Novel LED bracket and preparation process thereof

A technology for an LED bracket and a manufacturing process, applied in the field of LED brackets, can solve the problems of restricting the popularization and use of LED brackets, reducing the service life of LED lamps, unfavorable bracket processing and use, etc., so as to enhance the performance of anti-light decay and improve air tightness. , Good rigidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The novel LED support of present embodiment is made up of the raw material of following weight:

[0034] 425g polysulfone resin, 75g rutile titanium oxide;

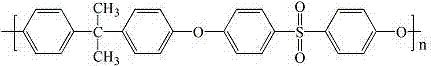

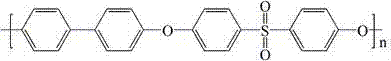

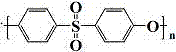

[0035] Among them, the polysulfone resin is made by mixing polyphenylsulfone, polysulfone and polyethersulfone, and the weight ratio of the three is 1:2:3;

[0036] In the present embodiment, also contain 1.32g antioxidant and 3.3g thermostabilizer in the component; Wherein, antioxidant is the mixture of phenolic antioxidant, phosphorus antioxidant, and the ratio of the weight of the two is 1: 1;

[0037] In the present embodiment, also include 0.066g pigment, 1.32g release agent as additive in the component;

[0038] The preparation process of the above-mentioned LED bracket is as follows:

[0039] Weigh 425g of polysulfone resin, 75g of rutile titanium oxide, 1.32g of antioxidant, 3.3g of thermal stabilizer and the pigment and release agent of the formulation amount, fully mix the above raw materials, then dro...

Embodiment 2

[0041] The novel LED support of present embodiment is made up of the raw material of following weight:

[0042] Polysulfone resin 360g, reinforcement modifier 100g, anatase titanium oxide 100g

[0043] Wherein, the polysulfone resin is formed by mixing polysulfone and polyethersulfone, and the weight ratio of the two is 1:3;

[0044] Wherein, the reinforcing modifier is a mixture of wollastonite, potassium titanate fiber and glass fiber, and the weight ratio of the three is 1:2:4;

[0045] In the present embodiment, also contain 20g antioxidant and 33g heat stabilizer in the component; Wherein, antioxidant is the mixture in phenolic antioxidant, sulfur antioxidant, and its ratio by weight of the two is 1:2 ;

[0046] In the present embodiment, also comprise the mixture of 12.6g pigment, 6.6g release agent, 6.6g ultraviolet absorber in the component;

[0047] The preparation process of the above-mentioned LED bracket is as follows:

[0048] Weigh 360g of polysulfone resin, ...

Embodiment 3

[0050] The novel LED support of present embodiment is made up of the raw material of following weight:

[0051] Polysulfone resin 510g, reinforcement modifier 110g, titanium oxide 100g

[0052] Among them, the polysulfone resin is made by mixing polyphenylsulfone and polyethersulfone, and the weight ratio of the two is 1:3;

[0053] Wherein, the reinforcing modifier is a mixture of wollastonite, potassium titanate fiber, glass fiber, zinc oxide fiber, sodium titanate fiber, aluminum borate fiber, and silicon nitride fiber;

[0054] Among them, titanium oxide is a mixture of anatase titanium oxide, rutile titanium oxide and monoclinic titanium oxide;

[0055] In the present embodiment, also contain 7.2g antioxidant and 7.2g thermal stabilizer in the component; Wherein, antioxidant is the mixture of phenolic antioxidant, phosphorus antioxidant, sulfur antioxidant, its three The weight ratio is 1:1:1;

[0056] In the present embodiment, also comprise the mixture of 2.16g pigme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com