Preparation method of zinc telluride single crystal

A zinc telluride single crystal technology, which is applied in the field of II-VI semiconductor material preparation, can solve problems such as poor quality of zinc telluride single crystals, and achieve the effects of saving economic costs, reducing dosage, and good stoichiometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1. Clean the oil stains on the two quartz crucibles, and soak the quartz crucibles in analytical pure acetone for 24 hours; soak the quartz crucibles in a solution with a volume ratio of concentrated hydrochloric acid and concentrated nitric acid for 24 hours; soak the quartz crucibles in After immersing in 10% hydrofluoric acid solution for 30 minutes, take out the quartz crucible, wash it with deionized water, and dry it at 100°C.

[0023] Step 2: Put zinc and tellurium elemental raw materials with a purity of 99.9999% into the treated first quartz crucible at a molar ratio of 1:1. -5 At Pa, a polycrystalline material is synthesized.

[0024] Step 3: putting the cleaned second quartz crucible into a tube furnace, and attaching a layer of graphitic carbon film to the inner wall of the quartz crucible by thermally decomposing acetone.

[0025] Step 4. Put the materials into the second quartz crucible in the order of tellurium element and zinc telluride polycrystal...

Embodiment 2

[0031] Step 1. Clean the oil stains on the two quartz crucibles, and soak the quartz crucibles in analytical pure acetone for 24 hours; soak the quartz crucibles in a solution with a volume ratio of concentrated hydrochloric acid and concentrated nitric acid for 24 hours; soak the quartz crucibles in After immersing in 10% hydrofluoric acid solution for 30 minutes, take out the quartz crucible, wash it with deionized water, and dry it at 100°C.

[0032] Step 2: Put zinc and tellurium elemental raw materials with a purity of 99.9999% into the treated first quartz crucible at a molar ratio of 1:1. -5 Melt seal at Pa to synthesize polycrystalline material.

[0033] Step 3: putting the cleaned second quartz crucible into a tube furnace, and attaching a layer of graphitic carbon film to the inner wall of the quartz crucible by thermally decomposing acetone.

[0034] Step 4. Put the materials into the second quartz crucible in the order of tellurium element and zinc telluride polycry...

Embodiment 3

[0040] Step 1. Clean the oil stains on the two quartz crucibles, and soak the quartz crucibles in analytical pure acetone for 24 hours; soak the quartz crucibles in a solution with a volume ratio of concentrated hydrochloric acid and concentrated nitric acid for 24 hours; soak the quartz crucibles in After immersing in 10% hydrofluoric acid solution for 30 minutes, take out the quartz crucible, wash it with deionized water, and dry it at 100°C.

[0041] Step 2: Put zinc and tellurium elemental raw materials with a purity of 99.9999% into the treated first quartz crucible at a molar ratio of 1:1. -5 Melt seal at Pa to synthesize polycrystalline material.

[0042] Step 3: putting the cleaned second quartz crucible into a tube furnace, and attaching a layer of graphitic carbon film to the inner wall of the quartz crucible by thermally decomposing acetone.

[0043] Step 4. Put the materials into the second quartz crucible in the order of tellurium element and zinc telluride polyc...

