A kind of tpo car interior material with simulated suture and preparation method thereof

A technology of automotive interior and stitching, applied in the field of automotive interior materials, can solve the problem that the skin cannot be composited to the skeleton, and achieve the effects of shortening the manufacturing time, reducing the scrap rate, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

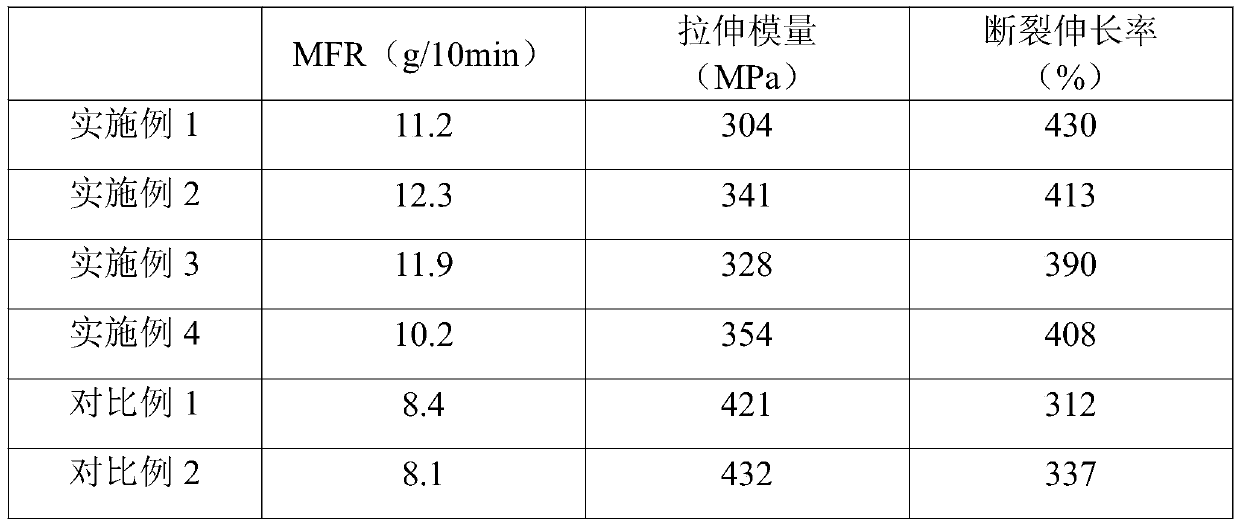

Examples

Embodiment 1

[0026] A TPO automotive interior material with simulated sutures, comprising a sponge layer, a TPO skin layer and a paint layer from bottom to top; the TPO skin layer is prepared by extruding TPO raw materials; the TPO The raw materials include the following components by weight: 30 parts of polypropylene, 15 parts of low-density polyethylene, 9 parts of polyurethane, 50 parts of EPDM rubber, 16 parts of rosin resin, 12 parts of talcum powder, 4 parts of color masterbatch, 1 part of magnesium hydroxide, 1 part of histamines, and 1 part of aromatic amines.

[0027] The foaming sponge comprises the following components by weight: 50 parts of polypropylene, 30 parts of PEO, 20 parts of EPDM rubber, and 25 parts of foaming agent.

[0028] The foaming agent comprises the following components in parts by weight: 10 parts of azodicarbonamide, 3 parts of p-toluenesulfonyl hydrazide, 30 parts of polyethylene glycol, 12 parts of triethanolamine, 3 parts of sodium bicarbonate, pentaeryth...

Embodiment 2

[0034] A TPO automotive interior material with simulated sutures, comprising a sponge layer, a TPO skin layer and a paint layer from bottom to top; the TPO skin layer is prepared by extruding TPO raw materials; the TPO The raw materials include the following components by weight: 20 parts of polypropylene, 20 parts of low-density polyethylene, 12 parts of polyurethane, 40 parts of nitrile rubber, 12 parts of terpene resin, 14 parts of wollastonite, and 1 part of aluminum hydroxide 1 part of histamines.

[0035] The foaming sponge comprises the following components in parts by weight: 40 parts of polypropylene, 40 parts of SEBS, 10 parts of EPDM rubber, and 30 parts of foaming agent.

[0036] The foaming agent comprises the following components in parts by weight: 5 parts of azodicarbonamide, 5 parts of p-toluenesulfonyl hydrazide, 25 parts of polyethylene glycol, 5 parts of triethanolamine, 5 parts of sodium bicarbonate, pentaerythritol 3 copies.

[0037] The preparation met...

Embodiment 3

[0042] A TPO automotive interior material with simulated sutures, comprising a sponge layer, a TPO skin layer and a paint layer from bottom to top; the TPO skin layer is prepared by extruding TPO raw materials; the TPO The raw materials include the following components by weight: 40 parts of polypropylene, 10 parts of low-density polyethylene, 5 parts of polyurethane, 55 parts of butyl rubber, 12 parts of hydrocarbon resin, 8 parts of mica, 8 parts of color masterbatch, polymer 2 parts of amine phosphate, 1 part of histamines, 2 parts of hindered phenols.

[0043] The foamed sponge comprises the following components in parts by weight: 60 parts of polypropylene, 20 parts of expanded polystyrene, 10 parts of EPDM rubber, and 30 parts of foaming agent.

[0044] The foaming agent comprises the following components in parts by weight: 15 parts of azodicarbonamide, 1 part of p-toluenesulfonyl hydrazide, 25 parts of polyethylene glycol, 15 parts of triethanolamine, 1 part of sodium bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com