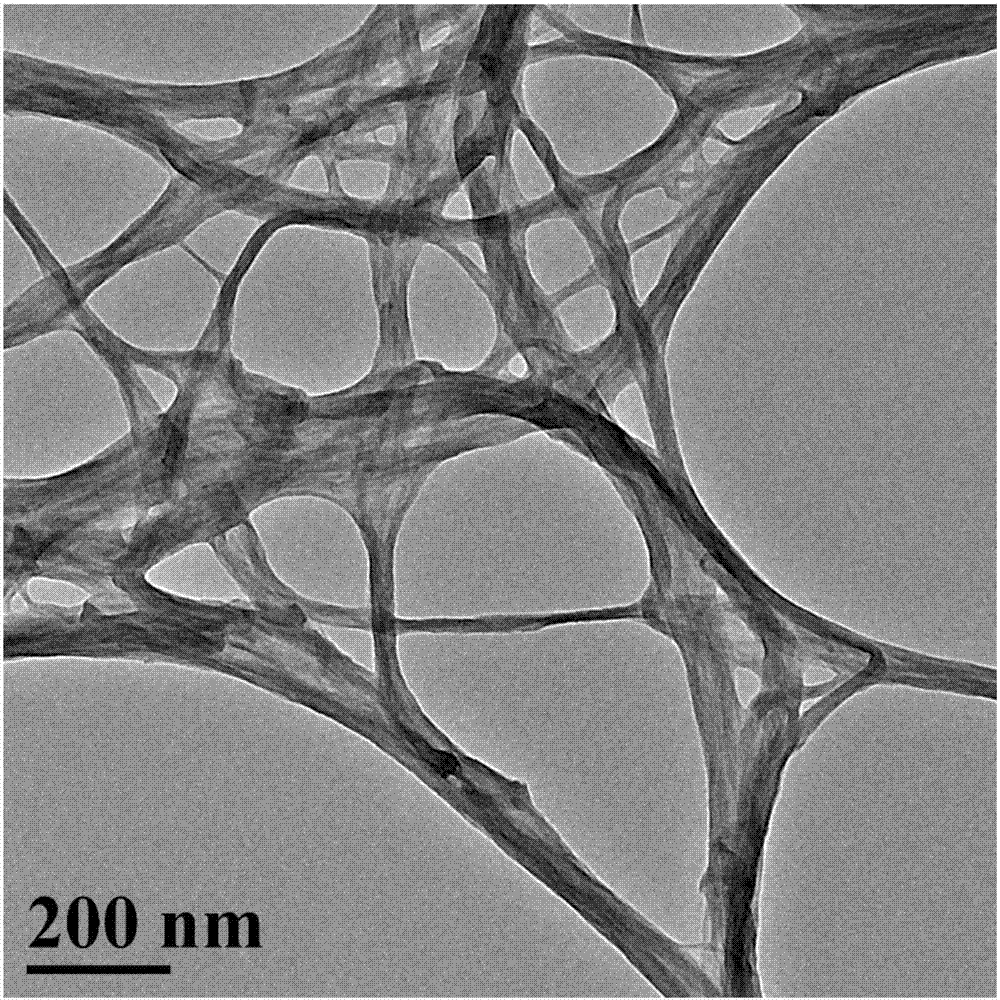

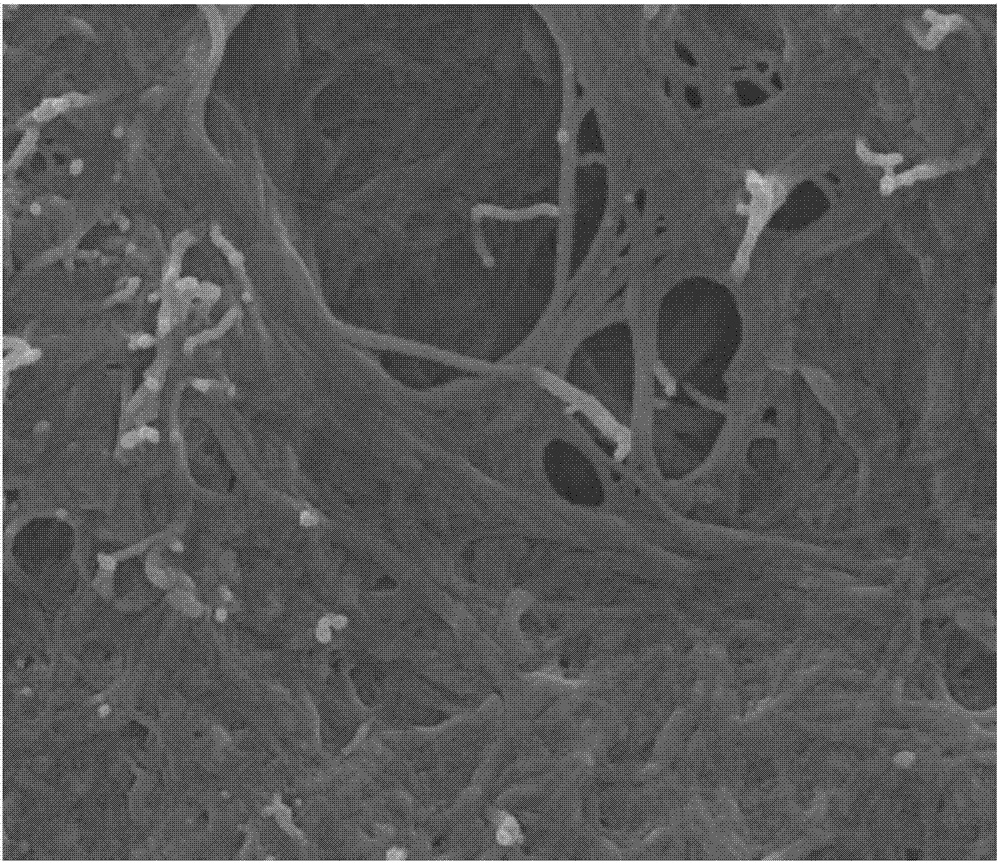

[0041] A self-supporting flexible PEDOT nanofiber / SWCNTs composite thermoelectric thin film material, first with FeCl 3 The methanol dispersion of PEDOT nanofiber was prepared by the self-assembled micelle soft template method as the oxidant, and then it was mixed with the methanol dispersion of SWCNTs by ultrasonic, and the self-assembled film was vacuum-filtered using a microporous filter membrane with a pore size of 0.22 microns, and dried in vacuum After that, the composite membrane falls off from the microporous filter membrane autonomously, and a self-supporting PEDOTnanofiber / SWCNTs thermoelectric thin film is obtained. The surfactant SDS used in the preparation of PEDOT nanofiber, the oxidant FeCl 3 , the molar ratio of the three EDOT monomers is 30:15:7, and the mass fraction of SWCNTs in the composite is 6.7wt%.

[0042] The preparation method of the flexible thin film material with excellent thermoelectric properties is as follows:

[0043] (1) Preparation of PEDO...

Embodiment 2

[0050] A self-supporting flexible PEDOT nanofiber / SWCNTs composite thermoelectric thin film material, first with FeCl 3 The methanol dispersion of PEDOT nanofiber was prepared by the self-assembled micelle soft template method as the oxidant, and then it was mixed with the methanol dispersion of SWCNTs by ultrasonic, and the self-assembled film was vacuum-filtered using a microporous filter membrane with a pore size of 0.22 microns, and dried in vacuum After that, the composite