Self-protecting medicine cored wire material for large-scale hot-forging die sandwich layer and preparation method thereof

A technology of core wire material and hot forging die, which is applied in the field of welding material manufacturing, can solve the problems of low bonding strength, poor elastic deformation and stress diffusion ability of the sandwich layer, poor forming quality of the sandwich layer and poor welding process performance, etc., to achieve stacking The effect of low welding efficiency, heavy welding workload and high surfacing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

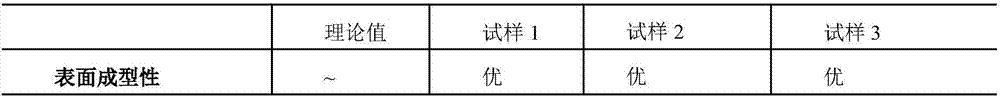

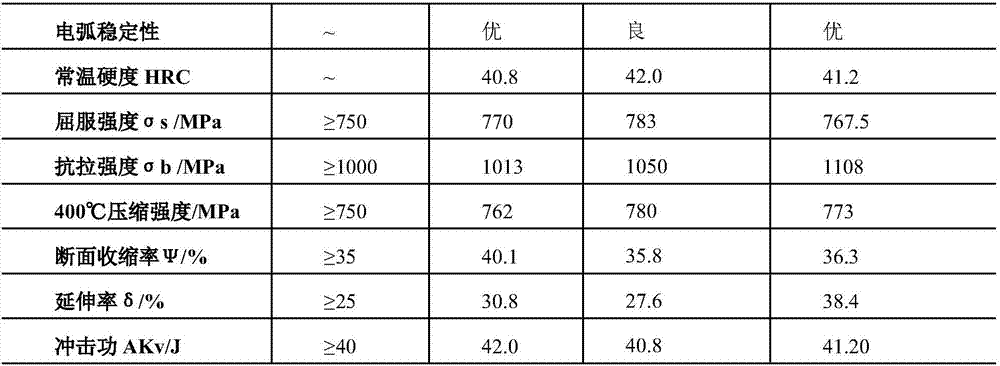

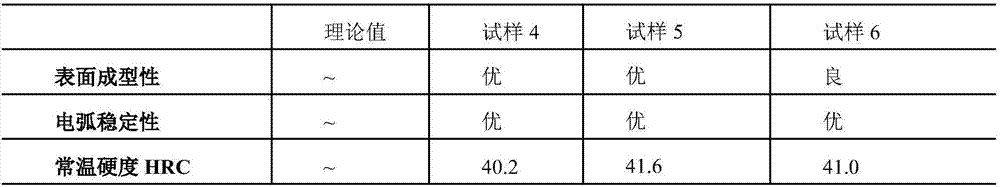

Embodiment 1

[0023] 1) Dry the raw materials at 120°C for 1 hour respectively, use 80-mesh sieves to sieve the dried raw materials, and store the sifted raw materials at 80°C for later use;

[0024] 2) Weigh the drug core raw materials in the drug core wire according to the following proportions: carbon element content 0.32%, silicon element content 0.4%, manganese element content 1%, phosphorus element content 0.01%, sulfur element content 0.01%, chromium element content content of 2.2%, nickel element content of 2.1%, molybdenum element content of 1.4%, vanadium element content of 16%, and the balance of iron, the weighed raw materials were added to a mixer and mixed for 2 hours to obtain drug core powder;

[0025] 3) Obtain the H08A steel strip for ultrasonic cleaning and drying, process the cross section of the H08A steel strip into a U-shaped structure, and then add the drug core powder obtained in step 2) into the H08A steel strip with a powder feeder and then roll it Forming, and th...

Embodiment 2

[0032] 1) Dry the raw materials at 120°C for 1 hour respectively, use 80-mesh sieves to sieve the dried raw materials, and store the sifted raw materials at 80°C for later use;

[0033] 2) Weigh the drug core raw materials in the drug core wire according to the following proportions: carbon element content 0.24%, silicon element content 0.2%, manganese element content 0.8%, phosphorus element content 0.01%, sulfur element content 0.01%, chromium element content content of 1.8%, nickel element content of 1.8%, molybdenum element content of 1.2%, vanadium element content of 13%, and the balance of iron, the weighed raw materials were added to a mixer and mixed for 2 hours to obtain drug core powder;

[0034] 3) Obtain the H08A steel strip for ultrasonic cleaning and drying, process the cross section of the H08A steel strip into a U-shaped structure, and then add the drug core powder obtained in step 2) into the H08A steel strip with a powder feeder and then roll it Forming, and ...

Embodiment 3

[0041] 1) Dry the raw materials at 120°C for 1 hour respectively, use 80-mesh sieves to sieve the dried raw materials, and store the sieved raw materials at 80°C for later use;

[0042] 2) Weigh the drug core raw materials in the drug core wire according to the following proportions: carbon element content 0.4%, silicon element content 0.6%, manganese element content 1.2%, phosphorus element content 0.01%, sulfur element content 0.01%, chromium element content content of 2.5%, nickel element content of 2.5%, molybdenum element content of 1.6%, vanadium element content of 18%, and the balance of iron, the weighed raw materials were added to a mixer and mixed for 2 hours to obtain drug core powder;

[0043] 3) After the H08A steel strip is obtained for ultrasonic cleaning and drying, the cross section of the H08A steel strip is processed into a U-shaped structure, and then the core powder obtained in step 2) is added to the H08A steel strip with a powder feeder and then rolled F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com