An ultra-thin nano-type anti-corrosion coating and its self-leveling dip-coating process

An anti-corrosion coating and nano-technology, applied in the field of coating anti-corrosion, can solve the problems of demanding aluminum phosphate particles, inability to achieve dip coating, complex production process, etc., to achieve enhanced physical isolation, good anti-corrosion performance, wear resistance and scratch resistance. High performance and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

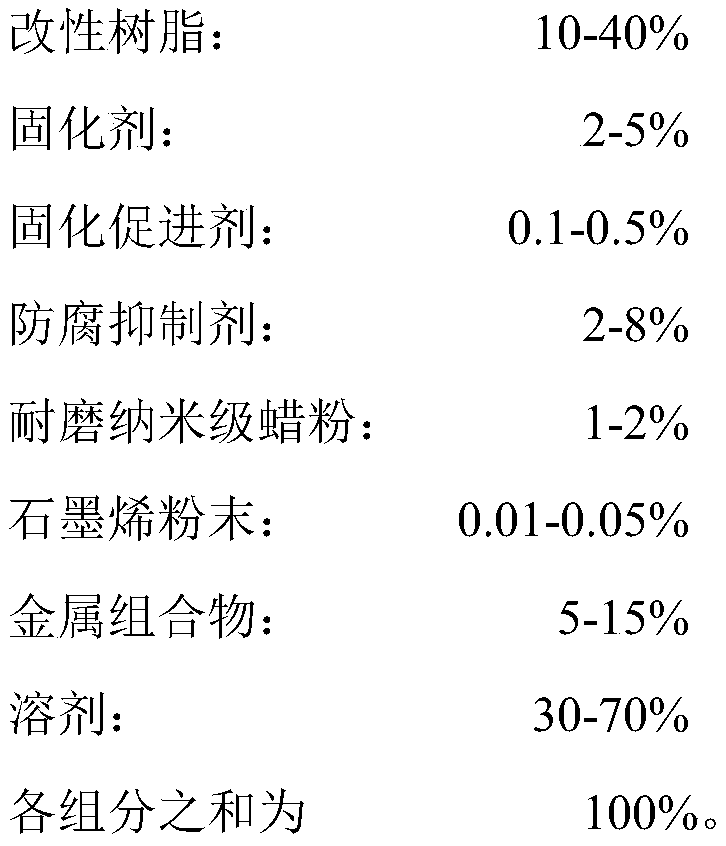

[0025] A kind of ultra-thin nano-type anticorrosion coating provided by the invention comprises the following components by weight percentage:

[0026]

[0027] The modified resin is a hydroxyl-terminated polydimethylsiloxane modified epoxy resin with an epoxy equivalent of 430 and a viscosity of 12000 cps;

[0028] The solvent is formed by mixing cyclohexane and ethanol at a volume ratio of 7:5.

[0029] The anticorrosion inhibitor is prepared by the following method: Weigh the following components by weight: 40 parts of ethanol, 0.5 parts of phosphoric acid, 1 part of polyethylene glycol, 2 parts of aluminate coupling agent, solvent-based nanometer Add 25 parts of silicon oxide dispersion liquid, 15 parts of aluminum tripolysilicate, and 12 parts of zinc phosphate into the reaction kettle, stir evenly at a high speed at room temperature, then raise the temperature to 80°C, add 3 parts of hexamethylenetetramine and 1 part of cyclic The mixed solution of hexylamine was add...

Embodiment 2

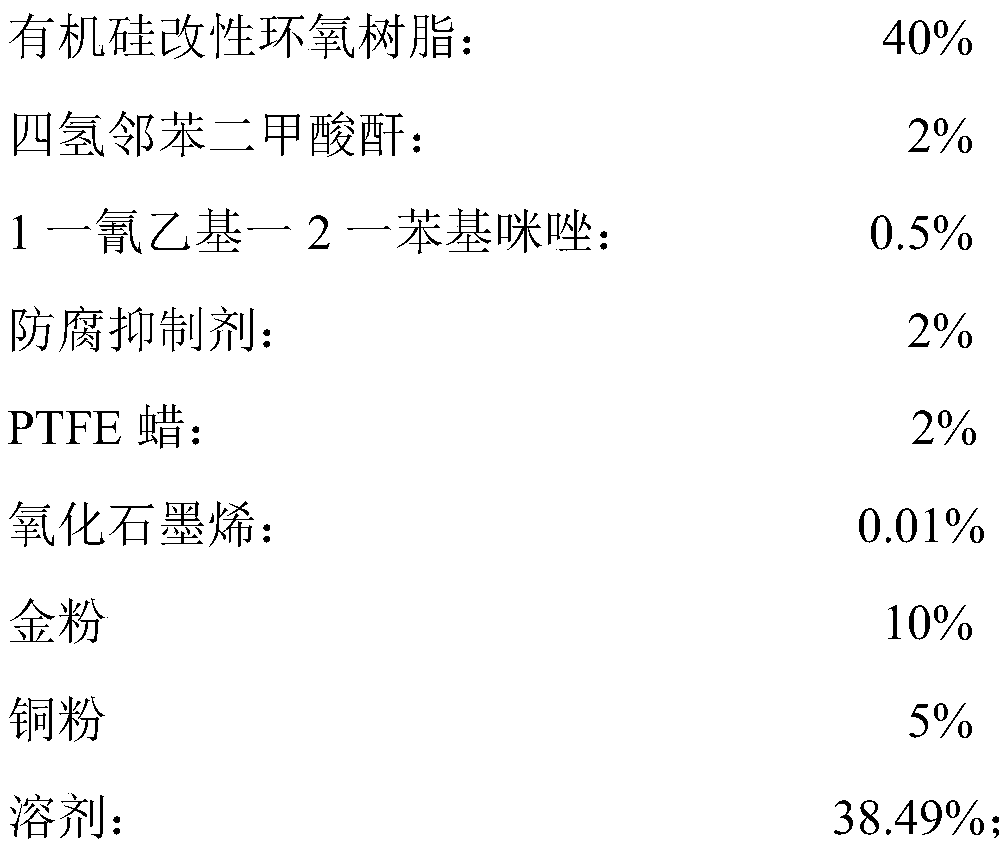

[0031] A kind of ultra-thin nano-type anticorrosion coating provided by the invention comprises the following components by weight percentage:

