Microchannel reactor

A technology of microchannel reactor and microchannel reaction, applied in chemical/physical/physical chemical reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc. The problem of large pressure drop and low conversion rate of raw materials can be solved, so as to achieve the effect of improving the conversion rate of raw materials, increasing the degree of turbulence, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

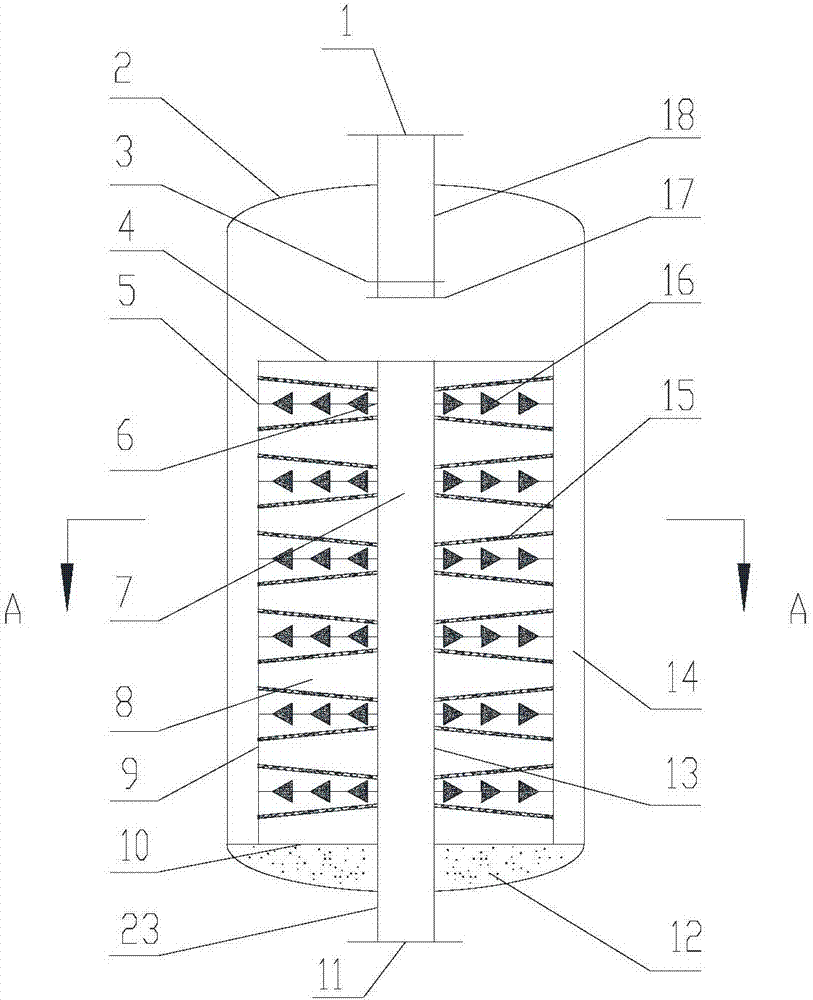

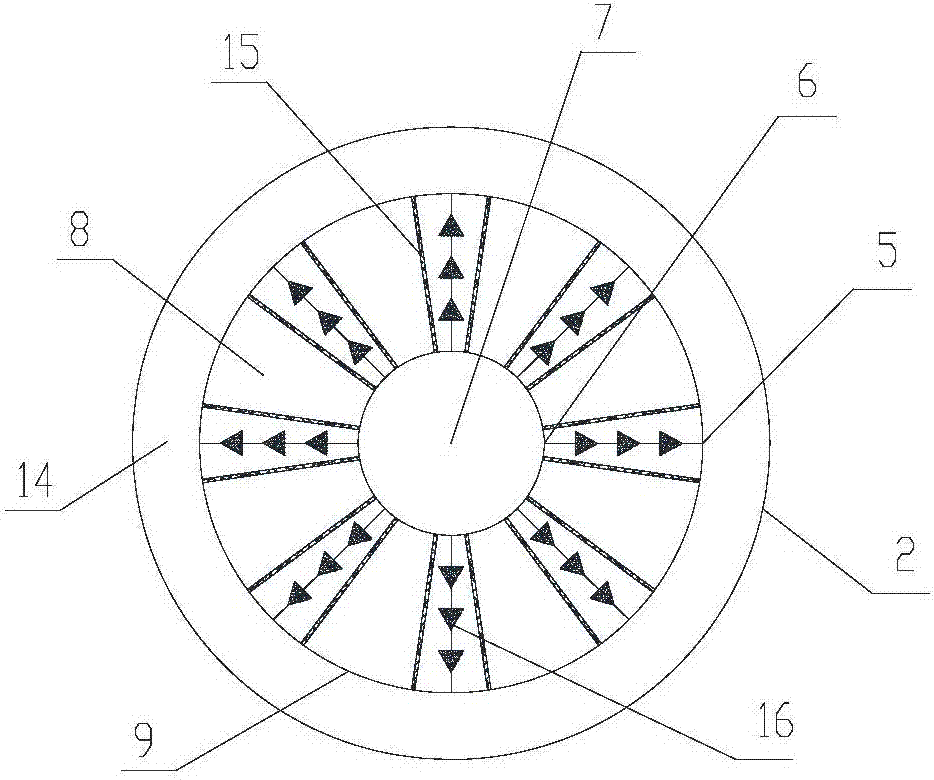

[0070] Such as figure 1 As shown, the microchannel reactor used in this embodiment includes a radial cylindrical sealed pressure-bearing shell 2, an air inlet pipe 18, an air outlet pipe 23 and a radial catalytic reaction zone. The upper part of the air intake pipe 18 is provided with an air inlet 1 , the lower part is provided with a first gas distributor 3 , and the lower part of the first gas distributor 3 is provided with a second gas distributor 17 . Between the radial catalytic reaction zone and the bottom surface of the casing 2, a thermal insulation material zone 12 composed of a thermal insulation blanket is arranged. The radial catalytic reaction zone includes a coaxial central cylinder 8, which is in sealing connection with the top sealing plate 4 and the bottom sealing plate 10. There is an annular gap 14 between the central cylinder 8 and the shell 2, and the annular gap 14 is connected to the air intake pipe 18. Fluid communication, the central cylinder 8 has a ...

Embodiment 2

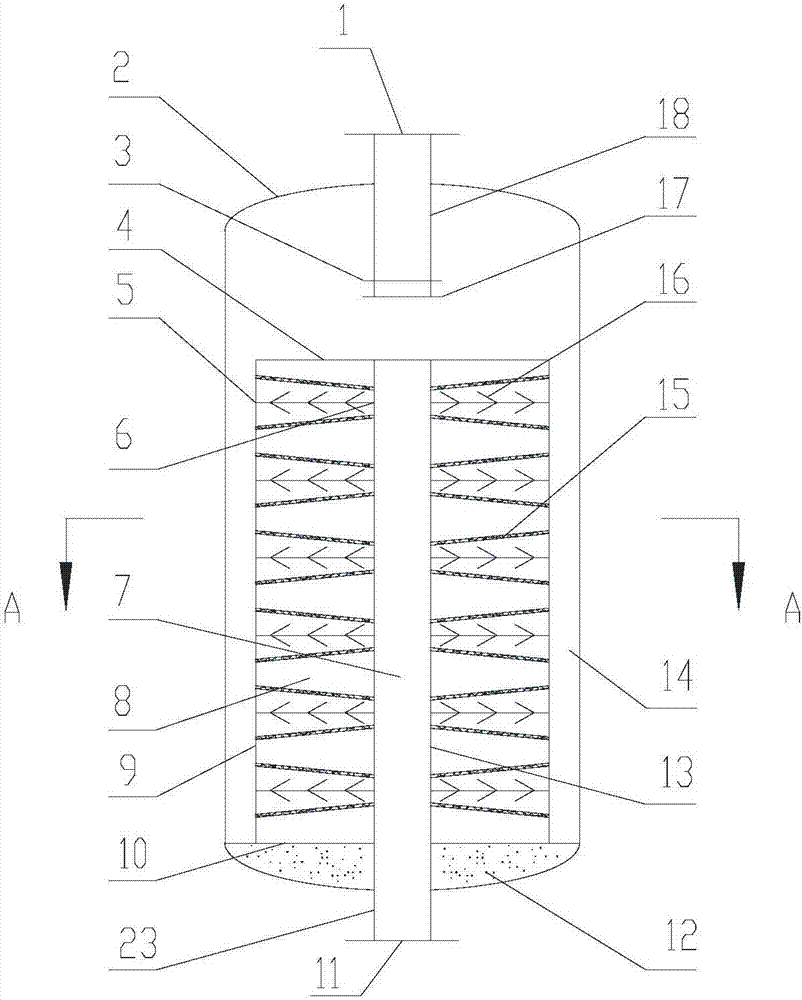

