Tetracobalt trisulfide nanometer hollow tube@foam nickel composite array material and preparation method and application thereof

A nano-composite array technology of tetracobalt trisulfide, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as unfavorable large-scale production, limited reserves of Pt group precious metals, and high price , to achieve good electrocatalytic activity for hydrogen evolution reaction, rich sources of raw materials, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

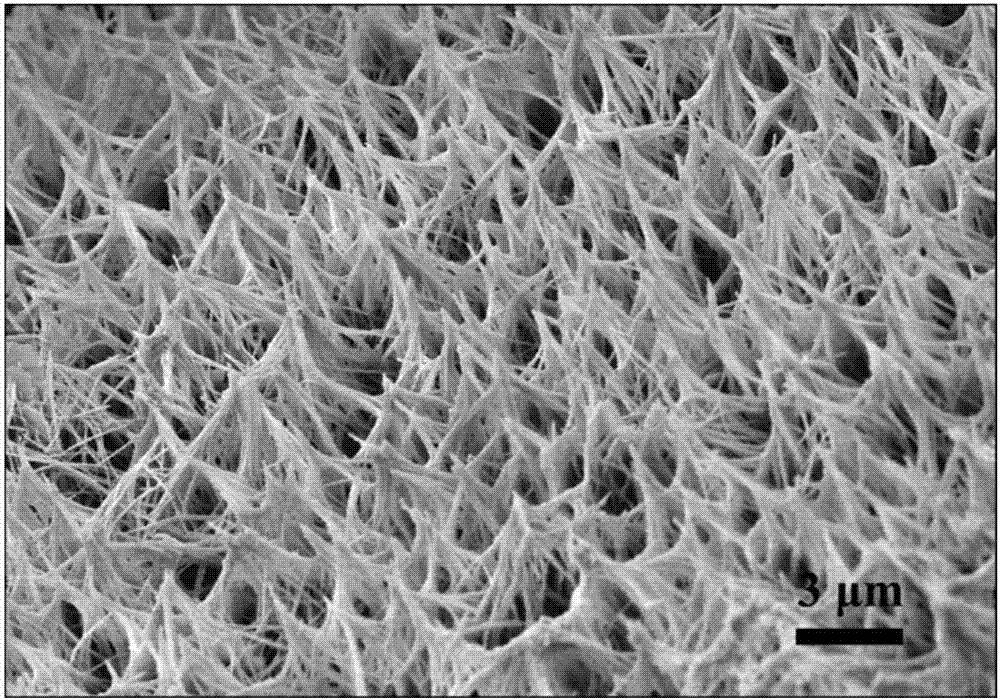

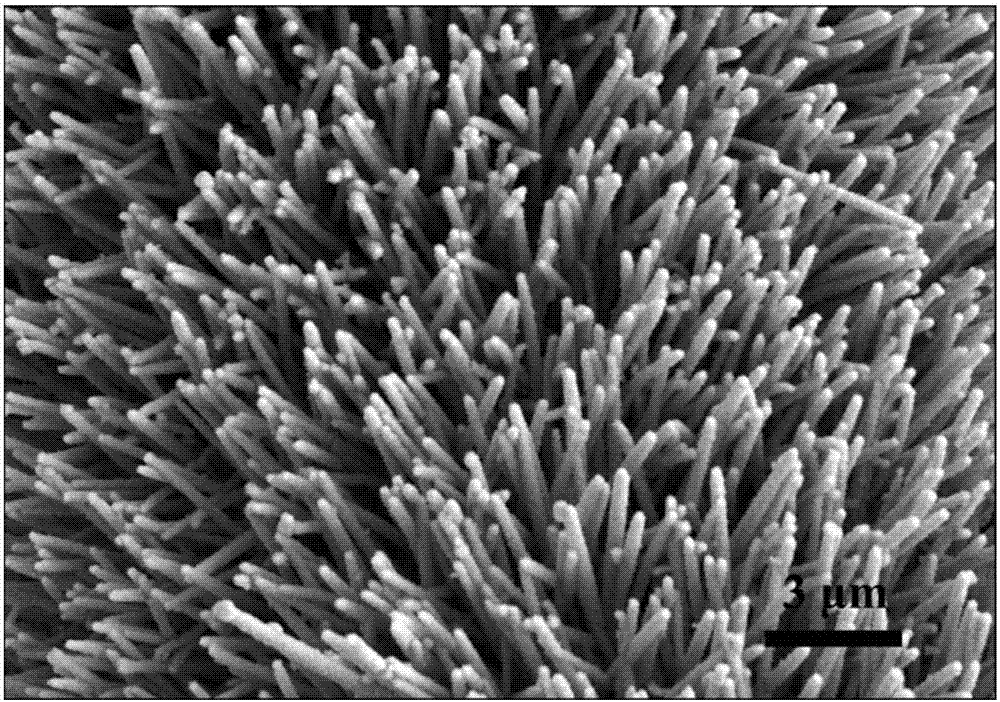

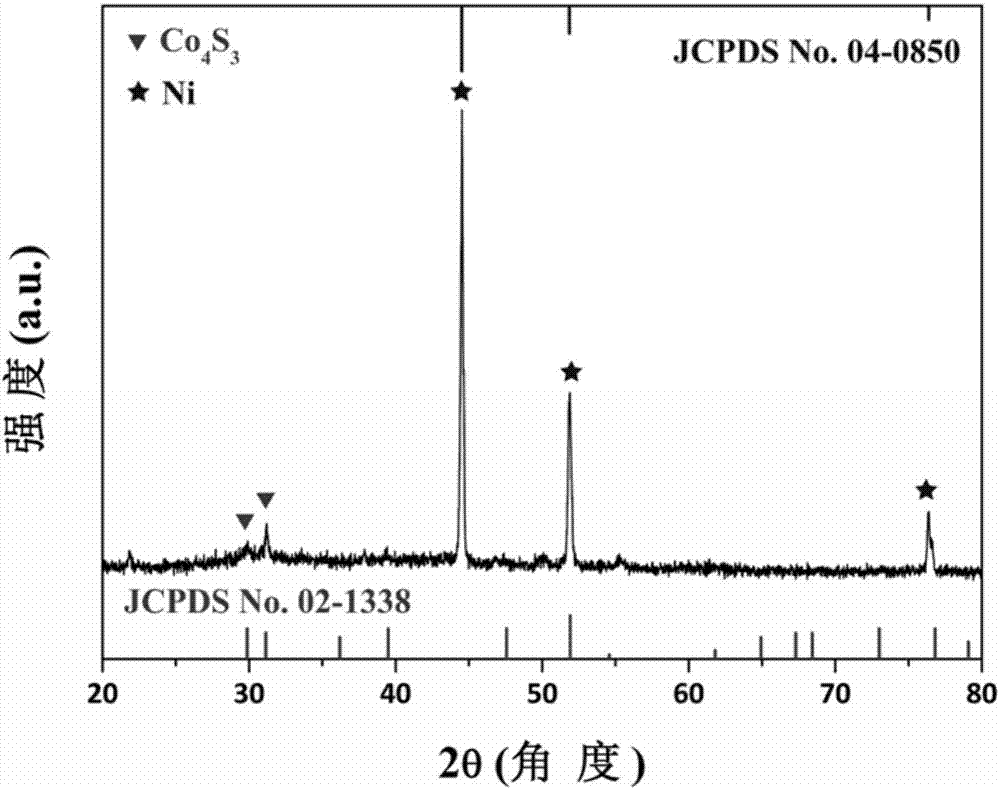

[0041] A preparation method of tetracobalt trisulfide nano hollow tube@foamed nickel composite array material, comprising the following steps:

[0042] (1) The nickel foam with a size of 1cm × 4cm was subjected to surface degreasing and degreasing treatment in acetone, then washed with hydrochloric acid solution to remove surface oxides, and then washed the surface with ethanol and ultrapure water, and then vacuum-dried.

[0043] (2) cobalt chloride hexahydrate, urea are added in 30ml deionized water with the ratio of 2mmol:10mmol, stir to dissolve rapidly, obtain uniform solution A, solution A is transferred in the reactor of polytetrafluoroethylene lining, The nickel foam obtained in the step (1) was placed in it, the reaction kettle was closed, put into a blast drying oven, and heated at 90° C. for 8h;

[0044] (3) Take out the nickel foam after the reaction in step (2), put it into a vacuum drying oven, and dry it at 60° C. for 6 hours to obtain a product of nickel foam su...

Embodiment 2

[0049] A preparation method of tetracobalt trisulfide nano hollow tube@foamed nickel composite array material, comprising the following steps:

