Method for extracting rice bran dietary fibers

A technology of dietary fiber and rice bran, which is applied in the field of food processing, can solve problems such as deep color of products, unsuitability for industrial production, and severe conditions, and achieve the effect of expanding resource utilization rate and comprehensive utilization value, eliminating equipment requirements, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

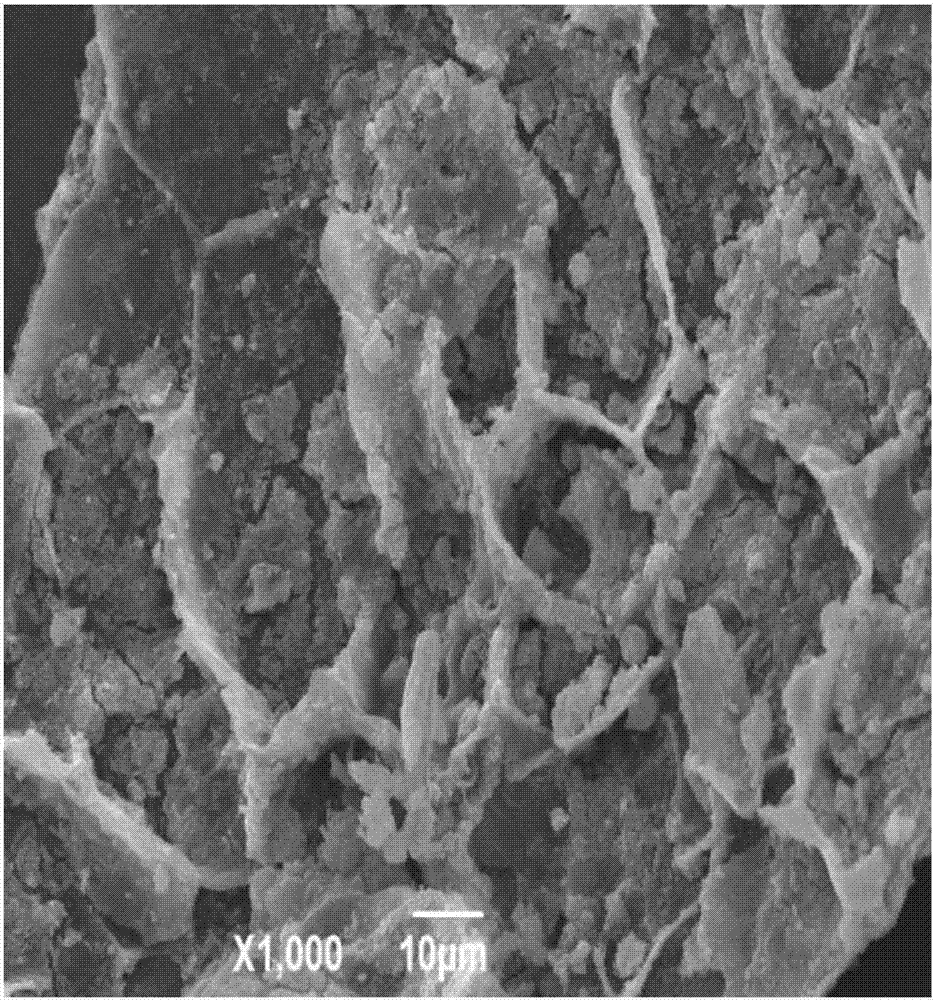

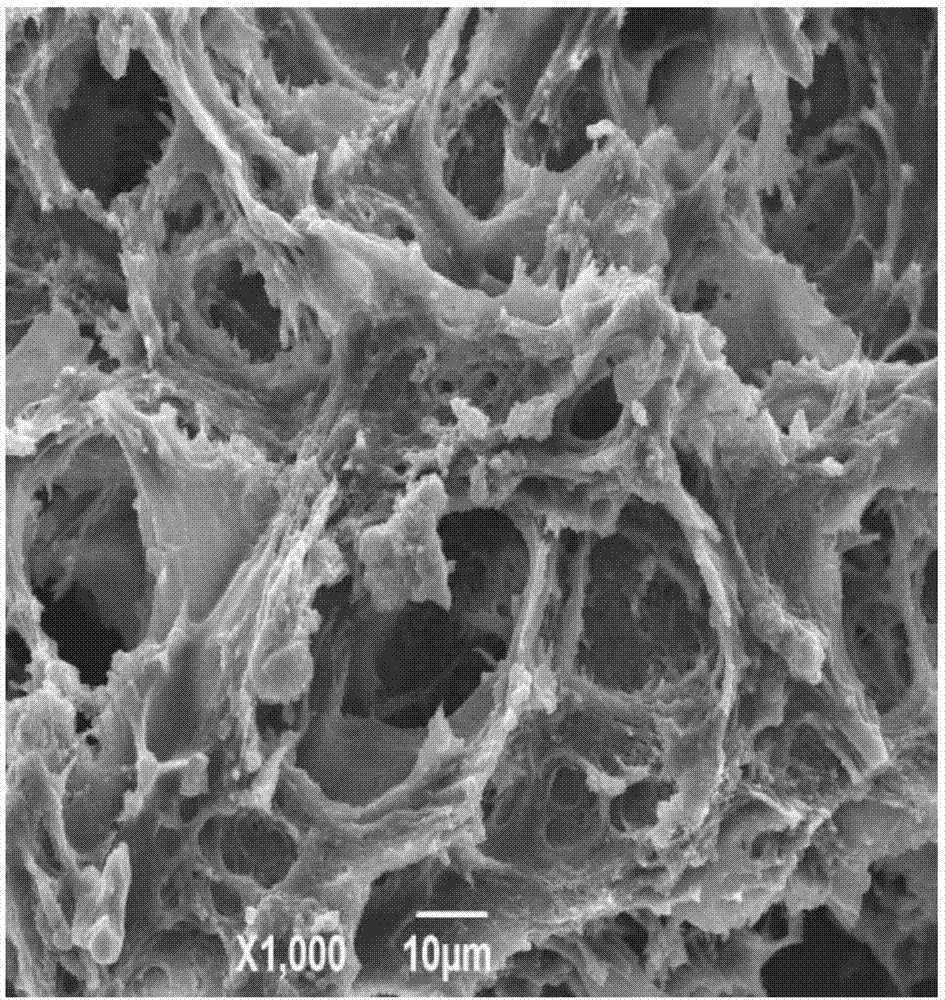

Image

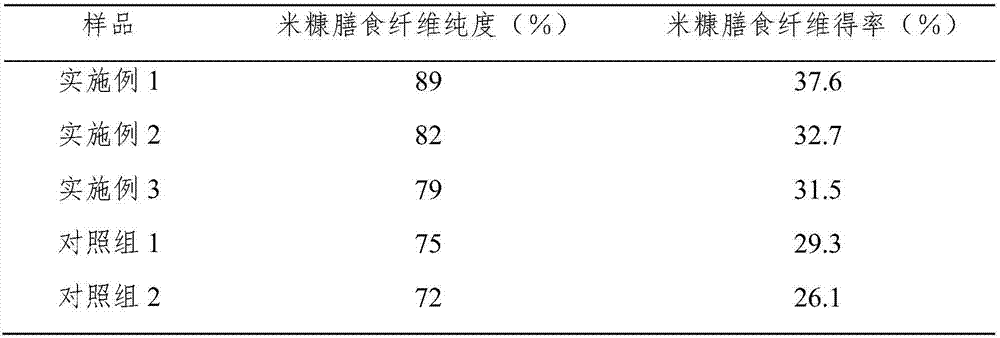

Examples

Embodiment 1

[0027] 1) Crushing and sieving: crushing the stabilized defatted rice bran, passing through a 40-mesh sieve to obtain pretreated rice bran for use.

[0028] 2) Enzymatic hydrolysis of starch: Accurately weigh 10g of pretreated rice bran, add 100mL of distilled water, adjust the pH to 5.5 with hydrochloric acid, add high-temperature-resistant amylase with an enzyme dosage of 2%, place it on a constant temperature water bath oscillator, and enzymatically hydrolyze at 75°C Shake for 3.5 hours, take it out, cool it down, and set it aside.

[0029] 3) Enzymatic hydrolysis of protein: adjust the pH to 8.2 with NaOH, add 2% protease, place on a constant temperature water bath shaker, shake at 60°C for a certain period of time for 2.5 hours, and inactivate the enzyme in a boiling water bath for 10 minutes.

[0030] 4) Centrifugation: 8000rmp, 10min. After centrifugation, the lower solid was lyophilized and collected to obtain insoluble dietary fiber (IDF).

[0031] 5) Sedimentation:...

Embodiment 2

[0034] 1) Crushing and sieving: crushing the stabilized defatted rice bran, passing through a 50-mesh sieve to obtain pretreated rice bran for use.

