Method for purifying Lycium barbarum polysaccharides

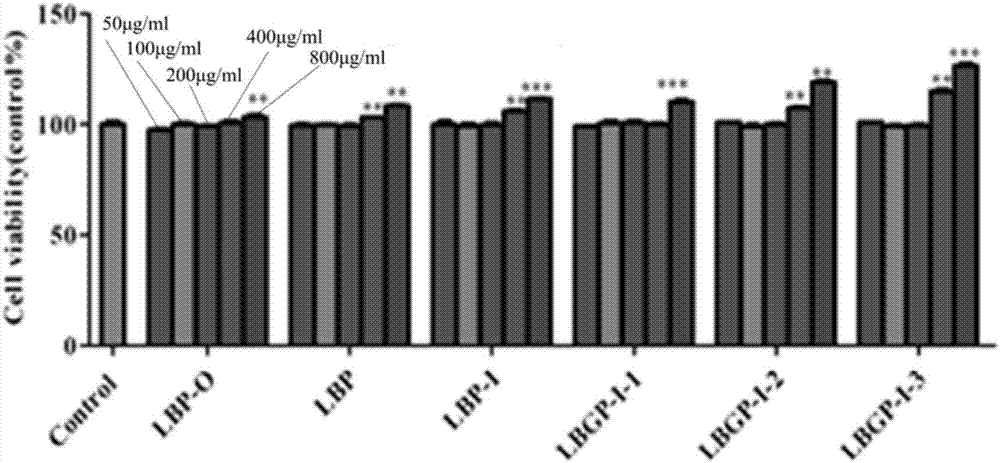

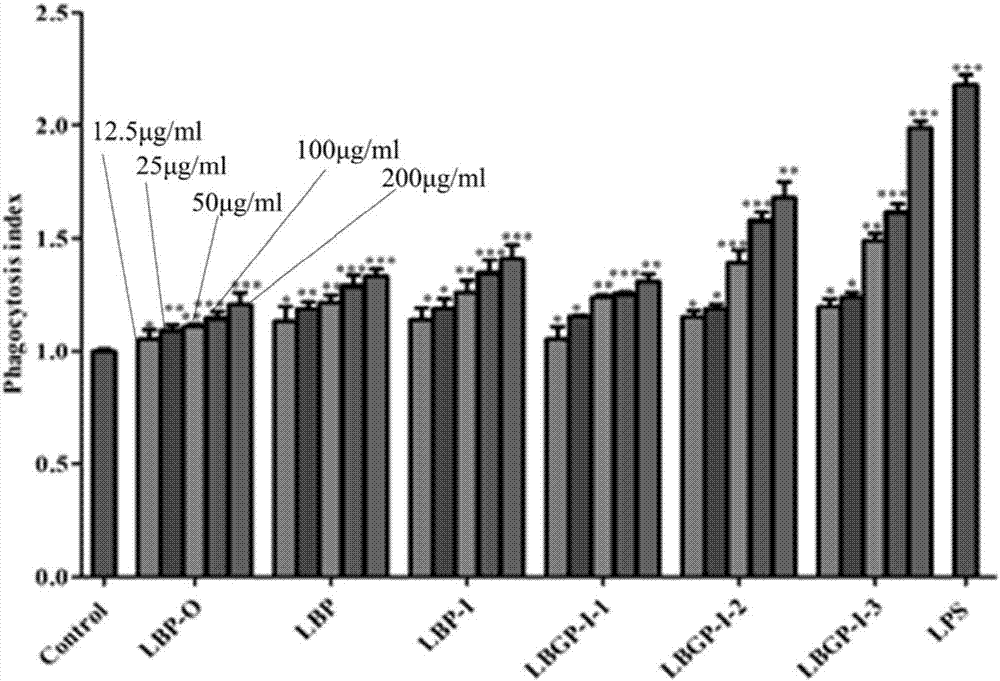

A technology of Lycium barbarum polysaccharides and components of Lycium barbarum polysaccharides, which can be used in anti-toxins, allergic diseases, drug combinations, etc., can solve the problems of difficulty in comprehensively evaluating the functions of Lycium barbarum polysaccharides, easy loss of active components, and complicated operations, and achieve strong free radicals. Cleansing and reducing power, enhanced phagocytosis, simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for refining Lycium barbarum polysaccharide, comprising the following steps:

