Biochemical method for pre-treating coal gasification wastewater through denitrification

A coal gasification wastewater and denitrification technology, which is applied in chemical instruments and methods, multi-stage water treatment, natural water treatment, etc., can solve the problems of large investment, long hydraulic retention time, high operating cost, etc., to improve mass transfer rate, The effect of changing the structure of organic matter and improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

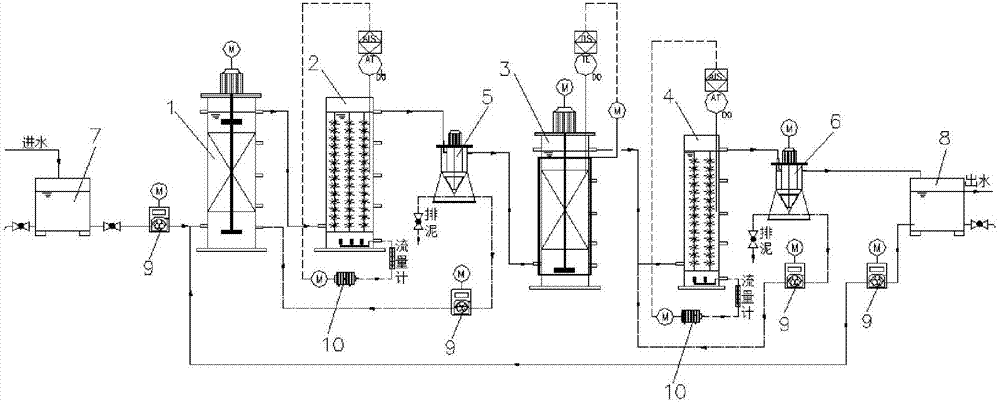

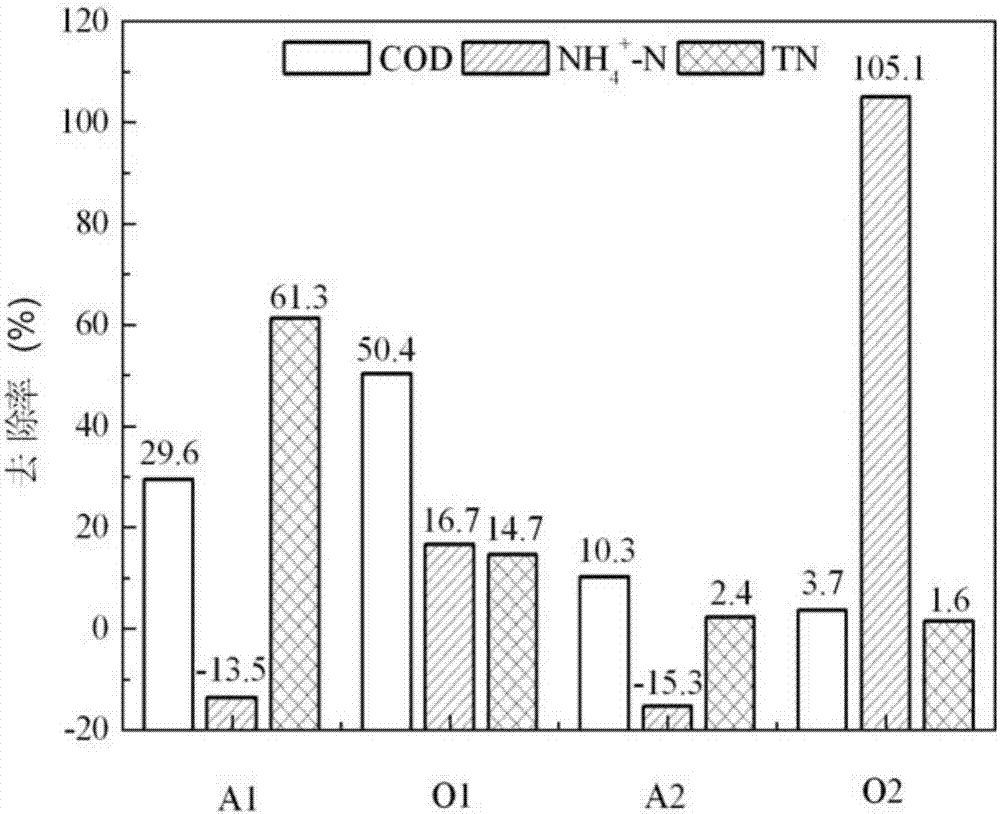

[0025] A new type of coal gasification wastewater treatment system in this embodiment includes anoxic denitrification tank (A1), aerobic decarbonization tank (O1), anaerobic hydrolysis tank (A2) and aerobic nitrification tank (O2) connected in sequence. ).

[0026] Among them, the effective reaction volume of the anoxic denitrification tank (A1) is 6L, and the HRT is 18h. It adopts the operation mode of biological fixed bed + stirring, and the upper and lower sides of the fixed bed inside the nitrification tank are respectively equipped with stirring blades.

[0027] The aerobic decarburization tank (O1) is filled with BF elastic filler, the filling ratio is 70%, the effective reaction volume is 8L, and the HRT is 24h; an online DO detection interlocking control aeration device is installed to maintain a low dissolved oxygen concentration in the tank (DO 0.5~ 1mg / L).

[0028] The design parameters of the intermediate settling tank and the secondary settling tank are the same,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com