[0032]

[0033] Described aliphatic epoxy resin is aliphatic glycidyl ether epoxy resin, and its epoxy equivalent is 450, and viscosity 10000cps;

[0034] The anticorrosion inhibitor is prepared by the following method: Weigh the following components by weight: 36 parts of ethanol, 2 parts of polyethylene glycol, 2 parts of aluminate coupling agent, solvent-based nano-silica dispersion 30 parts, 13 parts of aluminum tripolysilicate, and 14 parts of zinc phosphate were added to the reaction kettle, stirred at a high speed at room temperature, and then heated to 80°C, and a mixture of 2.5 parts of hexamethylenetetramine and 1 part of cyclohexylamine was added dropwise. After the solution was added dropwise, it was incubated at 80° C. for 4 hours to obtain the anticorrosion inhibitor.

[0035] The solvent is prepared by mixing petrol...

Embodiment 3

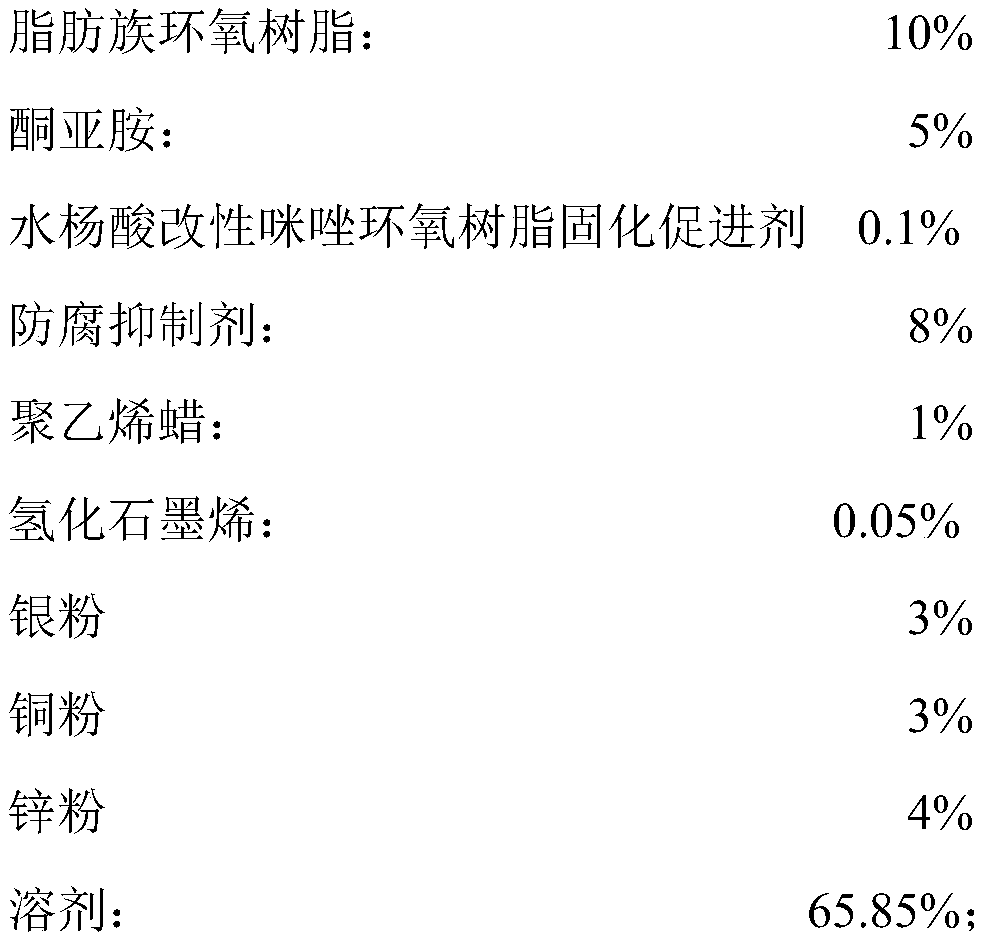

[0037] A kind of ultra-thin nano-type anticorrosion coating provided by the invention comprises the following components by weight percentage:

[0038]

[0039] Described phenolic modified epoxy resin epoxy equivalent 440, viscosity 7000cps;

[0040] The anticorrosion inhibitor is prepared by the following method: Weigh the following components by weight: 44 parts of ethanol, 3 parts of polyethylene glycol, 3 parts of aluminate coupling agent, 25 parts of solvent-based nano-silica dispersion 18 parts, 18 parts of aluminum tripolysilicate, 10 parts of zinc phosphate, add to the reaction kettle, stir evenly at a high speed at room temperature, then raise the temperature to 80°C, add dropwise a mixed solution of 3.5 parts of hexamethylenetetramine and 1 part of cyclohexylamine , after the dropwise addition was completed, the anticorrosion inhibitor was obtained by incubating at 80° C. for 4 hours.

[0041] The solvent is formed by mixing hexane and toluene at a volume ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com