[0043] Step 1, extraction of Lycium barbarum polysaccharide

[0044] Step 1.1, take 500g of wolfberry, crush it with a tissue masher (Jintan Xinhang JJ-2 tissue masher homogenizer), soak it in 1500mL distilled water, adjust the pH to 7.0 with 1mol / L sodium hydroxide solution, Soak for 24h, centrifuge at 8000r / min for 10min, collect the first supernatant and the first precipitation; add 750mL distilled water to the first precipitation, soak for 6h, centrifuge at 8000r / min for 10min, collect the second supernatant; combine For the first supernatant and the second supernatant, the obtained mixed solution (about 2250mL) was placed below 40°C and concentrated to 400mL by rotary evaporation; then 1600mL of absolute ethanol was added to the concentrated solution, and after 12 hours of precipitation , centrifuge at 8000r / min for 10min, collect the precipitate;

[0045] Step 1.2, add 400mL ...

Embodiment 2

[0057] A method for refining Lycium barbarum polysaccharide, comprising the following steps:

[0058] Step 1, extraction of Lycium barbarum polysaccharide

[0059] With the step 1 of embodiment 1;

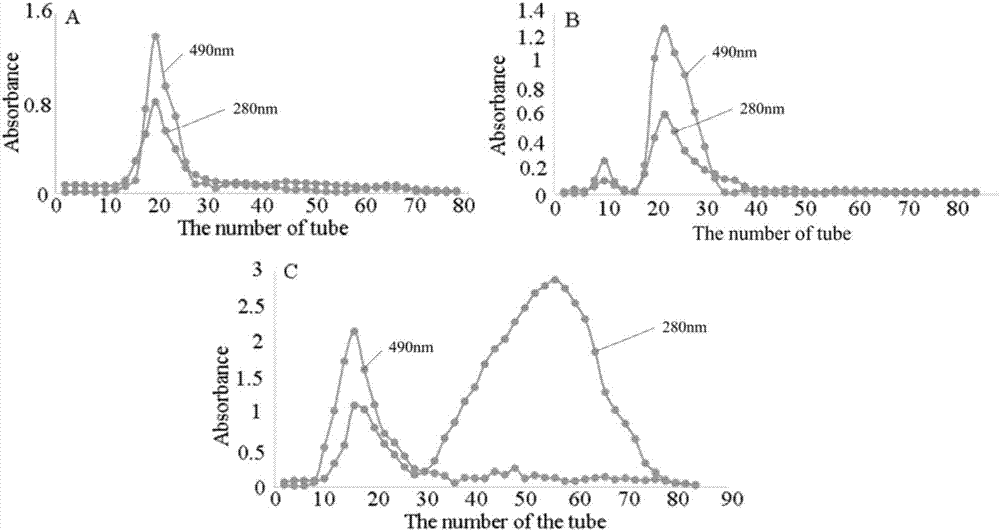

[0060] Step 2, the refining of macromolecular Lycium barbarum polysaccharide

[0061] Make the macromolecule Lycium barbarum polysaccharide into an aqueous solution with a concentration of 1g / 100mL (distilled water as the solvent), take 140mL, slowly add 60mL of absolute ethanol, so that the volume fraction of ethanol in the solution is 30%, precipitate for 12h, centrifuge at 8000r / min for 10min, collect The first polysaccharide supernatant and the first polysaccharide precipitation were reconstituted by adding 80 mL of distilled water to the first polysaccharide precipitation, centrifuged at 8000 r / min for 10 min, and the collected supernatant was freeze-dried at a temperature of -50 °C and a vacuum of 5-10Pa, the first Lycium barbarum polysaccharide fraction (LBP-I-1) was obtai...

Embodiment 3

[0069] A method for refining Lycium barbarum polysaccharide, comprising the following steps:

[0070] Step 1, extraction of Lycium barbarum polysaccharide

[0071] With the step 1 of embodiment 1;

[0072] Step 2, the refining of macromolecular Lycium barbarum polysaccharide

[0073] Make the macromolecule Lycium barbarum polysaccharide into an aqueous solution with a concentration of 1g / 100mL (the solvent is distilled water), take 35mL, slowly add 15mL of absolute ethanol, so that the volume fraction of ethanol in the solution is 30%, precipitate for 12h, centrifuge at 8000r / min for 10min, collect The first polysaccharide supernatant and the first polysaccharide precipitation were reconstituted by adding 30 mL of distilled water to the first polysaccharide precipitation, centrifuged at 8000 r / min for 10 min, and the collected supernatant was freeze-dried at a temperature of -50 °C and a vacuum of 5-10Pa, the first Lycium barbarum polysaccharide fraction (LBP-I-1) was obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com