[0050] (1) The nickel foam with a size of 1cm × 4cm was subjected to surface degreasing and degreasing treatment in acetone, and then washed with hydrochloric acid solution to remove surface oxides, and then the surface was washed with ethanol and ultrapure water, and then vacuum-dried.

[0051] (2) cobalt chloride hexahydrate, urea are added in 40ml deionized water with the ratio of 3mmol:15mmol, stir to dissolve rapidly, obtain homogeneous solution A, solution A is transferred in the reaction kettle of polytetrafluoroethylene lining, The nickel foam obtained in step (1) was placed in it, the reaction kettle was closed, put into a blast drying oven, and heated at 100 ° C for 10 h;

[0052] (3) Take out the nickel foam after the reaction in step (2), put it into a vacuum drying oven, and dry it at 60° C. for 6 hours to obtain a produc...

Embodiment 3

[0057] A preparation method of tetracobalt trisulfide nano hollow tube@foamed nickel composite array material, comprising the following steps:

[0058] (1) The nickel foam with a size of 1cm × 4cm was subjected to surface degreasing and degreasing treatment in acetone, and then washed with hydrochloric acid solution to remove surface oxides, and then the surface was washed with ethanol and ultrapure water, and then vacuum-dried.

[0059] (2) cobalt chloride hexahydrate, urea are added in 35ml deionized water with the ratio of 2mmol:10mmol, stir to dissolve rapidly, obtain homogeneous solution A, solution A is transferred in the reactor of polytetrafluoroethylene lining, and place the nickel foam obtained in step (1) in it, close the reaction kettle, put it into a blast drying oven, and heat it at 95°C for 8h;

[0060] (3) Take out the nickel foam after the reaction in step (2), put it into a vacuum drying oven, and dry it at 60° C. for 6 hours to obtain a product of nickel foa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com