Coaly activated carbon and preparation method and application thereof

A technology of coal-based activated carbon and active components, which is applied in the direction of hydrogen halide addition preparation, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of complex preparation process, no special carrier production technology for mercury-free catalyst, and high cost, and achieve The effect of simple process, rich porosity and low ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

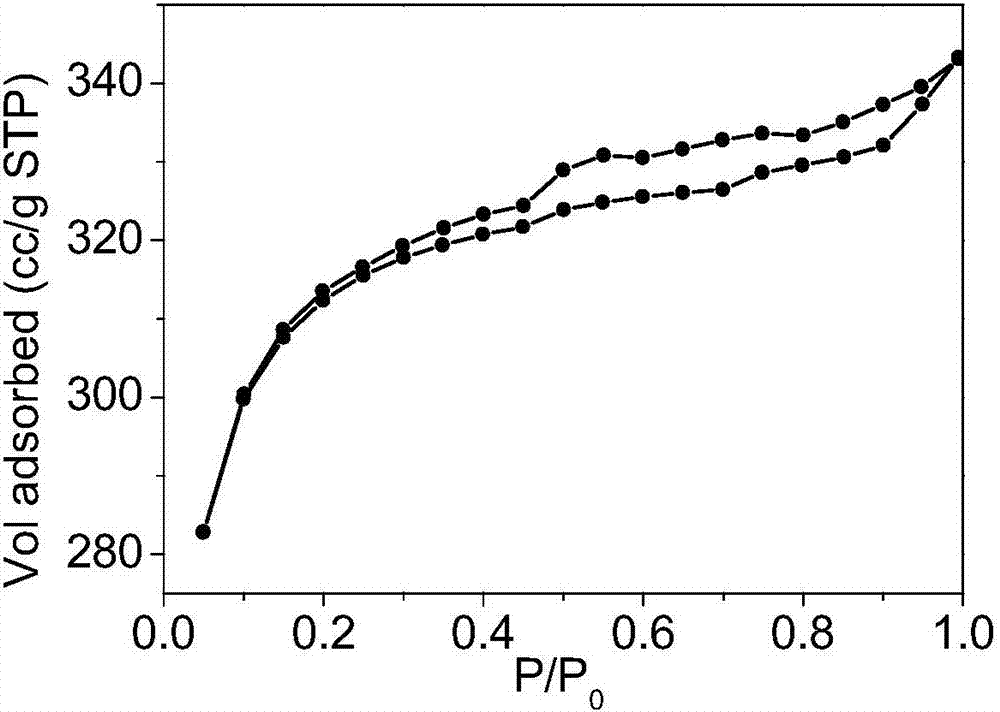

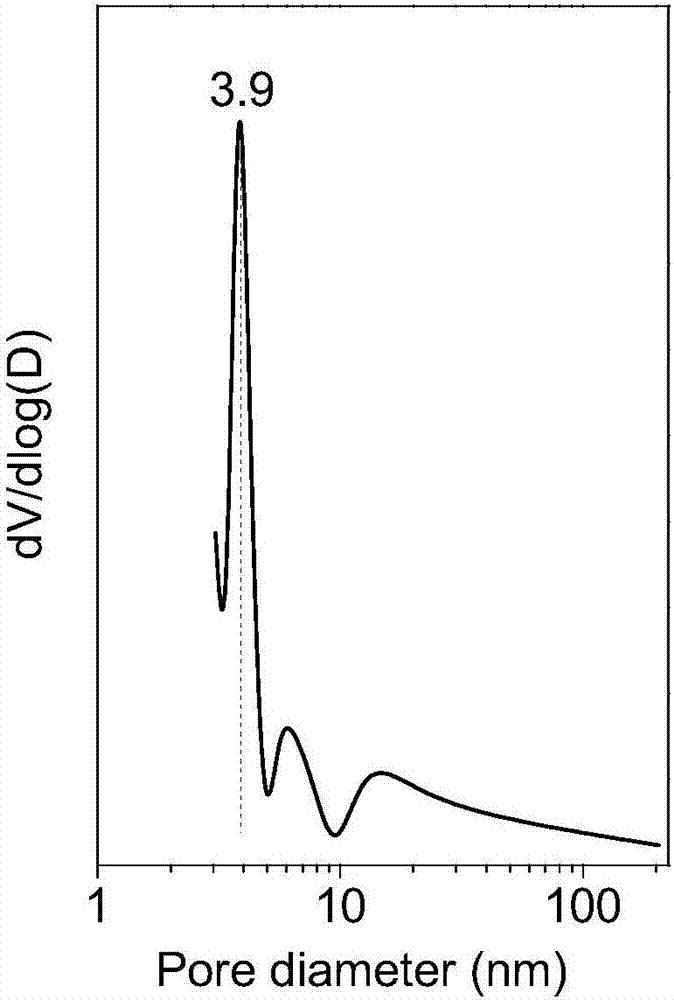

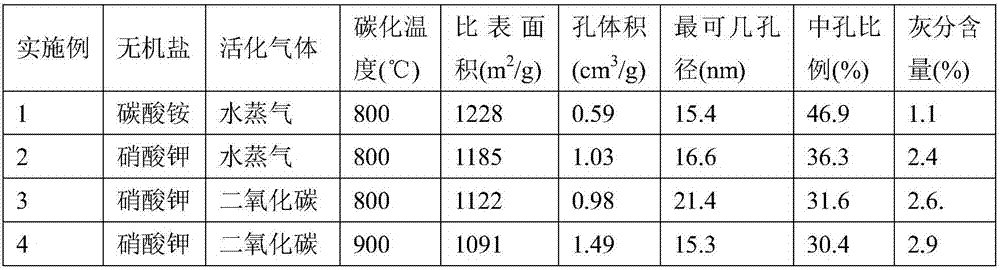

Embodiment 1

[0029]The coal is crushed to 20 mesh to 100 mesh granular coal, and 100 kg of the crushed granular coal and 5 kg of ammonium carbonate are weighed and mixed uniformly to form a reaction raw material. Place the reaction raw materials in the pyrolysis tube, feed nitrogen into the pyrolysis tube and heat the pyrolysis tube so that the temperature of the material in the pyrolysis tube reaches 400°C, and keep the temperature at 400°C for 1 hour. Continue to heat the pyrolysis tube to make the temperature of the material in the pyrolysis tube reach 800°C, then stop feeding nitrogen into the pyrolysis tube, and feed a flow rate of 0.7 kg / h into the pyrolysis tube per kilogram of reaction raw materials Continuously feed water vapor, keep the temperature at 800° C. for 3 hours, and then cool to room temperature under nitrogen atmosphere to obtain 25 kg of coal-based activated carbon.

Embodiment 2

