Preparation method of carbon nano material-modified polymer

A technology of carbon nanomaterials and thermoplastic polymers, which is applied in the direction of single-component synthetic polymer rayon, rayon manufacturing, conductive/antistatic filament manufacturing, etc. It is easy to operate, improve physical and mechanical properties or electrical conductivity or thermal conductivity, and is suitable for large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Using a planetary ball mill, use a quartz ball with a diameter of 10mm as the large ball, and a quartz ball with a diameter of 6mm as the small ball. The mass ratio of the large ball to the small ball is 2:3. These two sizes of balls are used as grinding balls ;

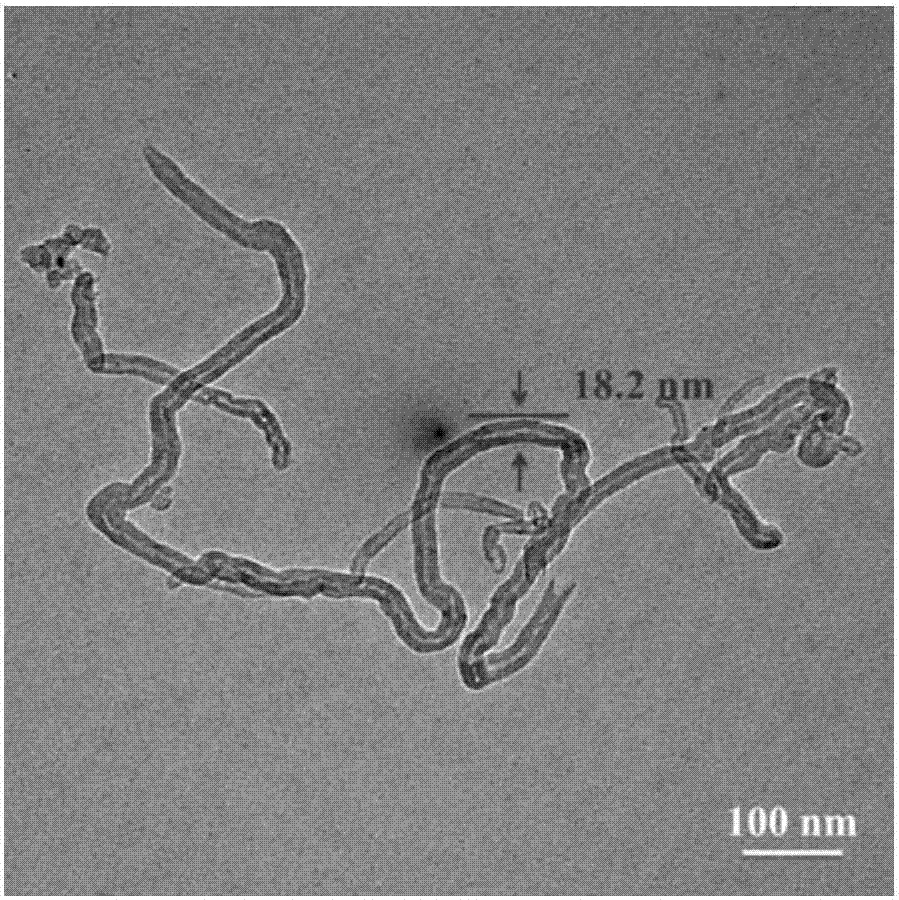

[0029] Add polyamide 6 and carboxylated carbon nanotubes (12 layers of walls, length 3 μm, 1% of the surface carbon atoms are carboxylated) into a planetary ball mill with a material-to-ball ratio of 1:2; ball mill for 3 hours at 100 rpm to obtain Raw materials, wherein the quality of carboxylated carbon nanotubes is 0.1% of the quality of polyamide 6;

[0030] 2) Melting and extruding the above raw materials with a single-screw extruder at 270°C, and winding the extruded product to obtain primary fibers;

[0031] 3) Secondary drafting of the above-mentioned as-spun fibers, the conditions are: thermal drafting 3 times, heat setting on a hot roller at 130° C. for 2 min to obtain carboxylated carbon nanotube...

Embodiment 2

[0039] 1) Using a roller ball mill, a zirconia ball with a diameter of 20 mm is used as a large ball, and a zirconia ball with a diameter of 5 mm is used as a small ball, and the mass ratio of the large ball to the small ball is 1:10. The ball is used as a grinding ball;

