In-situ co-assembly synthesis adsorption-photocatalytic composite material based on UIO-66 and copper nanowires

A UIO-66, copper nanowire technology, applied in the field of composite materials, can solve the problems of no obvious improvement in hydrogen production activity, small pore size, insufficient adsorption strength, etc., to promote photoelectric separation efficiency and visible light absorption, strong adsorption capacity , the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

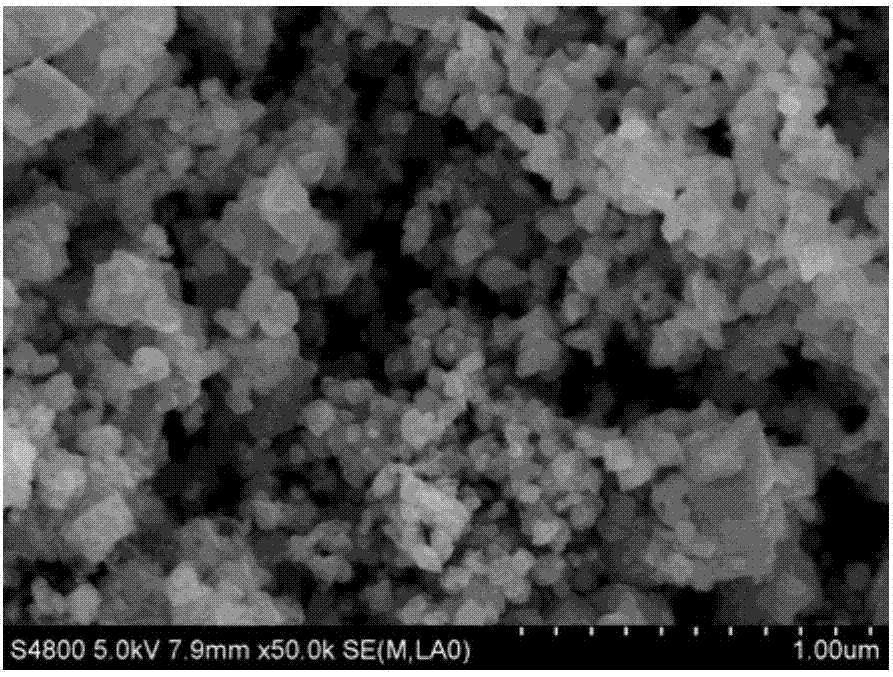

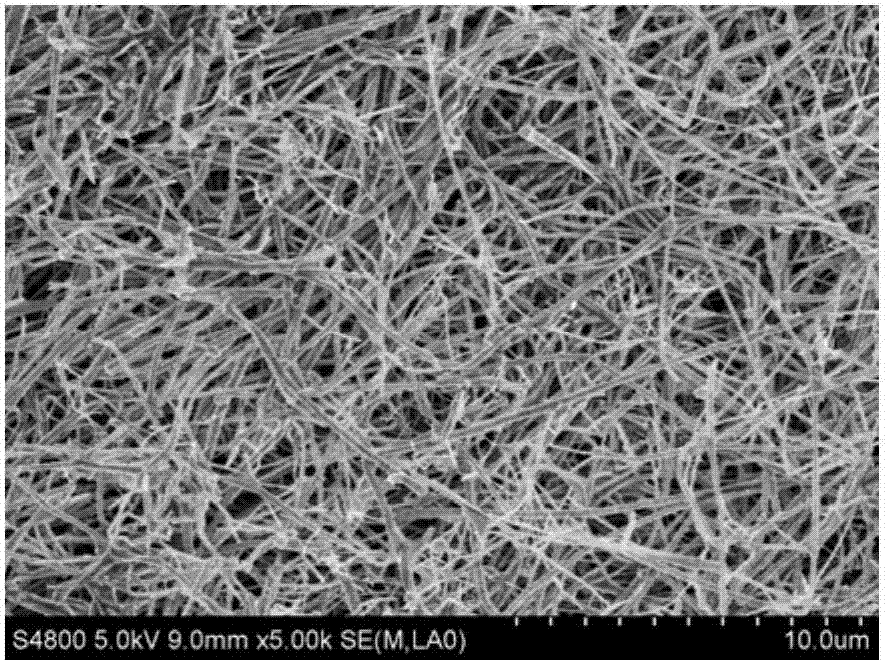

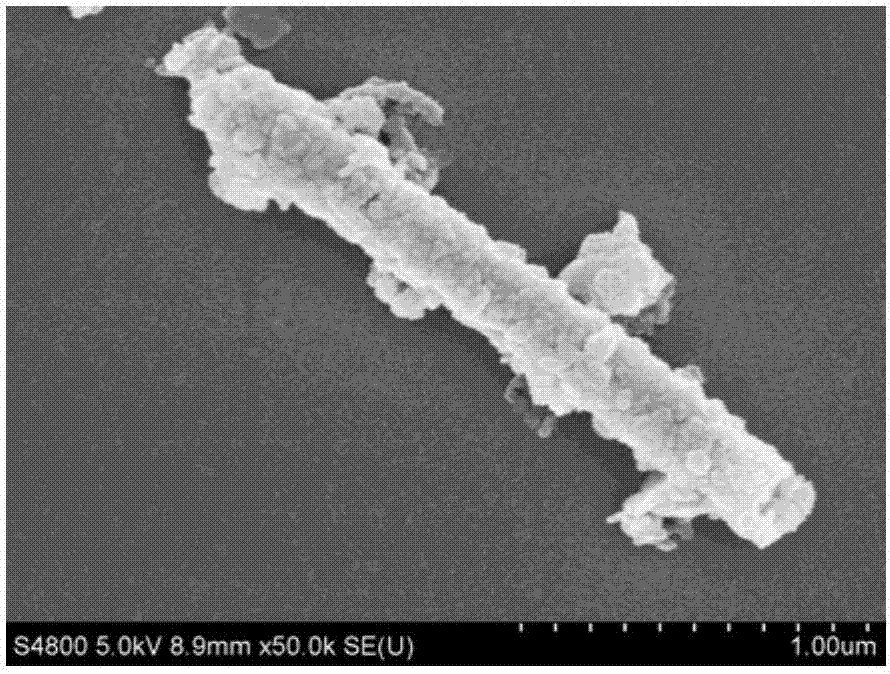

[0030] Dissolve copper nanowires of different qualities in pure N,N-dimethylformamide solution to obtain solution A, first ultrasonically for 15 minutes and stir for 10 minutes to fully dissolve the copper nanowires, and then add p-benzene with a mass ratio of 1:1.3 Diformic acid and zirconium tetrachloride were successively dissolved in N,N-dimethylformamide solution A containing different masses of copper nanowires dissolved, all dissolved evenly after stirring and ultrasonication, and there was no precipitate at the bottom of the quartz tube, and then The solution was put into microwave at 120°C for reaction. The microwave heated up at 10°C / min and reacted for 30 minutes. If the reaction time is too long, the morphology of copper nanowires will be destroyed. If the reaction time is too short, the desired MOF cannot be synthesized. Then the product UIO-66-Cu is obtained after the reaction is finished. Figure 1 shows the FESEM spectra of UIO-66, copper nanowires and UIO-66-Cu...

Embodiment 2

[0032] The operation steps of Example 1 were repeated, except that the microwave reaction was performed for 35 minutes, and the result was similar to that of Example 1, but the morphology of copper nanowires was partially destroyed. The microstructure of the sample is consistent with that of Example 1. After adding copper nanowires, the crystallinity decreases, and the diffuse reflectance results show that the composite material sample has a visible light response.

Embodiment 3

[0034] The operation steps of Example 1 were repeated, except that during the microwave reaction, the temperature was raised for 10 minutes, and the reaction temperature was 110°C. The result was similar to that of Example 1, and the morphology of copper nanowires was mostly preserved. The microstructure of the sample is consistent with that of Example 1. After adding copper nanowires, the crystallinity decreases, and the diffuse reflectance results show that the composite material sample has a visible light response.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com