Preparation method of polymerizing zirconium tetrachloride type inorganic macromolecular coagulant and application thereof

An inorganic polymer, zirconium tetrachloride technology, applied in chemical instruments and methods, zirconium halide, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of low coagulation effluent, affecting effluent utilization and further treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] First aspect of the present invention is to provide a kind of preparation method of polymerized zirconium tetrachloride inorganic polymer coagulant, described method comprises steps as follows:

[0021] (1) Use deionized water to prepare ZrCl with a concentration of 10%-20% (w / v) (corresponding to a concentration of 111.11-222.22g / L) 4 the solution

[0022] (2) ZrCl 4 Place the solution in an ice-water bath, and slowly add the concentrated alkali solution with a concentration of 80-200g / L to the ZrCl 4 In the solution, continue to stir for 3-5h after the dropwise addition; wherein the concentrated alkali solution and ZrCl 4 The dosage ratio range of the solution is greater than 0-2.5.

[0023] (3) The dripping process of the above-mentioned step (2) is according to the difference of alkalization degree, and the dripping time is controlled within 3h, and then continues to stir for 3-5h, and the solution obtained is all transparent and clear and there is no visible pre...

preparation Embodiment 1

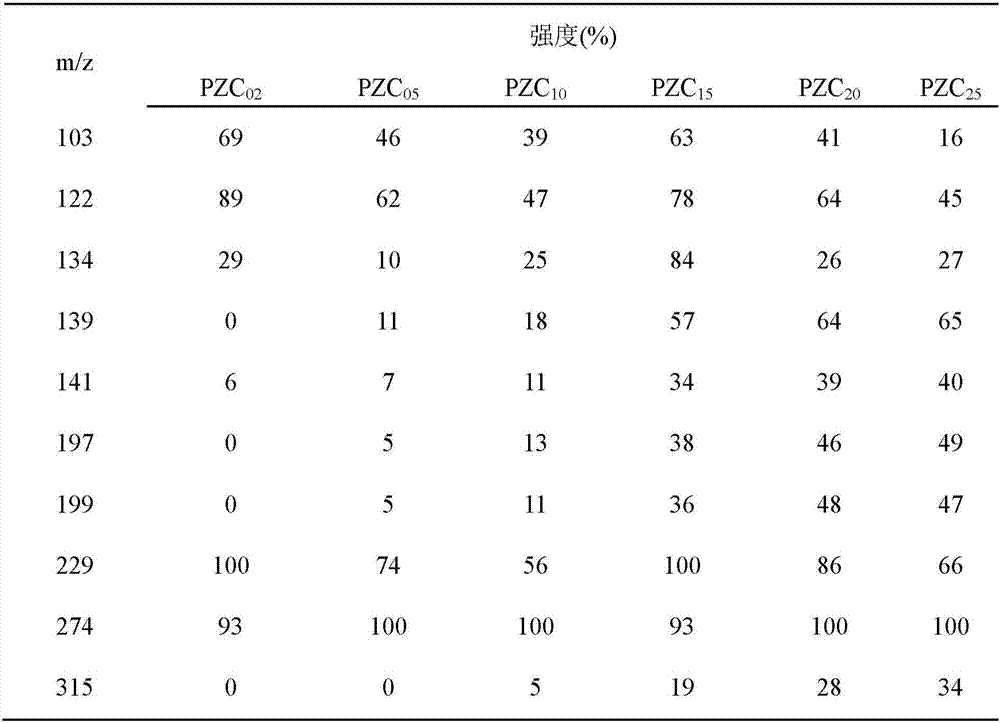

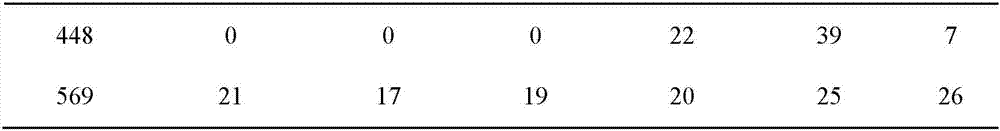

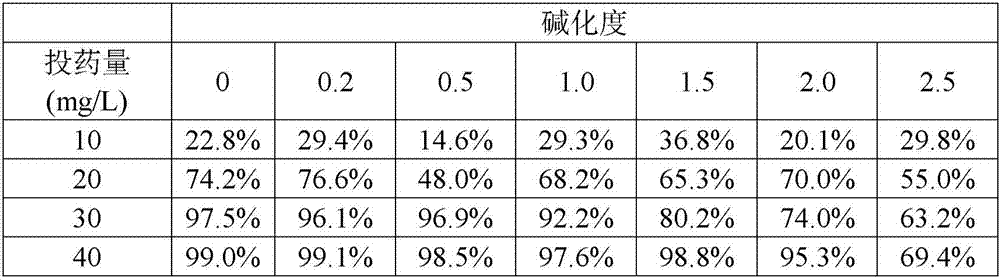

[0045] Weigh ZrCl 4 Powder (Woke, XW100261161) 11.1111g was quickly added to 50mL ice deionized water under the stirring condition of 500rpm, and after it was dissolved, the ZrCl 4 The solution was transferred to a 100mL volumetric flask, and the ice deionized water was constant to obtain 10wt% ZrCl 4 solution; after that, measure 10wt% of ZrCl 4 Solution 10mL, in the case of vigorous stirring, add 100g / L NaOH solution dropwise through a basic burette, and the dropping volume is 0.3812mL, 0.953mL, 1.906mL, 2.859mL, 3.812mL, 4.765mL, 5.718mL . The dropping times were 10, 20, 40, 80, 120, and 150 minutes, respectively. Continue to stir for 3-5h after the dropwise addition, to obtain the polymerized zirconium tetrachloride inorganic polymer coagulant whose alkalization degree (expressed by B) is 0.2, 0.5, 1.0, 1.5, 2.0, 2.5 respectively, and the prepared product is listed as N1 , N2, N3, N4, N5, N6 said. Electrospray ionization ion-of-flight mass spectrometry (ESI-TOF-MS) wa...

preparation Embodiment 2

[0051] Weigh ZrCl 4 Powder (Wokai, XW100261161) 5.5556g, under the stirring condition of 500rpm, quickly add into 25mL ice deionized water, after it dissolves, ZrCl 4 The solution was transferred to a 50mL volumetric flask, and the ice deionized water was constant to obtain 10wt% ZrCl 4 solution; after that, measure 10wt% of ZrCl 4 Solution 5mL, in the case of vigorous stirring, dropwise add 100g / L KOH solution through the alkaline burette, the drop volume is 0.2669mL, 0.667mL, 1.334mL, 2.002mL, 2.669mL, 3.336mL, 4.003mL . The dropping times were 10, 20, 40, 80, 120, and 150 minutes, respectively. Continue to stir for 3-5h after the dropwise addition, to obtain the polymerized zirconium tetrachloride inorganic polymer coagulant whose alkalization degree (expressed by B) is 0.2, 0.5, 1.0, 1.5, 2.0, 2.5 respectively, and the prepared product is listed as N1 , N2, N3, N4, N5, N6 said.

[0052] The inorganic macromolecular polymerization coagulant provided by the invention ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com