Method for avoiding microalgae photoinhibition and improving astaxanthin yield

A technology of astaxanthin and photoinhibition, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as unfavorable astaxanthin production, and achieve the effect of various means and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097] Embodiment 1. Transition process makes the state of microalgae cell change

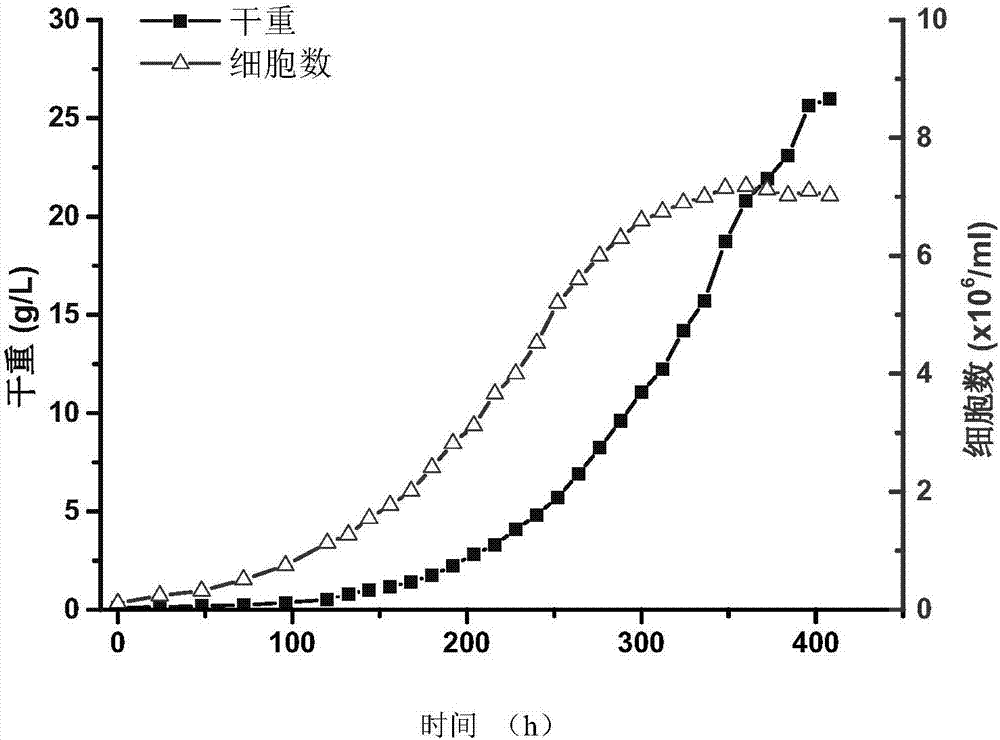

[0098] Such as figure 1 As shown, in the first stage of culture, high-density Haematococcus pluvialis cells were obtained by heterotrophic culture. Add the transition medium and water to 1L in the 1L bioreactor and steam sterilize it, then insert 12ml of high-density (26g / L) Haematococcus pluvialis heterotrophically obtained cells when the temperature drops to 25°C, Start the transition culture, maintain the temperature at 28-38°C, the air flow rate is 1vvm, artificially illuminate for 24 hours, and the light intensity on each side is about 50klx.

[0099] During cultivation, 1% carbon dioxide was fed intermittently to keep the pH at 8-9. Promote microalgae to begin to adapt to the stress environment. After 144 hours, the cells changed from chlamydospores to green cells, and the transition process ended.

