Lactic acid bacteria composite microbial agent and preparation method and application thereof

A compound bacterial agent, lactic acid bacteria technology, applied in the directions of biochemical equipment and methods, applications, microorganism-based methods, etc., can solve the problems of long fermentation time, single effect, low yield, etc., and achieve improved survival rate, stable quality and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

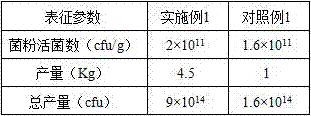

[0039] Embodiment 1 The preparation of Lactobacillus reuteri freeze-dried bacterial powder

[0040] 1. Liquid submerged fermentation culture

[0041] Inoculate 2% inoculum of Lactobacillus reuteri into 150mL seed medium in a 250mL Erlenmeyer flask at 37°C, 5% CO 2 cultured in an incubator. After 24 h, inoculate 800 mL seed medium in a 1 L Erlenmeyer flask with 3% inoculum amount, and inoculate at 37 °C, 5% CO 2 cultured in an incubator. After culturing for about 7 hours, inoculate into a 200mL fermenter with a 3% inoculum size, and contain 160mL fermentation medium.

[0042] The fermentation culture conditions are: temperature 37°C, rotation speed 50rpm, pressure 0.05MPa, ventilation rate 1.5L / H, during the fermentation process, the pH value is controlled between 5.5 and 6.5 with 30% potassium hydroxide solution, and the OD600 value of the fermentation broth and After the pH value became stable, the tank was put into the tank, and the culture time was about 8 hours. When t...

Embodiment 2

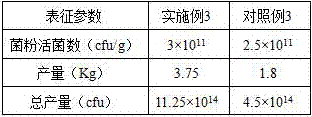

[0049] The preparation of embodiment 2 Lactobacillus plantarum freeze-dried bacteria powder

[0050] 1. Liquid submerged fermentation culture

[0051] Inoculate 2% inoculum of Lactobacillus plantarum into 150mL seed medium in a 250mL Erlenmeyer flask, at 37°C, 5% CO 2 cultured in an incubator. After 24 h, inoculate 800 mL seed medium in a 1 L Erlenmeyer flask with 3% inoculum amount, and inoculate at 37 °C, 5% CO 2 cultured in an incubator. After culturing for about 7 hours, inoculate into a 200mL fermenter with a 3% inoculum size, and contain 160mL fermentation medium.

[0052] The fermentation conditions are as follows: temperature 37°C, rotation speed 80rpm, pressure 0.05MPa, ventilation rate 0 L / H, the initial pH value of the fermentation broth is 5.8, and the pH value is controlled at about 5.8 with ammonia water during the fermentation process, with the OD600 value and pH of the fermentation broth After the value became stable, the tank was put into the tank, and the...

Embodiment 3

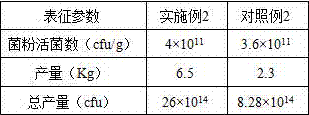

[0059] Embodiment 3 The preparation of Lactobacillus rhamnosus freeze-dried bacterial powder

[0060] 1. Liquid submerged fermentation culture

[0061] Inoculate 2% inoculum of Lactobacillus rhamnosus into 150mL seed medium in a 250mL Erlenmeyer flask and store at 37°C in 5% CO 2 cultured in an incubator. After 24 h, inoculate 800 mL seed medium in a 1 L Erlenmeyer flask with 3% inoculum amount, and inoculate at 37 °C, 5% CO 2 cultured in an incubator. After culturing for about 7 hours, inoculate into a 200mL fermenter with a 3% inoculum size, and contain 160mL fermentation medium.

[0062] The fermentation conditions are as follows: temperature 37°C, rotation speed 80rpm, pressure 0.05MPa, ventilation rate 0 L / H, the initial pH value of the fermentation broth is 5.8, and the pH value is controlled at about 5.8 with ammonia water during the fermentation process, with the OD600 value and pH of the fermentation broth After the value became stable, the tank was put into the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com