Perovskite thin film battery preparation method

A thin film battery and perovskite technology, applied in the field of solar cells, can solve the problems of thin film corrosion, low repeatability, poor coating quality, etc., and achieve the effects of low preparation process cost, avoiding thin film roughness, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method for a perovskite thin film battery, comprising the following steps:

[0034] Step 1: Preparation of precursor solution:

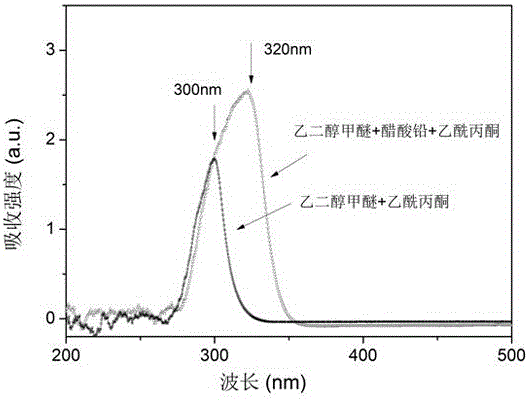

[0035] (1-1) Dissolve lead acetate and methyl ammonium iodide in ethylene glycol methyl ether, the molar ratio of lead acetate to methyl ammonium iodide is 1~1.1:3, adjust the amount of ethylene glycol methyl ether, so that The lead ion concentration is controlled at 0.7-0.8mol / L, and a clear solution A is obtained after stirring;

[0036] (1-2), add acetylacetone to solution A, the molar ratio of lead acetate to acetylacetone is 1~1.1:1~1.1, and obtain solution B after stirring;

[0037] (1-3) Dissolve fullerene derivative PCBM powder in anhydrous chlorobenzene solution, and control the mass ratio of PCBM to 20-22 mg / ml by adjusting the content of chlorobenzene solution to obtain solution C;

[0038] Step 2: Preparation of thin film battery:

[0039] (2-1) Use commercial poly(3,4-dioxyethylthiophene) solution to perform spin-...

Embodiment 1

[0048] Step 1: Preparation of Precursor Solution

[0049] Lead acetate, ammonium iodide are dissolved in ethylene glycol methyl ether solution, control lead acetate, the molar ratio of ammonium iodide is 1.07: 3, obtain clear solution A after stirring, by regulating the consumption of ethylene glycol methyl ether , so that the concentration of lead ions is controlled at 0.7mol / L;

[0050] Add acetylacetone in solution A, so that the moles of lead acetate and acetylacetone must be: lead acetate: acetylacetone=1:1, obtain clear solution B after stirring;

[0051] Dissolving fullerene derivative PCBM powder in anhydrous chlorobenzene solution, controlling the mass ratio of PCBM to 22 mg / ml by adjusting the content of chlorobenzene solution, to obtain solution C;

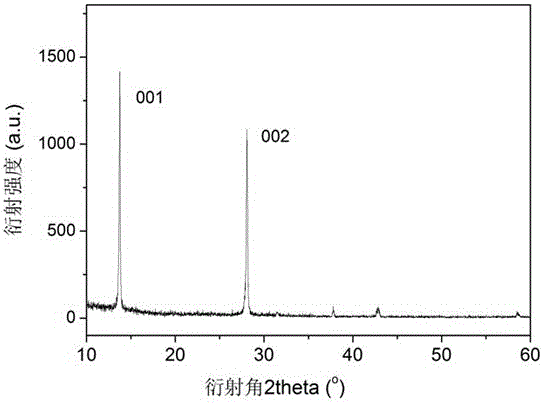

[0052] Step 2: Preparation of Thin Film Battery

[0053] Commercial poly(3,4-dioxyethylthiophene) solution (referred to as PEDOT solution) was used to spin-coat the glass coated with ITO conductive film. The spin-coat...

Embodiment 2

[0056] Lead acetate, methyl ammonium iodide are dissolved in ethylene glycol methyl ether solution, control lead acetate, the molar ratio of methyl iodide ammonium is 1: 3, obtain clear solution A after stirring, by regulating the consumption of ethylene glycol methyl ether , so that the lead ion concentration is controlled at 0.7mol / L; Add acetylacetone in solution A, so that the moles of lead acetate and acetylacetone must be: lead acetate: acetylacetone=1:1, after stirring, obtain clear solution B; fullerene Derivative PCBM powder was dissolved in anhydrous chlorobenzene solution, and the mass ratio of PCBM was controlled to be 22 mg / ml by adjusting the content of chlorobenzene solution to obtain solution C.

[0057] Commercial poly(3,4-dioxyethylthiophene) solution (referred to as PEDOT solution) was used to spin-coat the glass coated with ITO conductive film. The spin-coating speed was controlled at 3000 rpm, and the spin-coating time was Controlled at 50s, the resulting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com