A kind of sliding plate for bridge support and its preparation method

A technology of bridge bearings and slide plates, applied in the direction of coating, etc., can solve the problems that the compressive stress cannot be higher than 45MPa and the pressure bearing capacity is not high, and achieve the effects of good wear resistance, improved bearing capacity and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

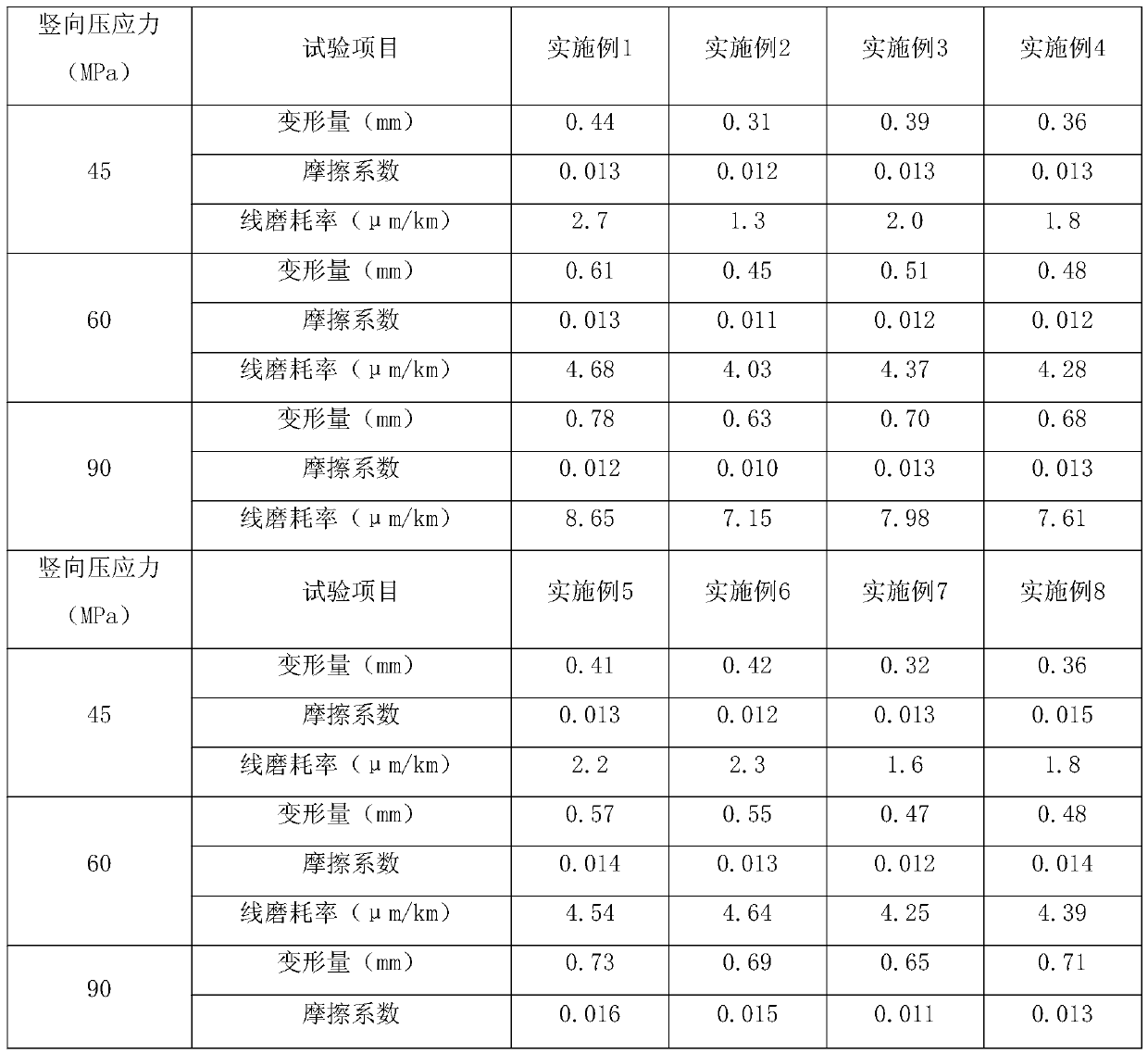

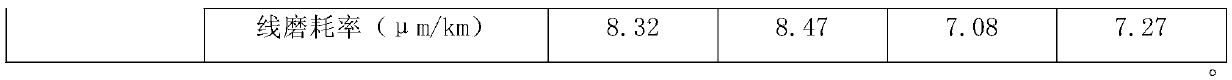

Examples

preparation example Construction

[0038] The present invention also provides a preparation process for the above-mentioned modified material, which mainly includes the following steps:

[0039] (1) Raw material preparation: dry resins such as polyphenylene sulfide and polytetrafluoroethylene at 105°C for 2 hours for later use;

[0040] (2) Activation treatment: surface-treat the reinforcing fibers, molybdenum disulfide, etc. with a coupling agent, dry at 110°C for 2 hours, and then pulverize for later use;

[0041] (3) Preparation of mixture: put the resin matrix, friction performance modifier, and reinforcement system into a high-speed mixer according to a certain mass ratio for high-speed mixing to obtain the mixture;

[0042] (4) Extrusion granulation: Add the mixture prepared in step (3) into the twin-screw extruder for extrusion granulation; the heating temperature setting range of each section of the extruder is 270 ° C ~ 310 ° C The temperature gradually rises from the hopper to the die; the strips at ...

Embodiment 1

[0046] For the preparation of the material of the present invention, each material is compounded according to the following weight ratio: 85% polyphenylene sulfide, 4% polytetrafluoroethylene micropowder, 1% molybdenum disulfide, 9% carbon fiber, 1% graphene;

[0047]First use 1% silane coupling agent KH550 of carbon fiber to carry out surface treatment to carbon fiber, use 1% silane coupling agent KH550 of molybdenum disulfide to carry out surface treatment to molybdenum disulfide, then, polyphenylene sulfide, poly Tetrafluoroethylene and surface-activated carbon fibers and molybdenum disulfide were placed in a vacuum oven at 110°C for 2 hours to dry; the carbon fibers were pulverized and mixed with polyphenylene sulfide, polytetrafluoroethylene, molybdenum disulfide, graphene, etc. Stir and disperse at high speed in a high-speed mixer. The mixed and dispersed mixture is introduced into the hopper of the extruder, and the heating temperature of each section of the extruder is...

Embodiment 2

[0049] For the preparation of the material of the present invention, each material is prepared according to the following weight ratio: 40% polyphenylene sulfide, 16% polytetrafluoroethylene micropowder, 4% molybdenum disulfide, 36% carbon fiber, 4% graphene;

[0050] First use 2% silane coupling agent KH550 of carbon fiber weight ratio to carry out surface treatment to carbon fiber, use 2% molybdenum disulfide weight ratio silane coupling agent KH550 to carry out surface treatment to molybdenum disulfide, then polyphenylene sulfide, Polytetrafluoroethylene and surface-activated carbon fibers and molybdenum disulfide were placed in a vacuum oven at 130°C for 2 hours to dry; Stir and disperse at high speed in a high-speed mixer. The mixed and dispersed mixture is introduced into the hopper of the extruder, and the heating temperature of each section of the extruder is set between 270°C and 310°C, and the extrusion granulation is carried out after the temperature of each section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com