[0031] The coal is crushed to 20 mesh to 100 mesh granular coal, and 100 kg of the crushed granular coal and 2 kg of potassium nitrate are weighed and mixed uniformly to form a reaction raw material. Place the reaction raw materials in the pyrolysis tube, feed nitrogen into the pyrolysis tube and heat the pyrolysis tube so that the temperature of the material in the pyrolysis tube reaches 400°C, and keep the temperature at 400°C for 1 hour. Continue to heat the pyrolysis tube to make the temperature of the material in the pyrolysis tube reach 800°C, then stop feeding nitrogen into the pyrolysis tube, and feed a flow rate of 0.7 kg / h into the pyrolysis tube per kilogram of reaction raw materials Continuously feed water vapor, keep the temperature at 800° C. for 3 hours, and then cool to room temperature under nitrogen atmosphere to obtain 22 kg of coal-based activated carbon.

Embodiment 3

[0033] The coal is crushed to 20 mesh to 100 mesh granular coal, and 100 kg of the crushed granular coal and 5 kg of potassium nitrate are weighed and mixed uniformly to form a reaction raw material. Place the reaction raw materials in the pyrolysis tube, feed nitrogen into the pyrolysis tube and heat the pyrolysis tube so that the temperature of the material in the pyrolysis tube reaches 400°C, and keep the temperature at 400°C for 1 hour. Continue to heat the pyrolysis tube to make the temperature of the material in the pyrolysis tube reach 800°C, then stop feeding nitrogen into the pyrolysis tube, and feed a flow rate of 0.7 kg / h into the pyrolysis tube per kilogram of reaction raw materials Continuously feed carbon dioxide, keep the temperature at 800° C. for 3 hours, and then cool to room temperature under nitrogen atmosphere to obtain 21 kg of coal-based activated carbon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com