Low-permeability sandstone oil deposit chromium-aluminum ion compound profile control agent and using method thereof

A sandstone reservoir and profile control agent technology, applied in chemical instruments and methods, earthwork drilling, production fluids, etc., can solve low-permeability sandstone reservoirs with less research on profile control, waxy, colloid, and asphaltene deposits , organic clogging and other problems, to achieve the effect of enhancing the adaptability of salinity, improving hydrophilicity and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

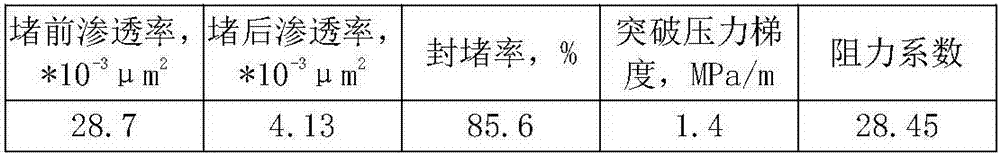

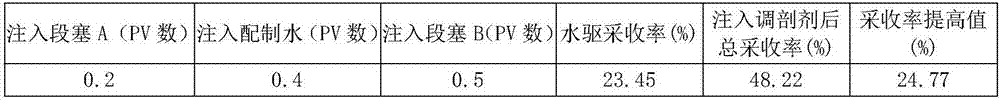

Embodiment 1

[0038] 1. The method of using the profile control agent: (1) First, carry out oxygen exposure treatment on the prepared water to reduce the dissolved oxygen content in the prepared water to less than 3 mg / L; (2) Add part of the hydrolysis polymer to the prepared water at a temperature of 15°C Acrylamide was stirred at a constant speed for 2 hours, then the additive was added to the prepared water and stirred at a constant speed for 3 hours to obtain the profile control agent; (3) After the preparation was completed, the profile control agent was directly injected into the rock core.

[0039] 2. Prepare water, adjust the salinity to 500mg / L by adding NaCl to the distilled water, so as to simulate the source water used in production.

[0040] 3. The specific application dosage is:

[0041] Slug A: The composite polymer is composed of three partially hydrolyzed polyacrylamides with different molecular weights, the molecular weights are 500*10 4 、800*10 4 、1000*10 4 , the mass ...

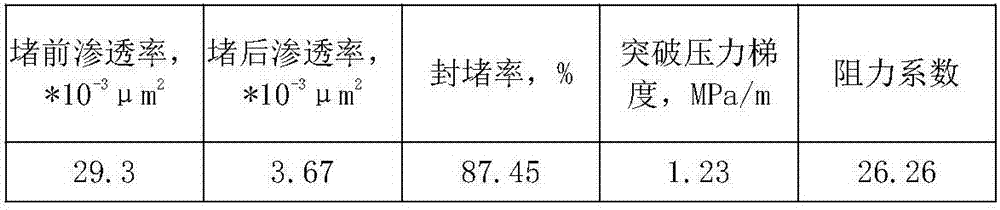

Embodiment 2

[0069] 1. The method of using the profile control agent: (1) Firstly, carry out oxygen exposure treatment on the prepared water to reduce the dissolved oxygen content in the prepared water to below 3 mg / L; (2) add part of the hydrolytic polymer to the prepared water at a temperature of 35°C Acrylamide was stirred at a constant speed for 2.5 hours, then the additive was added to the prepared water and stirred at a constant speed for 2.5 hours to obtain the profile control agent; (3) After the preparation was completed, the profile control agent was directly injected into the core.

[0070] 2. Prepare water, adjust the salinity to 8000mg / L by adding NaCl to the distilled water, to simulate the oil field sewage used in actual production.

[0071] 3. The specific application dosage is:

[0072] Slug A: The composite polymer is composed of three kinds of partially hydrolyzed polyacrylamide with different molecular weights, the molecular weights are 500*10 4 、800*10 4 、1000*10 4,...

Embodiment 3

[0100] 1. The method of using the profile control agent: (1) Firstly, carry out oxygen exposure treatment on the prepared water to reduce the dissolved oxygen content in the prepared water to below 3 mg / L; (2) add part of the hydrolytic polymer to the prepared water at a temperature of 55°C Acrylamide was stirred at a constant speed for 3 hours, and then the additive was added to the prepared water and stirred at a constant speed for 2 hours to obtain the profile control agent; (3) After the preparation was completed, the profile control agent was directly injected into the rock core.

[0101] 2. To prepare water, adjust the degree of salinity by adding soluble salts to the distilled water, and the final degree of salinity is 35000mg / L, which is used to simulate the oilfield sewage used in actual production.

[0102] 3. The specific application dosage is:

[0103] Slug A: The composite polymer is composed of three partially hydrolyzed polyacrylamides with different molecular w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com