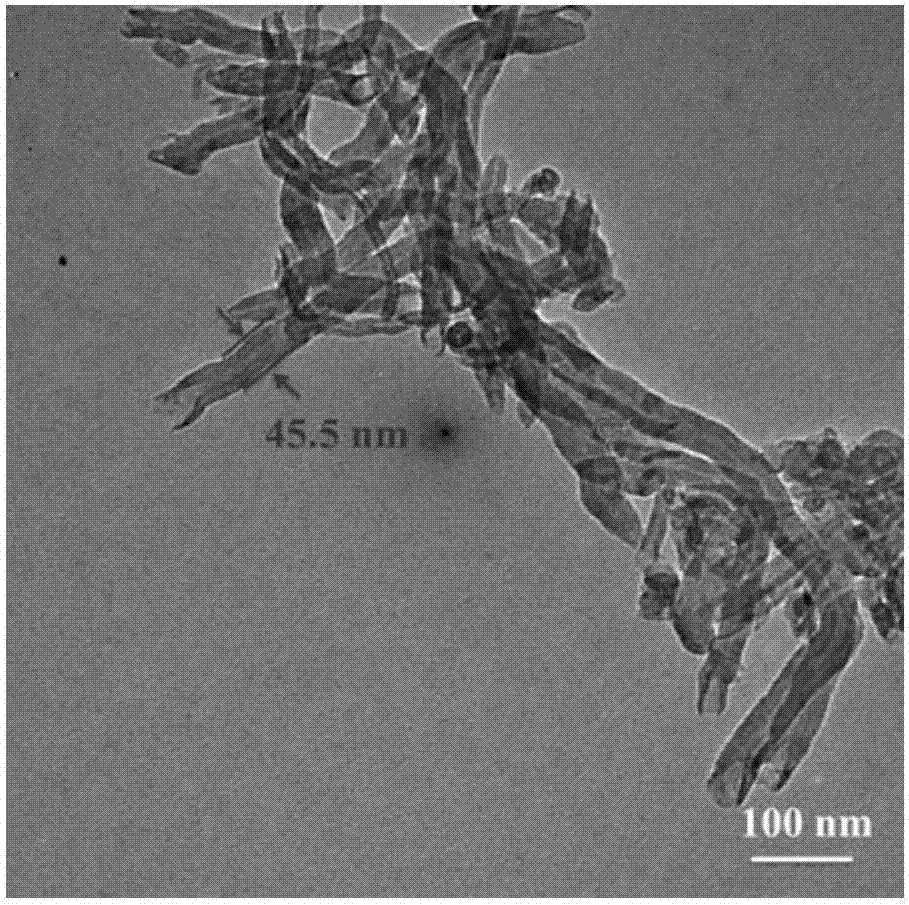

[0040] Add polyamide 66 and multi-walled carbon nanotubes (15 layers of walls, length 5 μm) into a roller ball mill with a material-to-ball ratio of 1:4; ball mill for 8 hours at 50 rpm to obtain raw materials, wherein the multi-walled carbon nanotubes The mass accounts for 0.8% of the mass of polyamide 66;

[0041] 2) Melting and extruding the above raw materials with a twin-screw extruder at 300°C, and winding the extruded product to obtain primary fibers;

[0042] 3) Perform secondary drafting on the above-mentioned as-spun fibers, the conditions are: hot drafting 3 times, heat setting on a hot roller at 130° C. for 2 min to obtain multi-walled carbon nanotube-reinforced polyamide 66 fibers.

[0043] Co...

Embodiment 3

[0045] 1) Using a drum-type ball mill, the alumina ball with a diameter of 14mm is used as the large ball, and the alumina ball with a diameter of 6mm is used as the small ball. The mass ratio of the large ball to the small ball is 1:6. The balls of these two sizes are used as grinding ball;

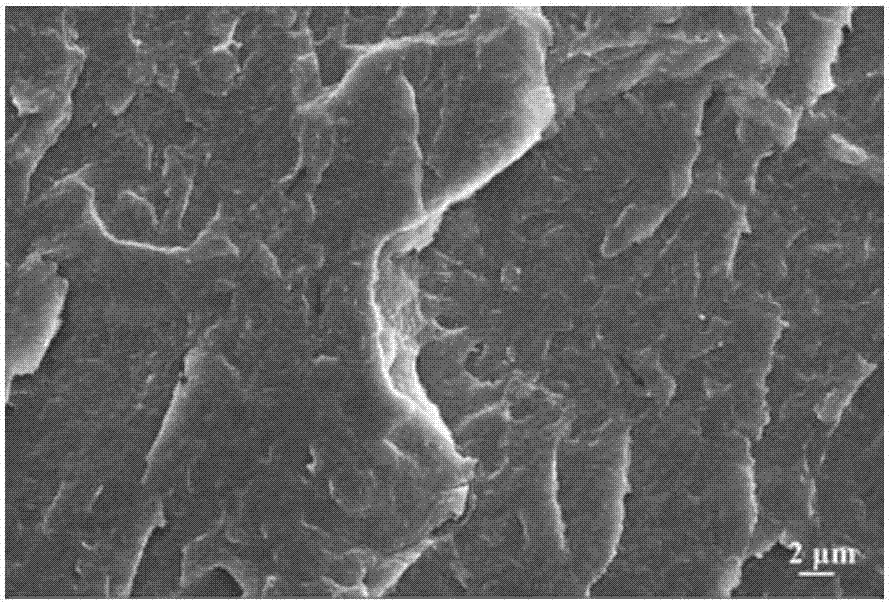

[0046] Add polyethylene terephthalate and graphene (1 to 5 layers, sheet diameter 3 μm) into a roller ball mill with a material-to-ball ratio of 1:4; ball mill for 5 hours at 300 rpm to obtain raw materials, in which graphene The mass accounts for 12% of the mass of polyethylene terephthalate;

[0047] 2) Melt and extrude the above raw materials at 300°C with a twin-screw extruder, heat-set on a hot roller at 130°C for 2 minutes after stretching 3.5 times hot to obtain polyethylene terephthalate / graphene conductive fiber.

[0048] The electrical conductivity of the polyethylene terephthalate / graphene conductive fiber is 2.3×10 2 S / cm, thermal conductivity is 0.42W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com