Yarrowia lipolytica and applications thereof

A Yarrow lipolytic yeast, ventilation fermentation technology, applied in the direction of fermentation, microorganisms, fungi, etc., can solve the problems of cumbersome steps, inability to assimilate and utilize xylose, etc., and achieve the effect of simplified process operation and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The natural breeding of embodiment 1 Yarrow lipolytica (CCTCC NO:M 2017027)

[0024] Three soil samples were collected from the poplar forest in Weishan Lake Wetland Honghe Tourist Scenic Area, Tengzhou City, Shandong Province, respectively labeled TW-1, TW-2, and TW-3. Then take 1 g each, respectively add to three 1 L Erlenmeyer flasks containing 100 ml of 350 g / l glucose for enrichment and culture for 3 days. and then diluted to 10 -8 Coating was performed on the screening plate medium I, and a total of 3978 single colonies were obtained. The obtained single colonies were spread on the screening plate medium II respectively, and a total of 27 bacterial strains that can grow with D-xylose as a carbon source were obtained.

[0025] Fermentation and breeding were carried out with fermentation medium I and fermentation medium II respectively. After 3 days of fermentation, 1ml of fermentation broth was taken, centrifuged at 5000rpm for 5min, the supernatant was diluted t...

Embodiment 2

[0026] Example 2 Yeast Yarrow lipolytica (CCTCC NO: M 2017027) fermentation production of erythritol

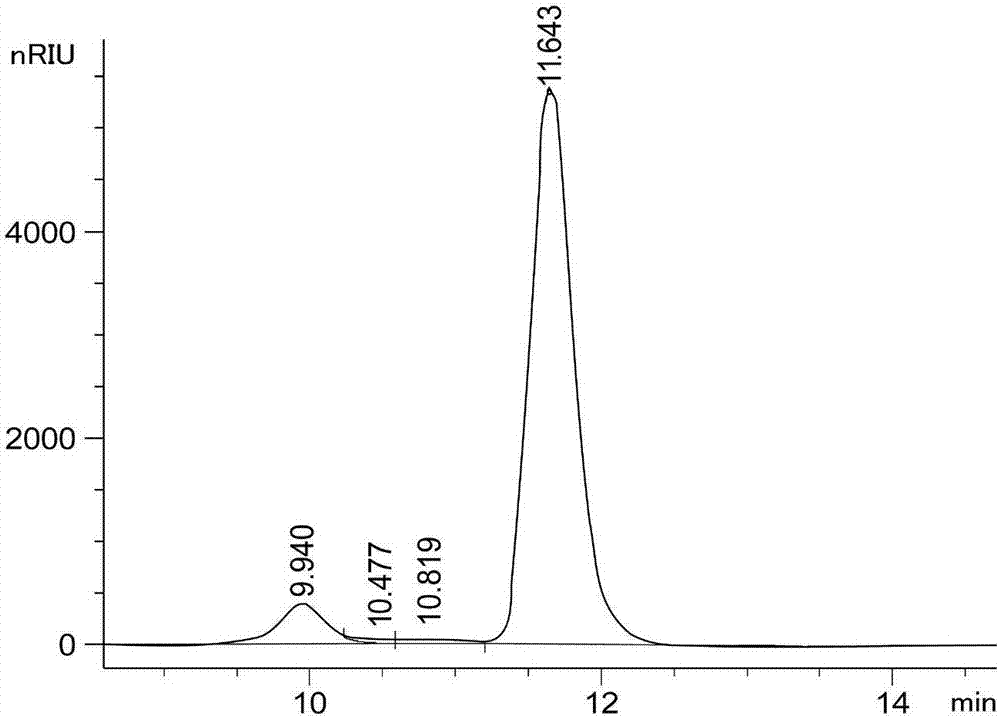

[0027] The starting strain Yarrowia Lipolytica BBE-17 stored in a glycerol tube at -80°C was activated in a 150ml Erlenmeyer flask with a liquid volume of 25ml and an inoculation volume of 2% (V / V). The basic composition is: glucose 100g / l, yeast powder 10g / l. After activation and cultivation for 24 hours, it was inserted into a 1 L baffled Erlenmeyer flask with a fermentation medium, the filling volume was 100 ml, the inoculum volume was 4% (V / V), and the rotation speed was 220 rpm. The composition of the fermentation medium is: glucose 120g / l, yeast powder 10g / l, ammonium citrate 5g / l, magnesium sulfate 0.5g / l, potassium dihydrogen phosphate 0.25g / l. After 48h of fermentation, the erythritol content measured by HPLC was 82.47g / l, figure 1 The middle peak time of 11.643min corresponds to erythritol, and the mass conversion rate of erythritol to glucose is 69.35%.

Embodiment 3

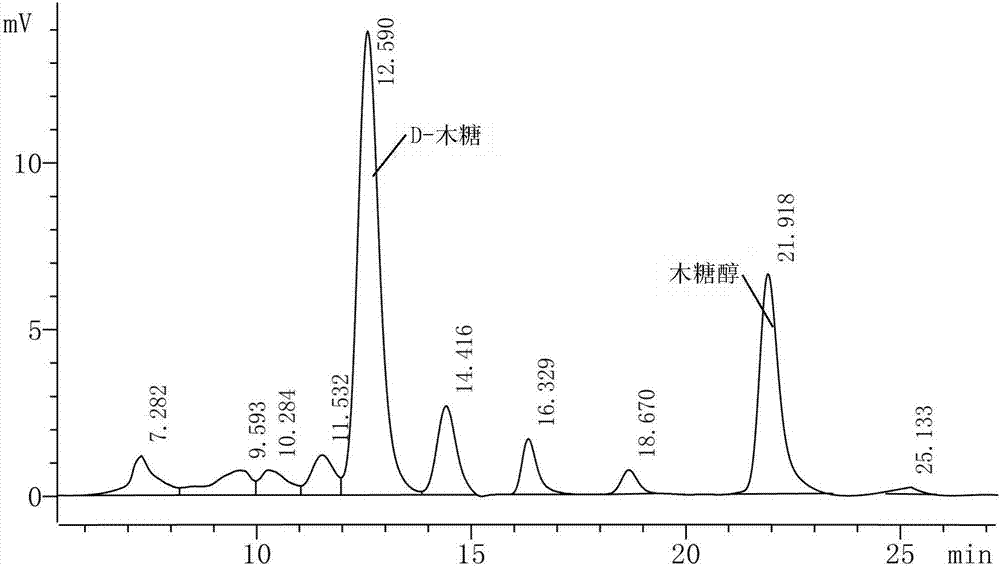

[0028] Example 3 Yarrow lipolytica (CCTCC NO:M 2017027) fermented xylitol

[0029]The starting strain Yarrowia Lipolytica BBE-17 stored in a glycerol tube at -80°C was activated in a 150ml Erlenmeyer flask with a liquid volume of 25ml and an inoculation volume of 2% (V / V). The basic composition is: glucose 100g / l, yeast powder 10g / l. After activating and culturing for 24 hours, it was inserted into a 500ml common Erlenmeyer flask equipped with a fermentation medium, the filling volume was 50ml, the inoculum volume was 2% (V / V), and the rotating speed was 180rpm. The composition of the fermentation medium is: D-xylose mother liquor (calculated as solid matter) 150g / l, yeast powder 10g / l, ammonium citrate 5g / l, magnesium sulfate 0.5g / l, potassium dihydrogen phosphate 0.25g / l. When fermented for 216 hours, the content of xylitol determined by HPLC was 39.50 g / l, and the mass conversion rate of xylitol to D-xylose was 33.35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com