Device and method for measuring saturated vapor pressure

A technology of measuring device and measuring method, applied in the direction of measuring device, measuring fluid pressure, instrument, etc., can solve the problems of time waste, extremely high requirements for temperature and pressure measurement, long waiting time for temperature stabilization, etc., to save laboratory The effect of saving space, saving the cost of the test bench and saving the test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

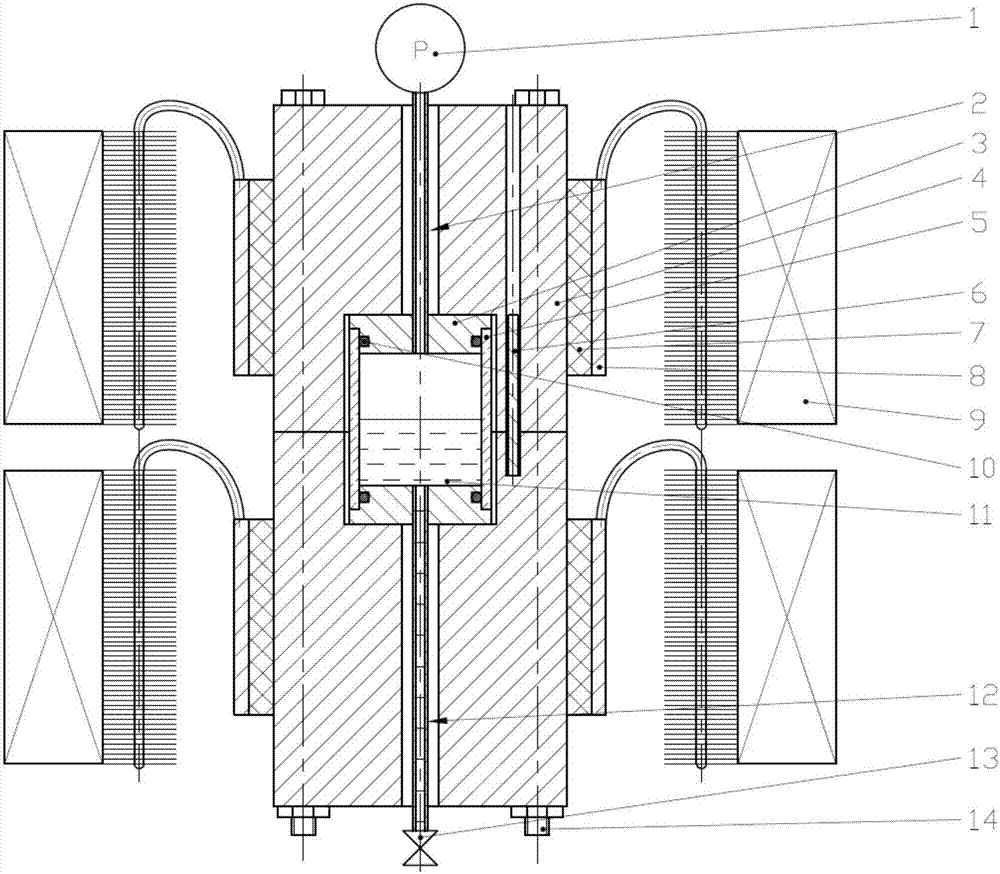

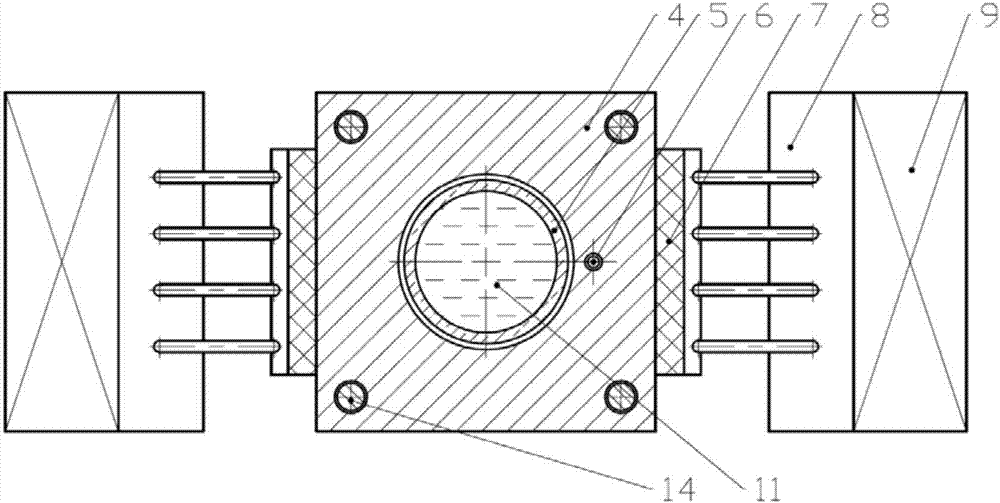

[0039] see figure 1 and figure 2 , the present invention includes a measurement body part and a temperature control part, wherein the measurement body part includes a quartz glass tube 5 for filling the fluid to be measured 11 and is vertically arranged, and the upper and lower ends of the quartz glass tube 5 are respectively provided with a The metal cover 3 sealed by the glass tube 5; the metal cover 3 at the upper end of the quartz glass tube 5 is provided with a pressure introduction tube 2 connected with the quartz glass tube 5, and the pressure introduction tube 2 and the metal cover 3 at the bottom thereof are welded to form an integral structure , the top of the pressure introduction tube 2 is higher than the top surface of the soaking metal block 4, and the top of the pressure introduction tube 2 is connected to the pressure sensor 1, and the pressure sensor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com