Nonreciprocal spin-wave heterojunction waveguide material and preparation method and application thereof

A heterojunction, spin wave technology, applied in the direction of waveguide, material selection, waveguide type devices, etc., can solve the problems of difficult to change, the non-reciprocity of spin wave transmission is not obvious, and achieve a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

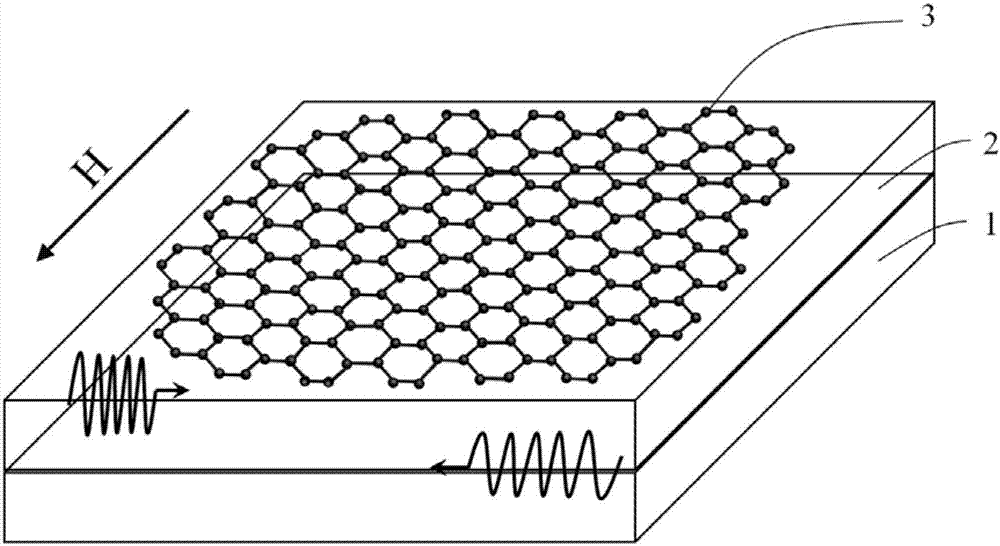

[0030] A non-reciprocal spin wave heterojunction waveguide material, which includes GGG (gadolinium gallium garnet) single crystal substrate and YIG / graphene heterojunction material, grown on the GGG single crystal substrate by liquid phase epitaxy High-quality YIG film, on the YIG film, transfer the single-layer graphene grown by the chemical vapor deposition method to the high-quality YIG film, and dry it to form a YIG / graphene heterojunction material. The YIG (yttrium iron pomegranate Stone) thin film is single crystal thin film, and thickness is at 100 nanometers, and described single-layer graphene utilizes vapor phase deposition method to grow and obtains, and described YIG / graphene heterojunction material maximum diameter is 3 inches.

[0031] The preparation method of above material, comprises the following steps:

[0032] S1: Choose high purity (higher than 99.99%) Fe 2 o 3 and Y 2 o 3 As a raw material, a high-quality YIG thin film is grown on a GGG single crysta...

Embodiment 2

[0038] A non-reciprocal spin-wave heterojunction waveguide material, which includes a GGG (gadolinium gallium garnet) single crystal substrate and a YIG / graphene heterojunction material, is deposited on a GGG single crystal using pulsed laser deposition (PLD) Growth high-quality YIG thin film on the substrate, on the YIG thin film, the single-layer graphene that vapor deposition method is grown is transferred on the high-quality YIG thin film, drying treatment forms YIG / graphene heterojunction material, described YIG (yttrium (yttrium) Iron garnet) film is a single crystal film with a thickness of 500 nanometers. The single-layer graphene is grown by vapor deposition method, and the maximum diameter of the YIG / graphene heterojunction material is 3 inches.

[0039] The preparation method of above material, comprises the following steps:

[0040] S1: Choose high purity (higher than 99.99%) Fe 2 o 3 and Y 2 o 3 As a raw material, Y was prepared by a solid-state reaction metho...

Embodiment 3

[0046] A non-reciprocal spin wave heterojunction waveguide material, which includes a GGG (gadolinium gallium garnet) single crystal substrate and a YIG / graphene heterojunction material, which is deposited on the GGG single crystal substrate by magnetron sputtering Growth high-quality YIG thin film, on YIG thin film, the monolayer graphene that gas phase deposition method is grown is transferred on the high-quality YIG thin film, drying treatment forms YIG / graphene heterojunction material, described YIG (yttrium iron pomegranate (Si) film is a monocrystalline film with a thickness of 1 micron. The single-layer graphene is grown by vapor deposition, and the area of the YIG / graphene heterojunction material is 5×5cm 2 .

[0047] The preparation method of above material, comprises the following steps:

[0048] S1: Choose high purity (higher than 99.99%) Fe 2 o 3 and Y 2 o 3 As a raw material, Y was prepared by a solid-state reaction method 3 Fe 5 o 12 The target materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com