membrane falls off from the microporous filter membrane autonomously, and a self-supporting PEDOTnanofiber / SWCNTs thermoelectric thin film is obtained. The surfactant SDS used in the preparation of PEDOT nanofiber, the oxidant FeCl 3 , the molar ratio of the three EDOT monomers is 30:15:7, and the mass fraction of SWCNTs in the composite is 12.1wt%.

[0051] The preparation method of the flexible thin film material with excellent thermoelectric properties is as follows:

[0052] (1) Preparation of PED...

Embodiment 3

[0056] A self-supporting flexible PEDOT nanofiber / SWCNTs composite thermoelectric thin film material, first with FeCl 3 The methanol dispersion of PEDOT nanofiber was prepared by the self-assembled micelle soft template method as the oxidant, and then it was mixed with the methanol dispersion of SWCNTs by ultrasonic, and the self-assembled film was vacuum-filtered using a microporous filter membrane with a pore size of 0.22 microns, and dried in vacuum After that, the composite membrane falls off from the microporous filter membrane autonomously, and a self-supporting PEDOTnanofiber / SWCNTs thermoelectric thin film is obtained. The surfactant SDS used in the preparation of PEDOT nanofiber, the oxidant FeCl 3 , the molar ratio of the three EDOT monomers is 30:15:7, and the mass fraction of SWCNTs in the composite is 19.2wt%.

[0057] The preparation method of the flexible thin film material with excellent thermoelectric properties is as follows:

[0058] (1) Preparation of PED...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com