Humic acid bagging-free film bag and preparing method and use method thereof

A humic acid and film covering technology is applied in the field of agricultural applications, which can solve the problems of single function of film-free bags, easy storage period of sunburned apples, no antibacterial ability, etc., so as to prevent bacterial infection and pest damage to apples. Effect of growth, bright color, effect of preventing the entry of air and bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

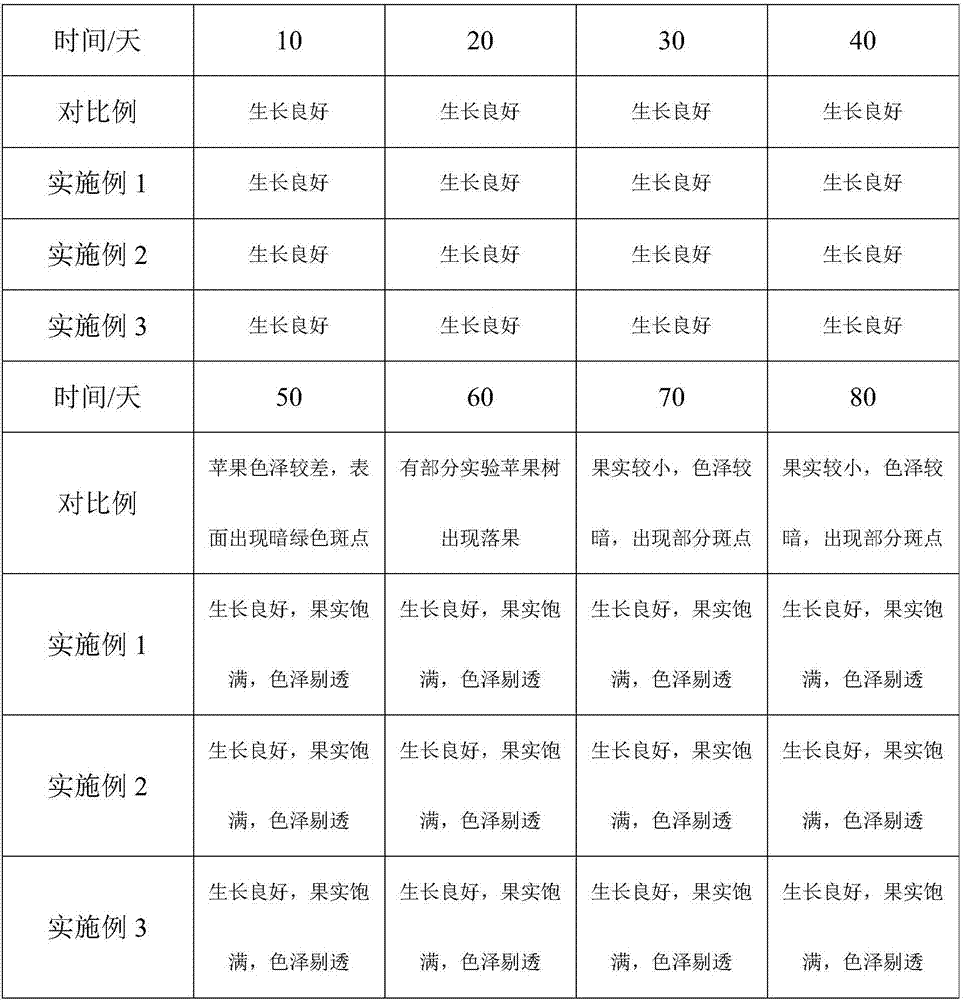

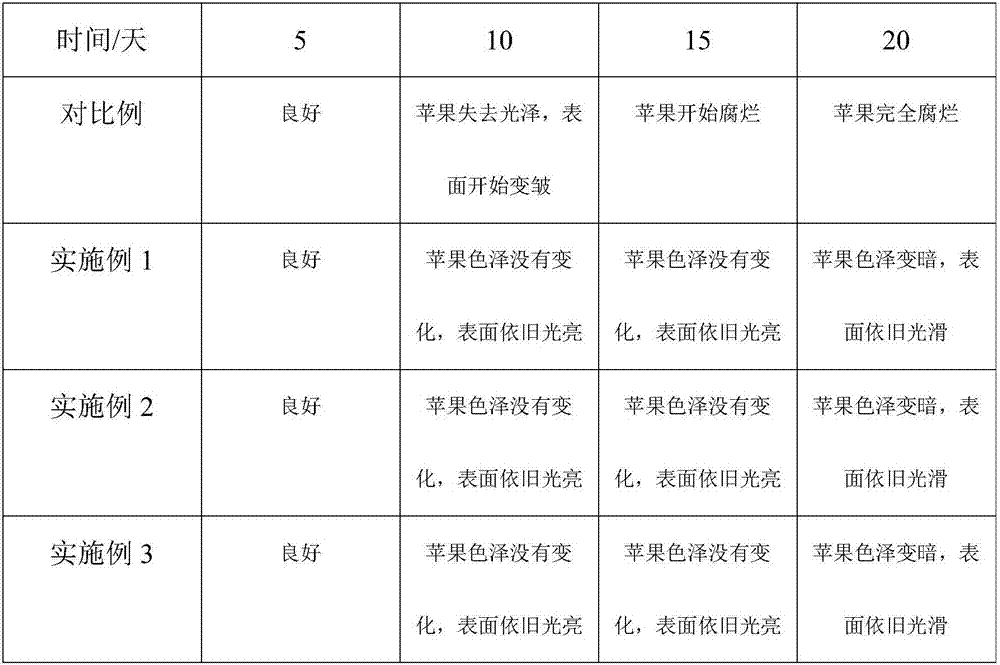

Examples

Embodiment 1

[0024] Prepare a new type of multifunctional humic acid-free film bag, which is prepared from the following components by mass: humic acid 10kg, potassium hydroxide 10kg, chitosan 15kg, nano-SiO 2 1.1kg, glycerin 0.6kg, fenugreek gum 1.0kg, water 30kg.

[0025] The above raw materials are all commercially available products, and there is no restriction on the manufacturer.

[0026] Preparation method: First, 0.6kg of nano-SiO 2 , dissolve in 0.2% acetic acid aqueous solution, stir evenly, add 15kg chitosan, add 0.6kg glycerin after fully dissolving, stir evenly, obtain chitosan composite mother liquor.

[0027] Then get 10kg of humic acid and dissolve it in potassium hydroxide solution to make potassium humate solution, and dissolve 1.0kg of fenugreek gum in it; Potassium humate solution of glue, and then add the remaining glycerin under the action of stirring until a stable and uniform system is formed, that is, the mother liquor of humic acid free film bag is obtained.

Embodiment 2

[0029] Prepare a new type of multifunctional humic acid-free film bag, which is prepared by weight from the following components: humic acid 15kg, potassium hydroxide 15kg, chitosan 20kg, nano-SiO 2 0.8kg, glycerin 2.3kg, fenugreek gum 1.5kg, water 30kg.

