A method for manufacturing a quartz glass cylindrical polishing disc based on a gel substrate

A quartz glass, gel-based technology, used in grinding/polishing equipment, wheels with flexible working parts, manufacturing tools, etc., can solve problems such as toxicity, increased polishing costs, environmental pollution, etc., and achieve improved strength. and elasticity, saving polishing abrasives, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for manufacturing a quartz glass cylindrical polishing disc based on a gel substrate, the specific steps are:

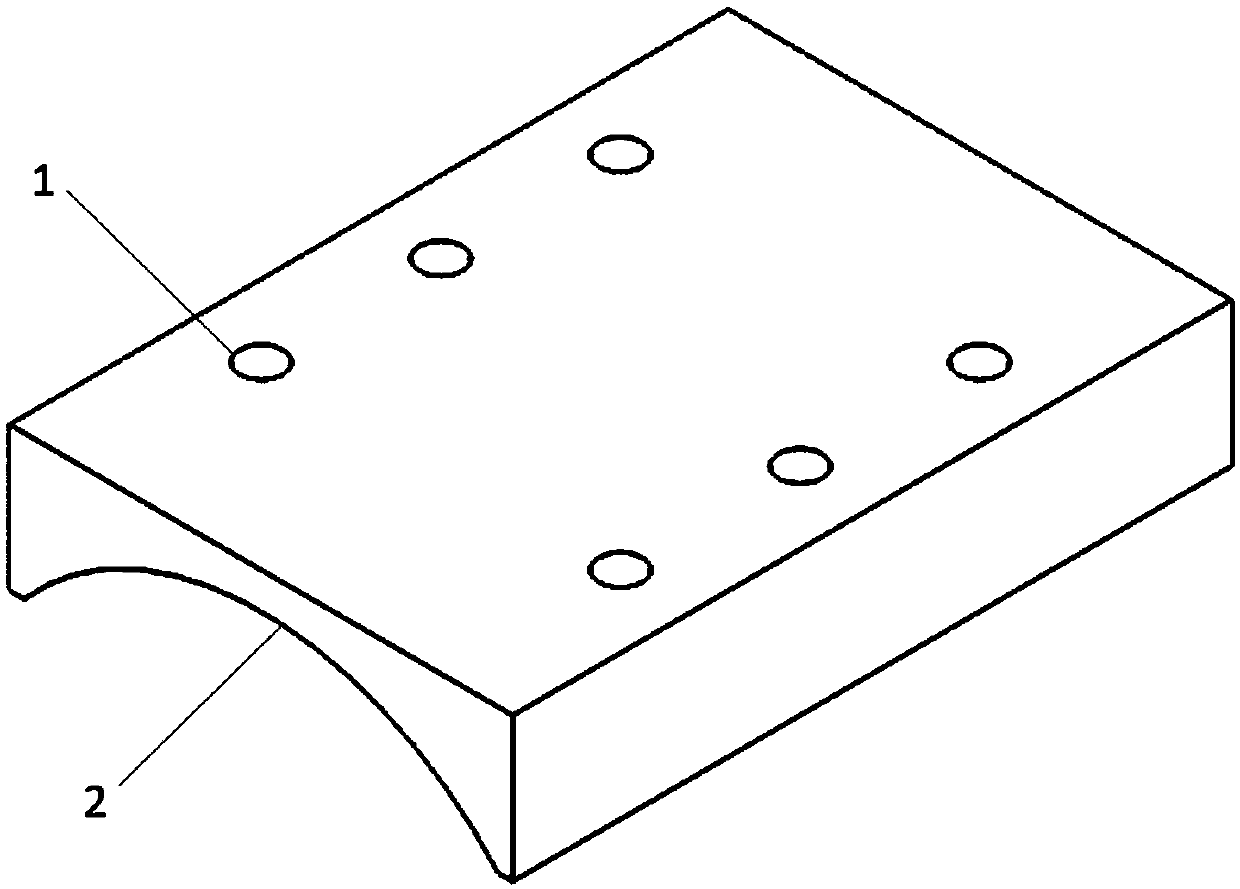

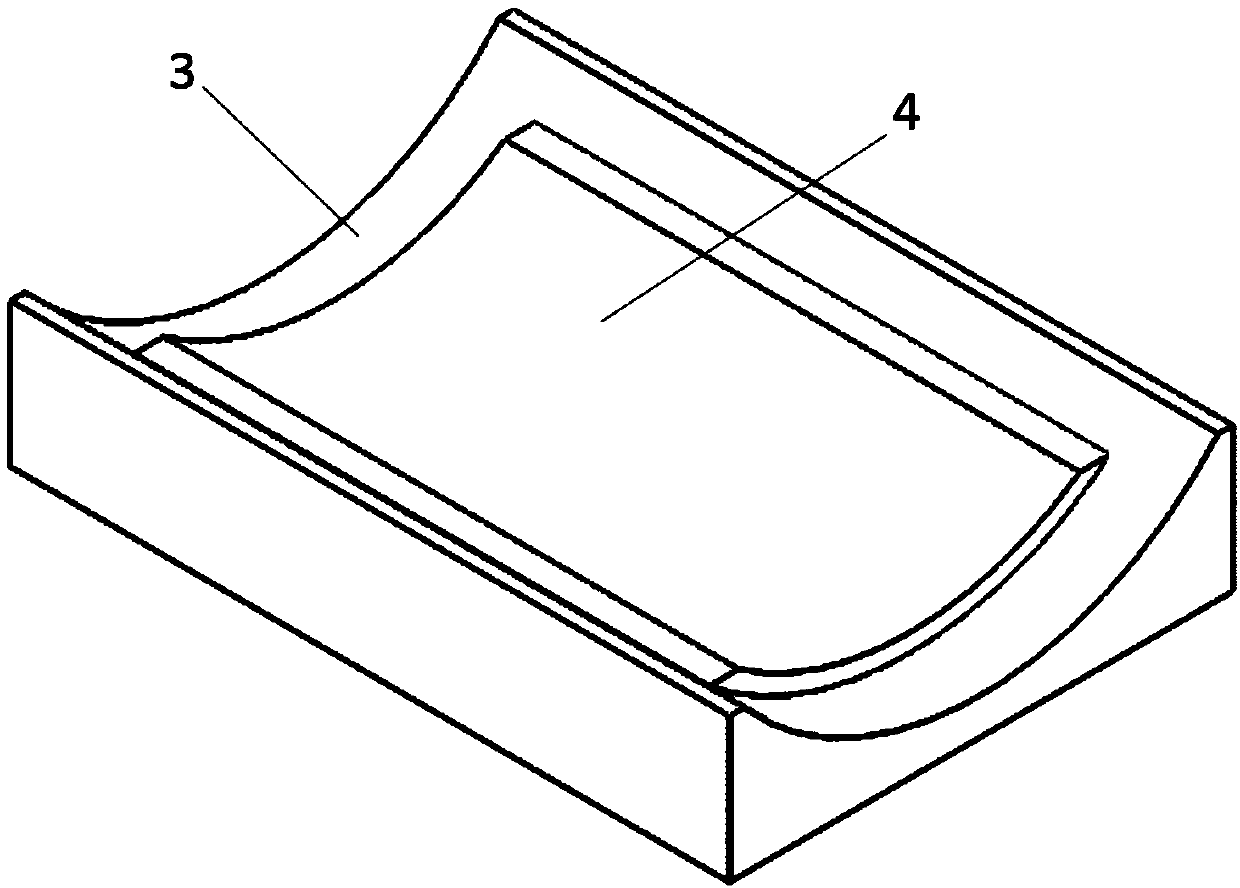

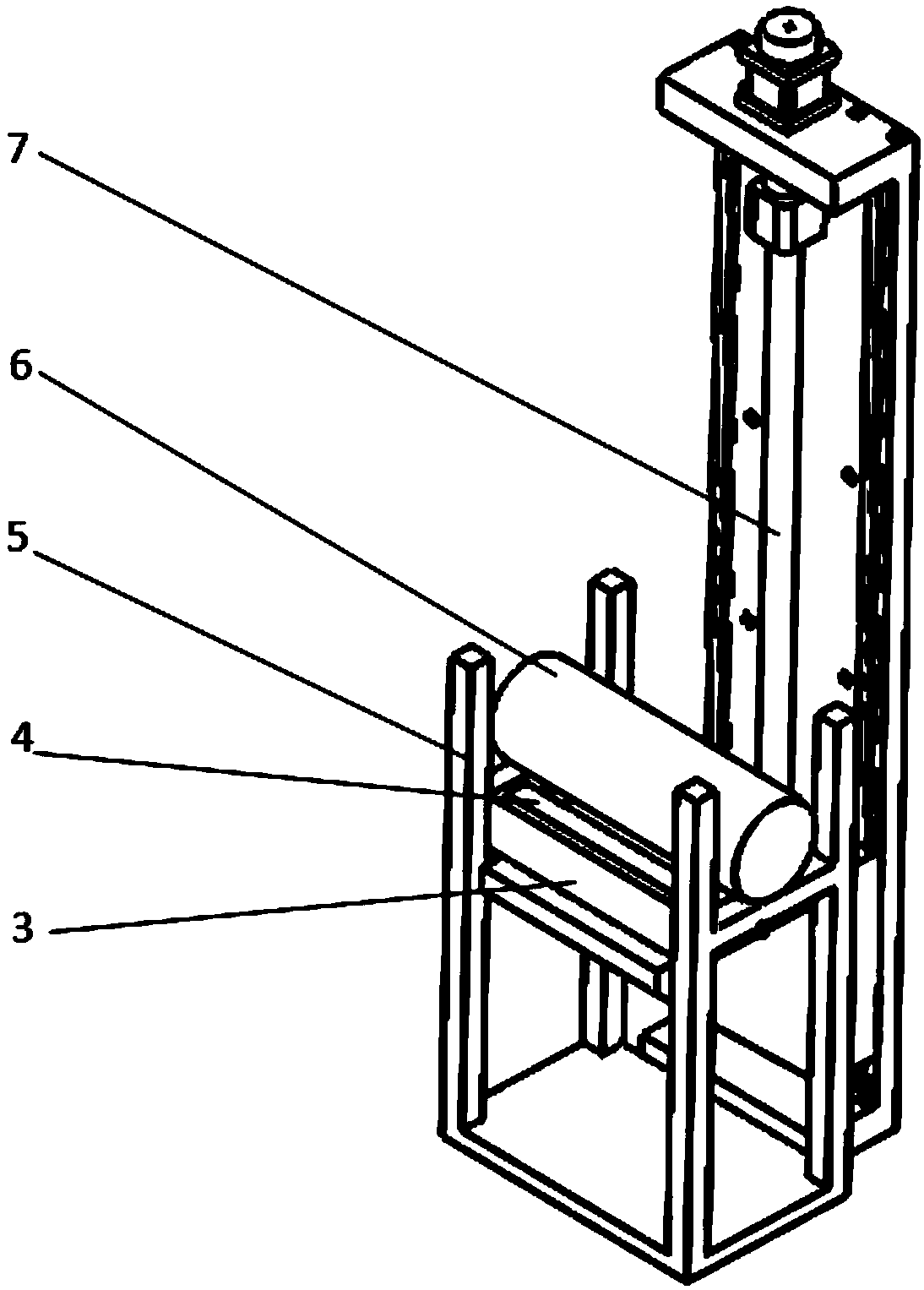

[0024] (1) Determine the mold size of the bearing gel base, according to the formula L=(r 1 -r 2 )*4.5, where L is the thickness of the gel base, r 1 is the radius of the mold carrying the gel base, r 2 is the actual radius of the quartz glass cylindrical surface to be polished, and the mold is a stainless steel mold, such as figure 1 The front of the mold 3 is provided with an arc-shaped groove bearing surface 2 for carrying the gel base, and the back is provided with bolt holes 1 for installation and connection.