[0035] 2) Enzymatic hydrolysis of starch: Accurately weigh 10g of pretreated rice bran, add 100mL of distilled water, adjust the pH to 5 with hydrochloric acid, add high-temperature-resistant amylase with an enzyme dosage of 1%, place it on a constant temperature water bath oscillator, and enzymatically hydrolyze at 65°C Shake for 3 hours, take it out, cool it, and set it aside.

[0036] 3) Enzymatic hydrolysis of protein: adjust the pH to 8.0 with NaOH, add 0.5% protease, place on a constant temperature water bath shaker, shake at 50°C for a certain time for 2 hours, and inactivate the enzyme in a boiling water bath for 8 minutes.

[0037] 4) Centrifugation: 7000rmp, 12min. After centrifugation, the lower solid was lyophilized and collected to obtain insoluble dietary fiber (IDF).

[0038] 5) Settling: The supernatant after ce...

Embodiment 3

[0041] 1) Crushing and sieving: crushing the stabilized defatted rice bran, passing through a 60-mesh sieve to obtain pretreated rice bran for use.

[0042] 2) Enzymatic hydrolysis of starch: Accurately weigh 10g of pretreated rice bran, add 100mL of distilled water, adjust the pH to 6 with hydrochloric acid, add high-temperature-resistant amylase with an enzyme dosage of 3%, place it on a constant temperature water bath oscillator, and enzymatically hydrolyze at 90°C Shake for 4 hours, take it out, cool it down, and set it aside.

[0043] 3) Enzymatic hydrolysis of protein: adjust the pH to 8.5 with NaOH, add 1% protease in the amount of enzyme, place on a constant temperature water bath shaker, shake at 65°C for a certain time for 3 hours, and inactivate the enzyme in a boiling water bath for 9 minutes.

[0044] 4) Centrifugation: 9000rmp, 8min. After centrifugation, the lower solid was lyophilized and collected to obtain insoluble dietary fiber (IDF).

[0045] 5) Settling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com