[0030] The above raw materials are all commercially available products, and there is no restriction on the manufacturer.

[0031] Preparation method: First, 0.8kg of nano-SiO 2 , dissolve in 0.8% acetic acid aqueous solution, stir evenly, add 20kg chitosan, add 0.8kg glycerin after fully dissolving, stir evenly, obtain chitosan composite mother liquor. Then get 15kg of humic acid and dissolve it in potassium hydroxide solution to make potassium humate solution, and dissolve 1.5kg of fenugreek gum in it; Potassium humate solution of glue, and then add the remaining glycerin under the action of stirring until a stable and uniform system is formed, that is, the mother liquor of humic acid free film bag is obtained.

Embodiment 3

[0033] Prepare a new type of multifunctional humic acid-free film bag, which is prepared by weight from the following components: humic acid 20kg, potassium hydroxide 20kg, chitosan 25kg, nano-SiO 2 1.0kg, glycerin 4.0kg, fenugreek gum 2kg, water 30kg.

[0034] The above raw materials are all commercially available products, and there is no restriction on the manufacturer.

[0035] Preparation method: First, 1.0kg of nano-SiO 2 , dissolved in 1.5% acetic acid aqueous solution, stirred evenly, added 25kg chitosan, fully dissolved, added 1.0kg glycerin, stirred evenly, and prepared chitosan composite mother liquor. Then get 20kg of humic acid and dissolve it in potassium hydroxide solution to make potassium humate solution, and dissolve 2.0kg of fenugreek gum in it; Potassium humate solution of glue, and then add the remaining glycerin under the action of stirring until a stable and uniform system is formed, that is, the mother liquor of humic acid free film bag is obtained. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of acetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com