Preparation method of ink jet printing high permeable reactive dye ink

A reactive dye, inkjet printing technology, applied in dyeing method, ink, application, etc., to improve the color depth of double-sided printing, reduce the degree of dye hydrolysis, and be suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

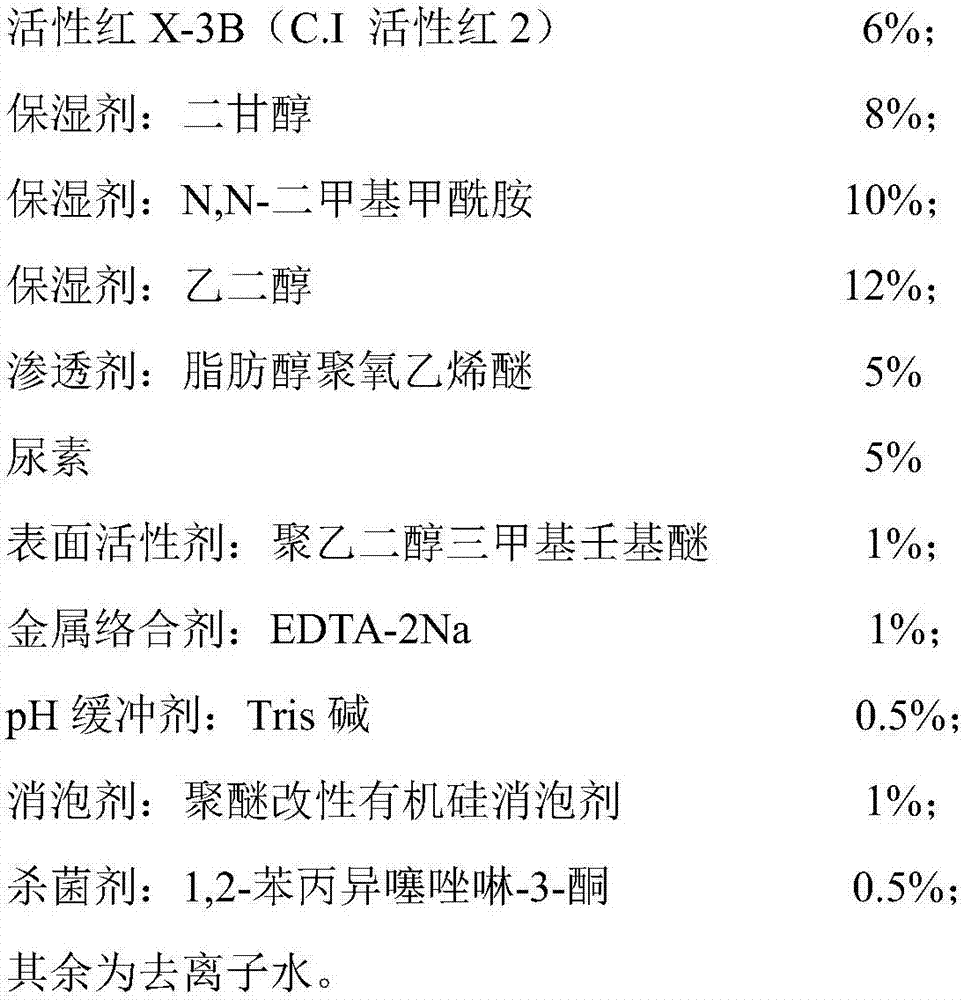

[0023] Preparation of reactive red ink:

[0024]

[0025] Add the above substances into the flask in turn, mix and stir evenly, and then filter them through 1.5 micron, 0.52 micron, and 0.2 micron filter membranes to remove impurities to prepare high-permeability inkjet printing reactive red ink.

[0026] The prepared ink was tested for printing fluency on the machine, and there was no disconnection and blockage within 24 hours, and the fluency was good. Use the prepared ink on silk fabric (100g / m 2 ) for inkjet printing (printing 5×5cm solid color blocks), steaming and fixing the color at 102°C for 20 minutes, washing in cold water, hot water, and cold water to test the color depth value of the printed fabric (K / S color measuring instrument, fabric Folding double layer), printing front K / S value: 13.6, reverse K / S value: 12.9, permeability 94.85% (permeability = fabric reverse K / S value / fabric front K / S value), strength loss rate 2%, the penetration effect is good, and t...