[0025] (2) Preparation of gel samples: polyvinyl alcohol particles were placed in distilled water, heated and stirred in a water bath at 95°C for 6 hours to dissolve, and the water reduced by evaporation was continuously replenished, and finally a clear polyvinyl alcohol aqueous solution was prepared, and cooled to room temperature for ...

Embodiment 2

[0029] A method for manufacturing a quartz glass cylindrical polishing disc based on a gel substrate, the specific steps are:

[0030] (1) Determine the mold size of the bearing gel base, according to the formula L=(r 1 -r 2 )*4.5, where L is the thickness of the gel base, r 1 is the radius of the mold carrying the gel base, r 2 is the actual radius of the quartz glass cylindrical surface to be polished, and the mold is a stainless steel mold, such as figure 1 The front of the mold 3 is provided with an arc-shaped groove bearing surface 2 for carrying the gel base, and the back is provided with bolt holes 1 for installation and connection.

[0031] (2) Preparation of gel samples: polyvinyl alcohol particles were placed in distilled water, heated and stirred in a water bath at 95°C for 6 hours to dissolve, and the water reduced by evaporation was continuously replenished, and finally a clear polyvinyl alcohol aqueous solution was prepared, and cooled to room temperature for ...

Embodiment 3

[0035] A method for manufacturing a quartz glass cylindrical polishing disc based on a gel substrate, the specific steps are:

[0036] (1) Determine the mold size of the bearing gel base, according to the formula L=(r 1 -r 2 )*4.5, where L is the thickness of the gel base, r 1 is the radius of the mold carrying the gel base, r 2 is the actual radius of the quartz glass cylinder to be polished, and the mold is a stainless steel mold, such as figure 1 The front of the mold 3 is provided with an arc-shaped groove bearing surface 2 for carrying the gel base, and the back is provided with bolt holes 1 for installation and connection.

[0037](2) Preparation of gel samples: polyvinyl alcohol particles were placed in distilled water, heated and stirred in a water bath at 95°C for 6 hours to dissolve, and the water reduced by evaporation was continuously replenished, and finally a clear polyvinyl alcohol aqueous solution was prepared, and cooled to room temperature for later use. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com