PUM

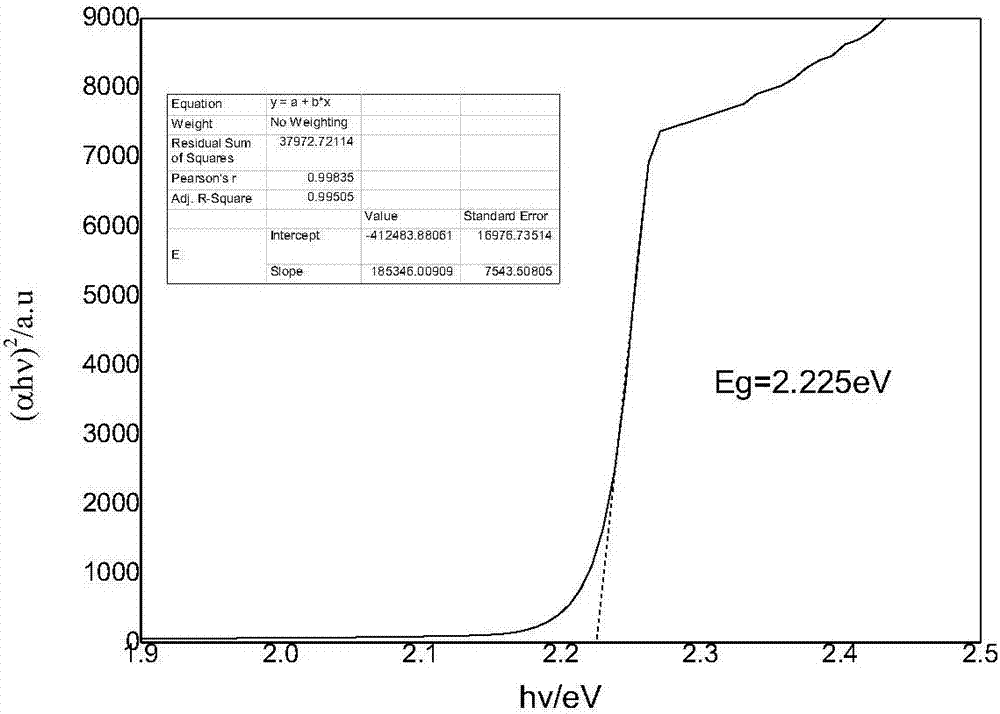

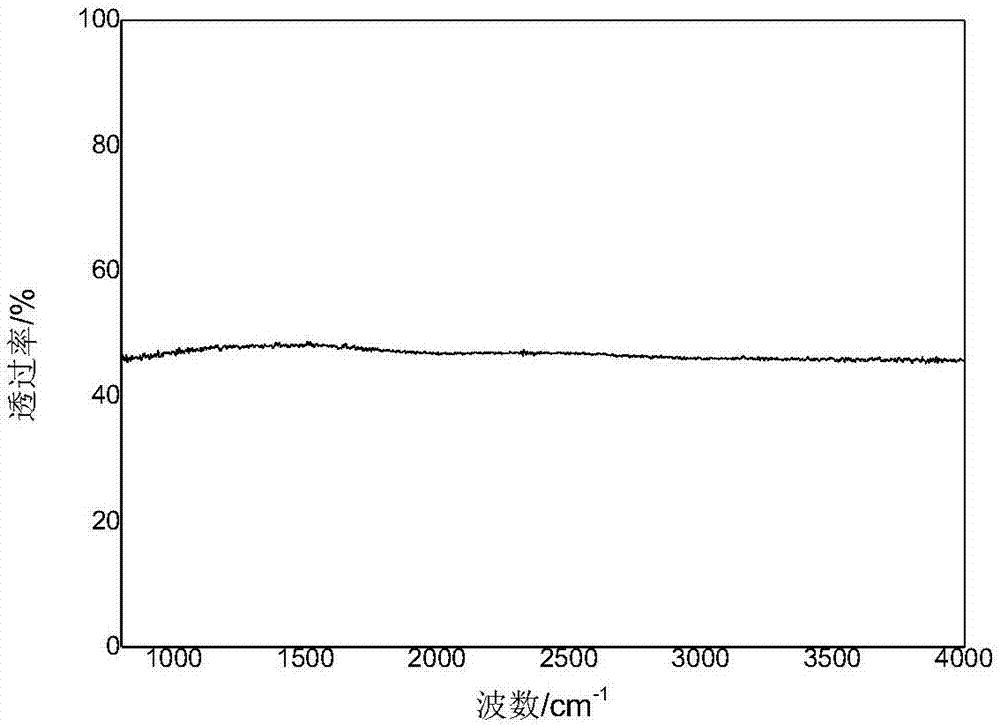

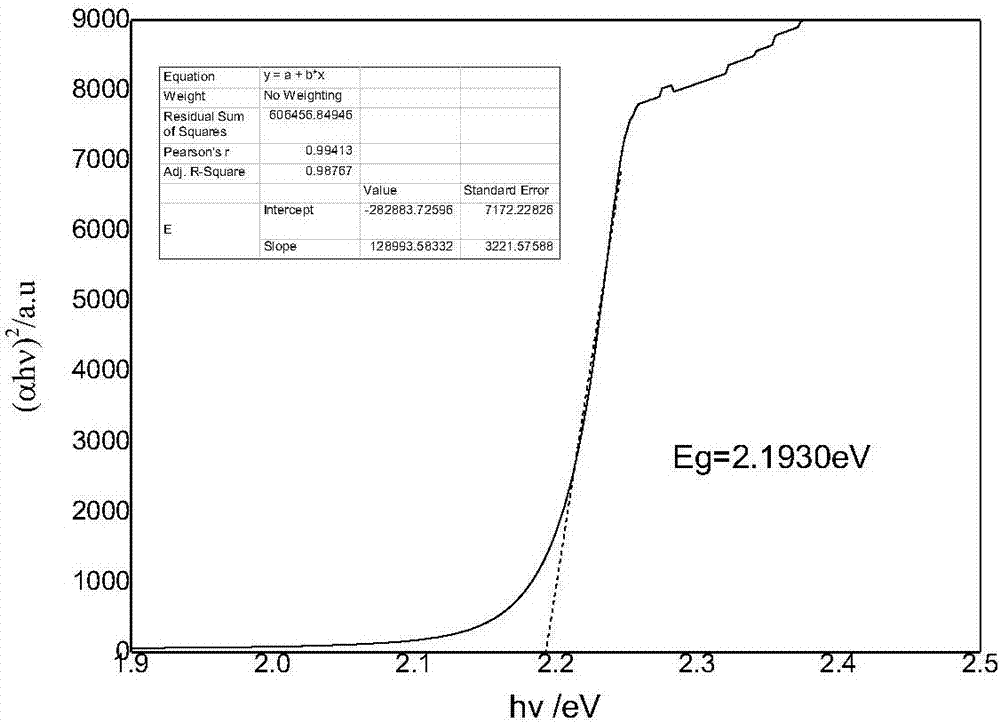

| Property | Measurement | Unit |

|---|---|---|

| infrared transmittance | aaaaa | aaaaa |

| infrared transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com