Embodiment 2

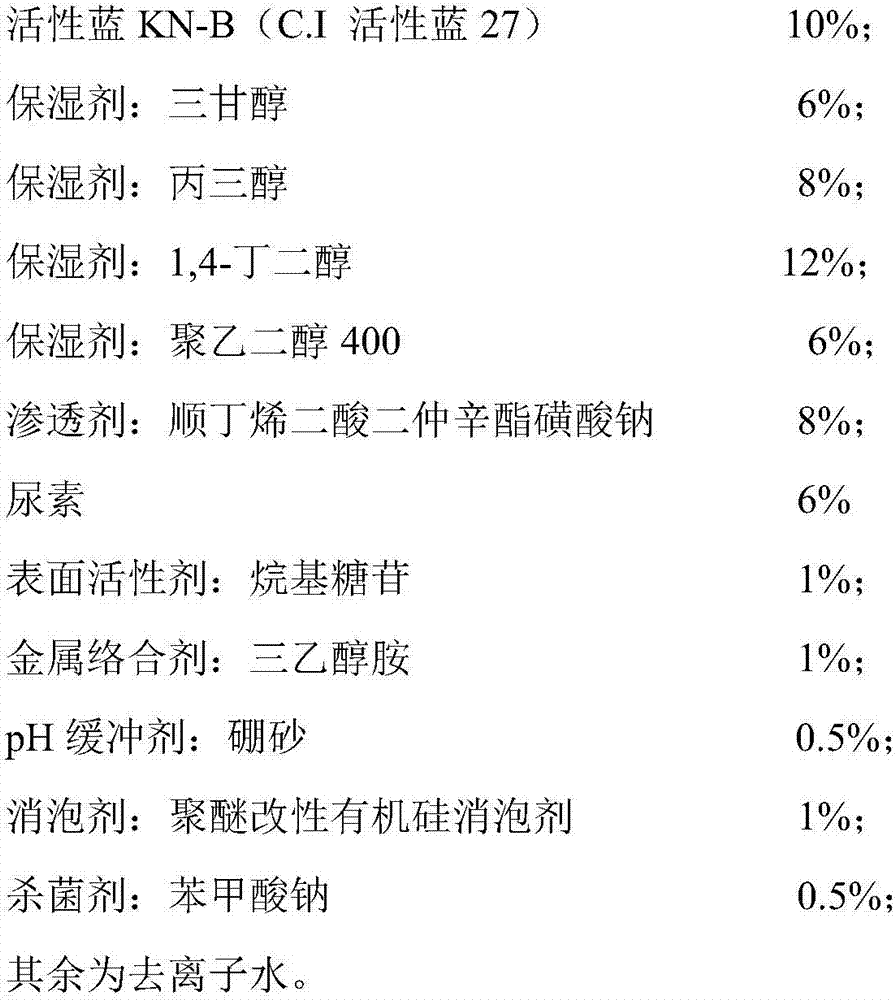

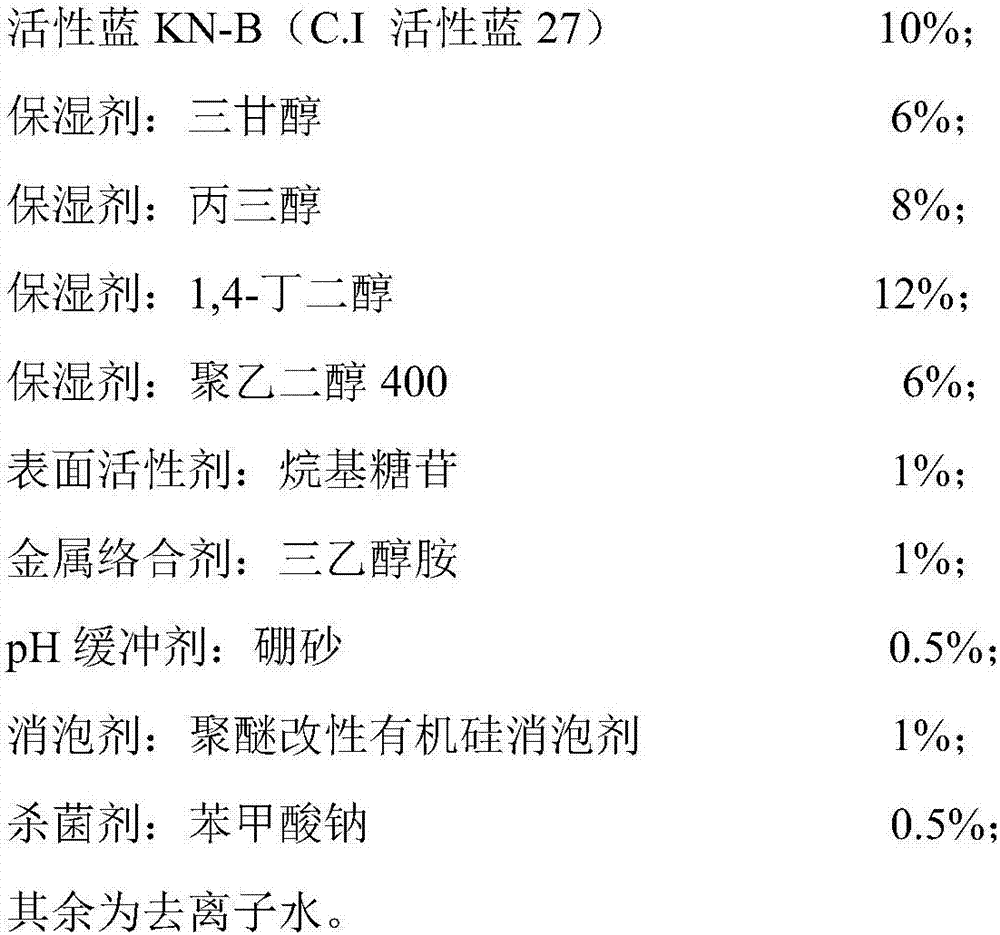

[0029] Preparation of reactive blue ink:

[0030]

[0031] Add the above substances into the flask in turn, mix and stir evenly, and then filter them through 1.5 micron, 0.52 micron, and 0.2 micron filter membranes to remove impurities to prepare high-permeability inkjet printing reactive blue ink.

[0032] The prepared ink was tested for printing fluency on the machine, and there was no disconnection and blockage within 24 hours, and the fluency was good. Use the prepared ink on silk fabric (100g / m 2 ) for inkjet printing (printing 5×5cm solid color blocks), steaming and fixing the color at 102°C for 20 minutes, washing in cold water, hot water, and cold water to test the color depth value of the printed fabric (K / S color measuring instrument, fabric Folding double layer), printing front K / S value: 12.2, reverse K / S value 11.7, permeability 95.90% (permeability = fabric reverse K / S value / fabric front K / S value), strength loss rate 2 % The penetration effect is good, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com