Aqueous epoxy resin emulsion synthesized with mono-isocyanate polyoxyethylene monomethyl ether monomers

A technology of polyoxyethylene monomethyl ether and monoisocyanate, which is applied in the field of water-based epoxy emulsion, and can solve the problems of difficult control of the preparation steps and high preparation cost of the chemical modification method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

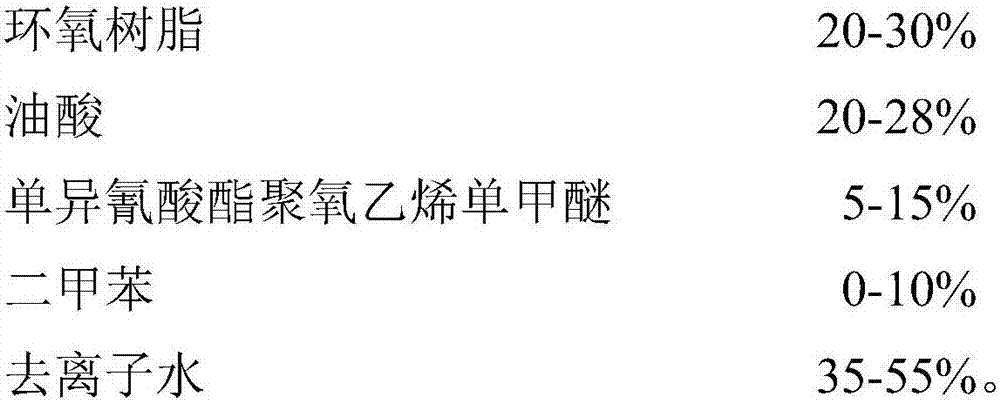

[0023] (1) The water-based epoxy grease emulsion is made of the following raw materials in mass percentage:

[0024]

[0025] Raise the temperature of the mixture of epoxy resin E20 and linoleic acid to 200°C for esterification until the acid value is 3-20, cool down to 120°C, vacuum dehydrate to reduce the mass water content in the resin to below 0.1%, and continue to cool down to 70°C ℃, then add monoisocyanate polyoxyethylene monomethyl ether, keep the temperature for 5 hours, and add deionized water dropwise after the reaction until the phase is reversed to obtain a stable emulsion.

[0026] (2) Monoisocyanate polyoxyethylene monomethyl ether is made of the following raw materials in mass percentage:

[0027] 2,4-Toluene diisocyanate 20%

[0028] Polyethylene glycol monomethyl ether 80%

[0029] Mix 2,4-toluene diisocyanate and polyethylene glycol monomethyl ether, heat up to 80°C for 6 hours, and cool down to room temperature naturally to obtain monoisocyanate polyox...

Embodiment 2

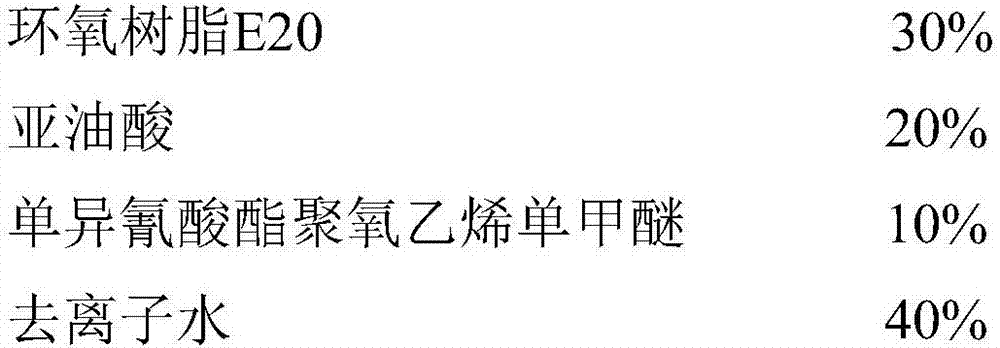

[0031] (1) The water-based epoxy grease emulsion is made of the following raw materials in mass percentage:

[0032]

[0033] Heat up the mixture of epoxy resin 604, linoleic acid, soybean oil and xylene solvent to 180°C for esterification until the acid value is 3-20, cool down to 100°C, vacuum remove xylene and water, so that the mass in the resin contains Reduce the water content to below 0.1%, continue to cool down to 85°C, then add monoisocyanate polyoxyethylene monomethyl ether, and keep it warm for 4 hours. After the reaction, add deionized water dropwise until the phase is reversed to obtain a stable emulsion.

[0034] (2) Monoisocyanate polyoxyethylene monomethyl ether is made of the following raw materials in mass percentage:

[0035] 2,4-Toluene diisocyanate 15%

[0036] Polyethylene glycol monomethyl ether 85%

[0037] Mix 2,4-toluene diisocyanate and polyethylene glycol monomethyl ether, heat up to 100°C for 5 hours, and cool down to room temperature naturall...

Embodiment 3

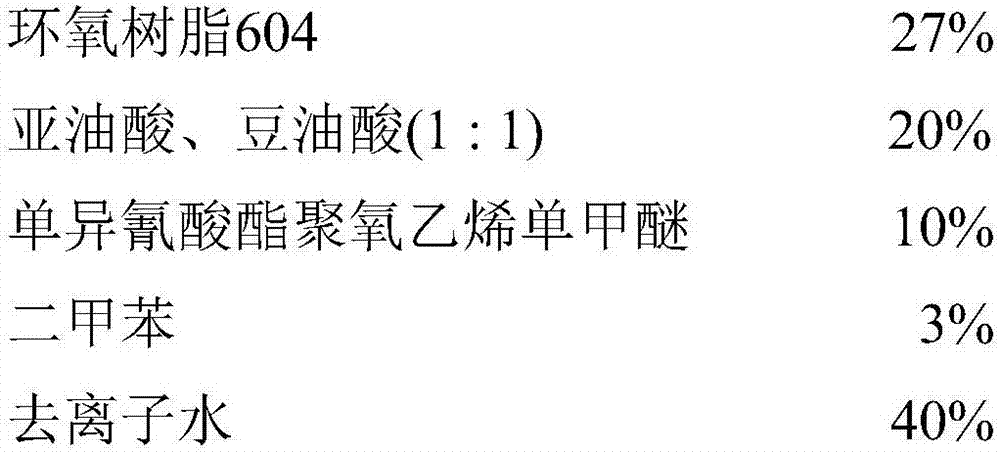

[0039] (1) The water-based epoxy grease emulsion is made of the following raw materials in mass percentage:

[0040]

[0041] Heat up the mixture of epoxy resin E20, oleic acid, soybean oil and xylene solvent to 220°C to esterify to an acid value of 3-20, cool down to 120°C, remove xylene and water in a vacuum to reduce the mass water content in the resin Reduce to below 0.1%, continue to cool down to 80°C, then add monoisocyanate polyoxyethylene monomethyl ether, keep warm for 4 hours, add deionized water dropwise after the reaction, until the phase is reversed to obtain a stable emulsion.

[0042] (2) Monoisocyanate polyoxyethylene monomethyl ether is made of the following raw materials in mass percentage:

[0043] 2,4-Toluene diisocyanate 15%

[0044] Polyethylene glycol monomethyl ether 85%

[0045] Mix 2,4-toluene diisocyanate and polyethylene glycol monomethyl ether, heat up to 90°C for 5 hours, and cool down to room temperature naturally to obtain monoisocyanate po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com