Preparation method of nano structured cubic indium oxide gas sensitive material

A nanostructure and cube technology, applied in the field of preparation of cubic nanostructure indium oxide gas-sensing materials, can solve problems such as not very deep exploration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Weigh a certain amount of indium trichloride tetrahydrate and 1,4-butanediamine, and dissolve them in 40 mL of deionized water, in which the concentration of indium trichloride tetrahydrate is 0.025 mol / L, 1,4- The concentration of butanediamine is 0.025 mol / L, and the molar ratio of indium trichloride tetrahydrate and 1,4-butanediamine is controlled to be 1:1;

[0017] (2) Move the mixed solution obtained in step (1) to a hydrothermal reaction kettle lined with polytetrafluoroethylene, conduct a hydrothermal reaction at a temperature of 180 °C for 8 h, and then use the product after the hydrothermal reaction The centrifuge is used for solid-liquid separation, and the obtained solid product is washed several times with deionized water and ethanol;

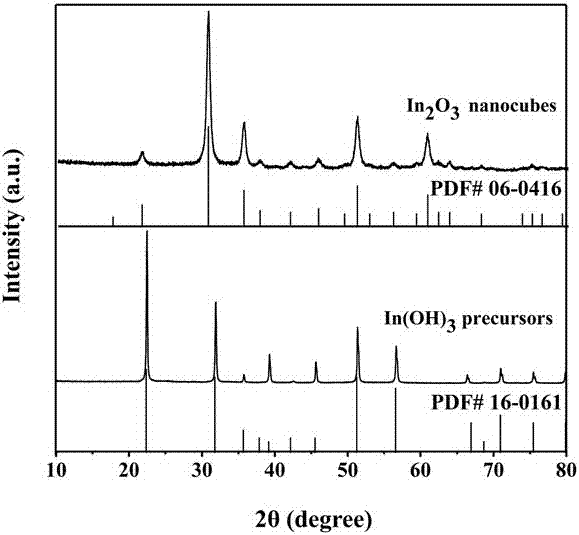

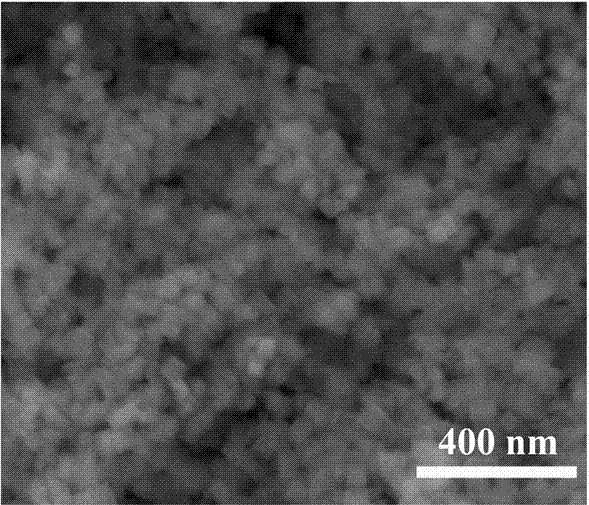

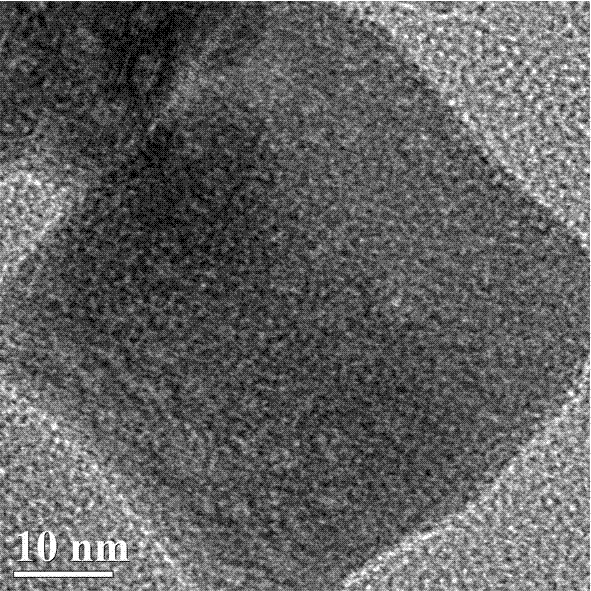

[0018] (3) Place the solid product obtained in step (2) in a drying oven, dry it at 60 °C, put it in an alumina crucible and put it in a muffle furnace, and heat it at 500 °C for 3 h to obtain cubic indium oxide powder w...

Embodiment 2

[0020] (1) Weigh a certain amount of indium trichloride tetrahydrate and 1,4-butanediamine, and dissolve them in 40 mL of deionized water, in which the concentration of indium trichloride tetrahydrate is 0.025 mol / L, 1,4- The concentration of butanediamine is 0.025 mol / L, and the molar ratio of indium trichloride tetrahydrate and 1,4-butanediamine is controlled to be 1:1;

[0021] (2) Move the mixed solution obtained in step (1) to a hydrothermal reaction kettle lined with polytetrafluoroethylene, conduct a hydrothermal reaction at 180 °C for 12 h, and then use the hydrothermal reaction product The centrifuge is used for solid-liquid separation, and the obtained solid product is washed several times with deionized water and ethanol;

[0022] (3) Place the solid product obtained in step (2) in a drying oven, dry it at 60 °C, put it in an alumina crucible and put it in a muffle furnace, and heat it at 500 °C for 3 h to obtain cubic indium oxide powder with a porous structure bo...

Embodiment 3

[0024] (1) Weigh a certain amount of indium trichloride tetrahydrate and 1,4-butanediamine, and dissolve them in 40 mL of deionized water, in which the concentration of indium trichloride tetrahydrate is 0.025 mol / L, 1,4- The concentration of butanediamine is 0.025 mol / L, and the molar ratio of indium trichloride tetrahydrate and 1,4-butanediamine is controlled to be 1:1;

[0025] (2) Move the mixed solution obtained in step (1) to a hydrothermal reaction kettle lined with polytetrafluoroethylene, conduct a hydrothermal reaction at a temperature of 180 °C for 20 h, and then use the product after the hydrothermal reaction The centrifuge is used for solid-liquid separation, and the obtained solid product is washed several times with deionized water and ethanol;

[0026] (3) Place the solid product obtained in step (2) in a drying oven, dry it at 60 °C, put it in an alumina crucible and put it in a muffle furnace, and heat it at 500 °C for 3 h to obtain cubic indium oxide powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com