Steel surface antirust agent combination product and application thereof

A combination product and rust inhibitor technology, applied in the direction of metal material coating process, etc., can solve problems such as surprising cost, and achieve the effect of high surface uniformity, low surface roughness, and enhanced anti-rust performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

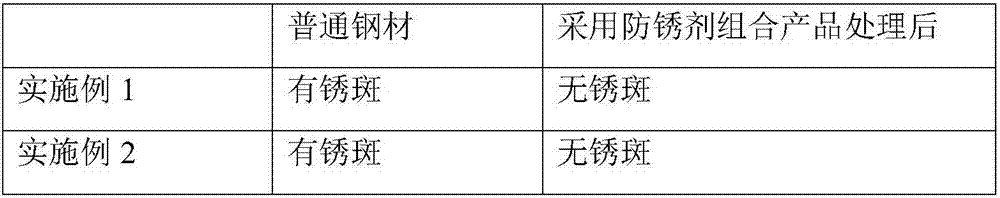

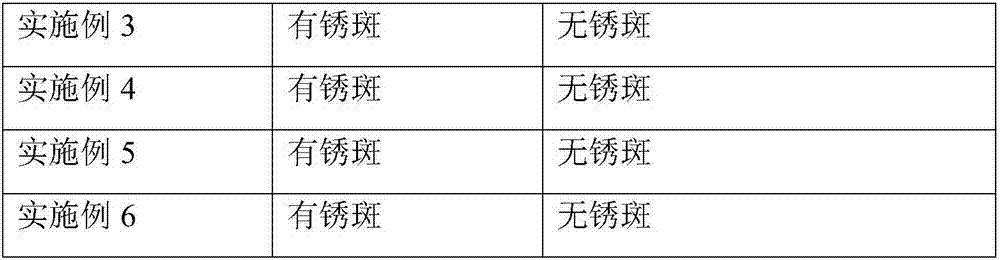

Examples

Embodiment 1

[0021] Apply a mixture of 2% potassium hydroxide, 13-16% ammonium sulfide, and 1% triethanolamine to the outer surface of the steel, then put the steel under sunlight for 1 hour, take it back, and place it in a cool place; Then use a mixed solution of 10% nitric acid and 0.1% thiourea at a temperature of 40°C to wash the steel; after washing, put it in an oven at 40°C for drying; then immerse the above steel at 250°C with a concentration of 100-150g / L ammonium chloride solution for 2 minutes, then put the steel into 150g / L zinc chloride solution at 450°C for 20 minutes, and finally place it in a passivation solution at a temperature of 30°C. passivation. The passivation solution is a mixed solution of ammonium dichromate with a concentration of 80g / L and chromic acid with a concentration of 3g / L.

Embodiment 2

[0023] Apply a mixture of 5% potassium hydroxide, 16% ammonium sulfide, and 2% triethanolamine to the outer surface of the steel, then place the steel in the sun for 2 hours, take it back, and place it in a cool place; The mixed solution of 12% nitric acid and 0.2% thiourea, the temperature is 60°C, and the steel is washed; after washing, it is placed in an oven at 60°C for drying; then the above steel is immersed at 300°C with a concentration of 150g / Into L ammonium chloride solution for 4 minutes, then put the steel into zinc chloride solution with a concentration of 180g / L at 470°C for 30 minutes, and finally put it into a passivation solution at a temperature of 32°C for passivation. The passivation solution is a mixed solution of ammonium dichromate with a concentration of 100g / L and chromic acid with a concentration of 4g / L.

Embodiment 3

[0025] Apply a mixture of 2% potassium hydroxide, 13% ammonium sulfide, and 1% triethanolamine to the outer surface of the steel, then place the steel in the sun for 2 hours, take it back, and place it in a cool place; The mixed solution of 10% nitric acid and 0.1% thiourea, the temperature is 60 ℃, and the steel is washed; after washing, it is placed in an oven at 60 ℃ for drying; then the above steel is immersed at 300 ℃ with a concentration of 100g / Into L ammonium chloride solution for 4 minutes, then put the steel into the zinc chloride solution with a concentration of 150g / L at 470°C for 30 minutes, and finally put it into the passivation solution with a temperature of 32°C for passivation. The passivation solution is a mixed solution of ammonium dichromate with a concentration of 80g / L and chromic acid with a concentration of 3g / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com