[0075] Such as image 3 , Figure 4 As shown, the structural parameters such as the inner diameter of the reactor shell, the height of the catalytic reaction zone, and the number of microchannels in the reactor of this embodiment are exactly the same as those of the reactor in Embodiment 1. The difference from Embodiment 1 is that in this embodiment, the flow guide element 25 is replaced by a conical surface, and the conical surface is also fixed by a fixed shaft, and the size of the conical surface is the same as that of the cone. The microchannel reactor can also be used for methanation reactions. The process conditions adopted in Example 1 are the same, and the conversion rate of raw materials obtained is consistent with the implementation.

Embodiment 3

[0077] Such as Figure 5 , Figure 6 As shown, the structural parameters such as the inner diameter of the reactor shell, the height of the catalytic reaction zone, and the number of microchannels in the reactor of this embodiment are exactly the same as those of the reactor in Embodiment 1. The difference from Example 1 is that in this embodiment, the flow guide element is replaced by a cone with a hemispherical surface, and the hemispherical surface is also fixed by a fixed shaft. The diameter of the spherical surface is 3mm, and the distance between the two spherical surfaces is 5mm. Each flow guide assembly contains There are 38 hemispherical guide elements, and the hemispherical surfaces are uniformly concave and set in the direction of the central tube.

[0078] The reactor proposed in this embodiment is applied to the reaction of coal-based synthesis gas to light olefins (C 2 = -C 4 = ), the amount of active metal Fe loaded in the conical tube is 11.0g / m 2 . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com