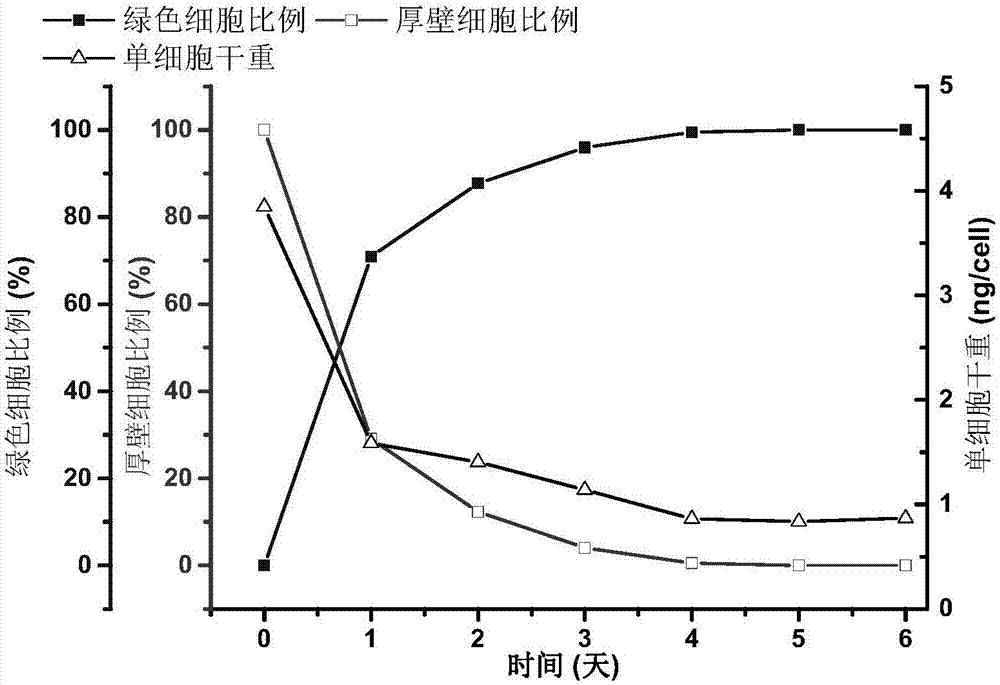

[0100] figure 2 Shows the transition culture process of Haematococcus pluvialis i...

Embodiment 2

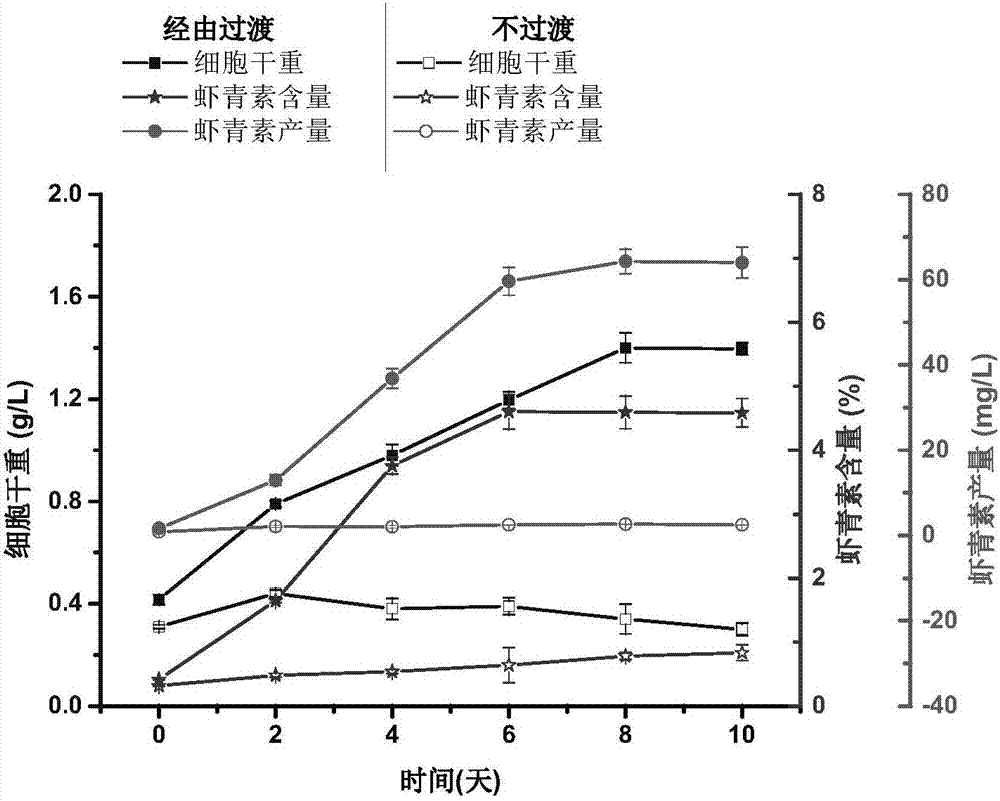

[0101] Example 2. The culture method through the transition process makes the cell dry weight increase and the astaxanthin production increase

[0102] In this example, the microalgae cells are cultured in the first stage, then undergo the transitional process of the present invention, and then conduct cell induction, and compare it with direct cell induction without the transitional process of the present invention.

[0103] image 3 Shows the comparison of Haematococcus pluvialis cells with and without the transition process in a 1L bioreactor induction culture for 10 days. Depend on image 3 It can be seen that after 10 days of light-induced culture, the dry weight of the cells after the transition process reached 1.4g / L, the astaxanthin increased to 4.6%, and the astaxanthin output reached 64mg / L. After 10 days of light-induced culture of Haematococcus pluvialis cells without the transition process, the dry weight of the cells after the transition process only reached ...

Embodiment 3

[0105] Embodiment 3. Changes in the intracellular photosynthetic system of the cells treated by the transition process

[0106] Figure 4 It shows that the difference between the intracellular photosynthetic system of the cells treated by the transition process and the control is the difference of the electron transfer efficiency (ETR) of the intracellular photosynthetic system II of each treatment (Figure A), the difference of the non-photochemical quenching (NPQ) Difference (Panel B), photosynthetic efficiency Y(II) of photosystem II (Panel C) and other non-photochemical energy (Y(NO), Diagram D) differences. The above results indicated that the efficiency of photosynthetic system II in the cell was improved through the transitional process, especially the photosynthetic system was significantly restored by the increase of nitrogen during the transitional process. The non-photochemical quenching part is relatively small, indicating that the cells have a strong ability to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com