Preparation method of core-shell type carrier using TiO2 as shell layer

A core-shell type, carrier technology, applied in catalyst activation/preparation, separation method, catalyst carrier, etc., can solve the problems of easy penetration of active components into the substrate, uneven thickness of the shell layer, low mechanical strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

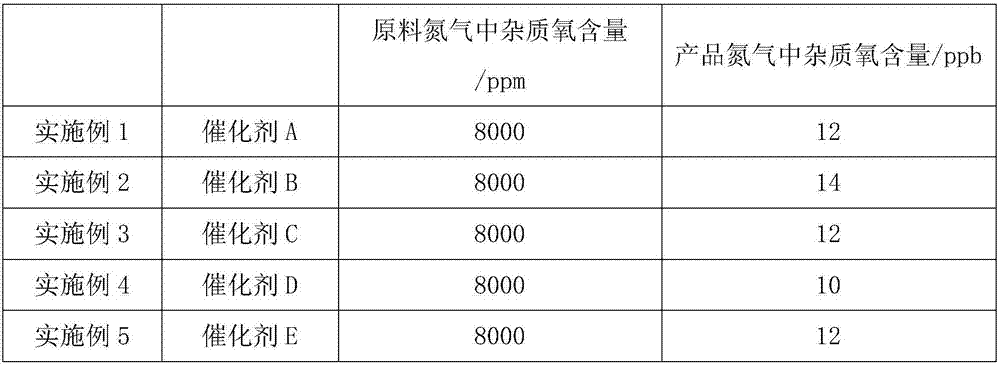

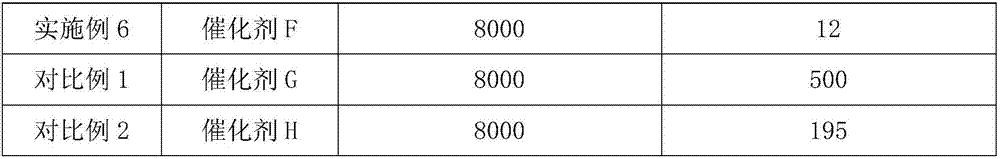

Examples

Embodiment 1

[0021] A TiO 2 A preparation method for a core-shell carrier of the shell, comprising:

[0022] (1) At room temperature, mix silica sol, aluminum sol, titanium sol, squash gum, CMC (sodium carboxymethyl cellulose) and water, and stir evenly to obtain a glue solution, wherein, in the glue solution, SiO 2 、Al 2 o 3 、TiO 2 , the mass ratio of Tianqing glue, CMC and water is 0.1:0.1:10:1:0.1:100;

[0023] (2) Choose a spherical α-Al with a diameter of 2mm 2 o 3 Put it in the sugar coating machine as the base material, spray the glue solution on the base material with the mass ratio of the glue solution and the base material as 1:25, and then roll it in the sugar coating machine for 0.5h, so that the glue solution can be evenly coated On the outside of the substrate, a carrier precursor is obtained, and titanium dioxide powder is sprayed on the carrier precursor; wherein, the titanium dioxide powder is 300 mesh anatase titanium dioxide powder;

[0024] (3) After spraying tit...

Embodiment 2

[0026] A TiO 2 A preparation method for a core-shell carrier of the shell, comprising:

[0027] (1) At room temperature, mix silica sol, aluminum sol, titanium sol, squash gum, CMC and water, stir evenly to obtain a glue solution, wherein, in the glue solution, SiO 2 、Al 2 o 3 、TiO 2 , the mass ratio of Tianqing glue, CMC and water is 10:10:0.1:0.1:1:100;

[0028] (2) Select a spherical δ-Al with a diameter of 5mm 2 o 3 Place the base material in a sugar-coating machine, spray the glue solution onto the base material in an amount of 13:25 in mass ratio between the glue solution and the base material, then roll in the sugar-coating machine for 3 hours, so that the glue solution is evenly coated on the On the outside of the substrate, a carrier precursor is obtained, and titanium dioxide powder is sprayed on the carrier precursor; wherein, the titanium dioxide powder is 400 mesh anatase titanium dioxide powder;

[0029] (3) After spraying titanium dioxide powder, calcine ...

Embodiment 3

[0031] A TiO 2 A preparation method for a core-shell carrier of the shell, comprising:

[0032] (1) At room temperature, mix silica sol, aluminum sol, titanium sol, squash gum, CMC and water, stir evenly to obtain a glue solution, wherein, in the glue solution, SiO 2 、Al 2 o 3 、TiO 2 , the mass ratio of Tianqing glue, CMC and water is 1:1:1:1:1:100;

[0033] (2) Choose a spherical θ-Al with a diameter of 3mm 2 o 3Place the base material in a sugar coating machine, spray the glue solution onto the base material in an amount of 7:25 in the mass ratio of the glue solution to the base material, and then roll it in the sugar coating machine for 1 hour, so that the glue solution can be evenly coated on the On the outside of the substrate, a carrier precursor is obtained, and titanium dioxide powder is sprayed on the carrier precursor; wherein, the titanium dioxide powder is 300 mesh anatase titanium dioxide powder;

[0034] (3) After spraying titanium dioxide powder, it is ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com