Procaterol hydrochloride granule and preparation method thereof

A technology of procaterol hydrochloride, granules, applied in the field of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

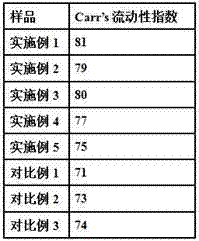

Examples

Embodiment 1

[0029] Example 1 Procaterol hydrochloride granule and its preparation process

[0030] Prescription: Procaterol hydrochloride 2g, lactose 13970g, hydroxypropyl methylcellulose 620g, croscarmellose sodium 550g by weight, calcium chloride 5080g, diethyl palmitoyl aspartate 2g .

[0031] Preparation Process:

[0032] 1) Take the prescribed amount of calcium chloride and pulverize it, pass through a 300-mesh sieve to obtain calcium chloride fine powder for later use;

[0033] 2) Take the prescribed amount of procaterol hydrochloride, lactose, hydroxypropyl methylcellulose, croscarmellose sodium, diethyl palmitoyl aspartate, mix by ball milling, and add 5ml of water per 1g of powder Add sterile water for injection at 900rpm to the mixed powder and stir for 0.3h to obtain a suspension;

[0034] 3) Use the calcium chloride fine powder obtained in step 1) as an excipient, and the suspension obtained in step 2) as a spray liquid, spray granulation on the top of the fluidized bed, th...

Embodiment 2

[0036] Example 2 Procaterol hydrochloride granule and its preparation process

[0037] Prescription: Procaterol hydrochloride 3 g, lactose 12650 g, hydroxypropyl methylcellulose 750 g, croscarmellose sodium 650 g by weight, calcium chloride 3940 g, diethyl palmitoyl aspartate Esters 4 g.

[0038] Preparation Process:

[0039] 1) Take the prescribed amount of calcium chloride and pulverize it, pass through a 300-mesh sieve to obtain calcium chloride fine powder for later use;

[0040] 2) Take the prescribed amount of procaterol hydrochloride, lactose, hydroxypropyl methylcellulose, croscarmellose sodium, diethyl palmitoyl aspartate, mix by ball milling, and add 5ml of water per 1g of powder Add sterile water for injection at 850rpm to the mixed powder and stir for 0.3h to obtain a suspension;

[0041] 3) Use the calcium chloride fine powder obtained in step 1) as an excipient, and the suspension obtained in step 2) as a spray liquid, spray granulation on the top of the fluid...

Embodiment 3

[0043] Example 3 Procaterol hydrochloride granule and its preparation process

[0044] Prescription: Procaterol hydrochloride 2 g, lactose 12800 g, hydroxypropyl methylcellulose 700 g, croscarmellose sodium 600 g by weight, calcium chloride 4500 g, diethyl palmitoyl aspartate 3g.

[0045] Preparation Process:

[0046] 1) Take the prescribed amount of calcium chloride and pulverize it, pass through a 300-mesh sieve to obtain calcium chloride fine powder for later use;

[0047] 2) Take the prescribed amount of procaterol hydrochloride, lactose, hydroxypropyl methylcellulose, croscarmellose sodium, diethyl palmitoyl aspartate, mix by ball milling, and add 5ml of water per 1g of powder Proportion Add sterile water for injection at 800 rpm to the mixed powder and stir for 0.3 h to obtain a suspension;

[0048] 3) Use the calcium chloride fine powder obtained in step 1) as an excipient, and the suspension obtained in step 2) as a spray liquid, spray granulation on the top of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com