Positive electrode material for potassium ion battery and preparation method thereof, and potassium ion battery

A battery positive electrode and positive electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as climate warming, resource depletion, obstacles, etc., and achieve simple process, low raw material cost, and maintain structural stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Weigh potassium ferricyanide and ferrous chloride at a molar ratio of 1:1, disperse them in deionized water, and stir at 30°C for 30 minutes to form a uniform solution;

[0038] 2) Transfer the solution prepared in step 1) to a polytetrafluoroethylene liner, seal it in a reaction kettle, and conduct a hydrothermal reaction at 80° C. for 12 hours;

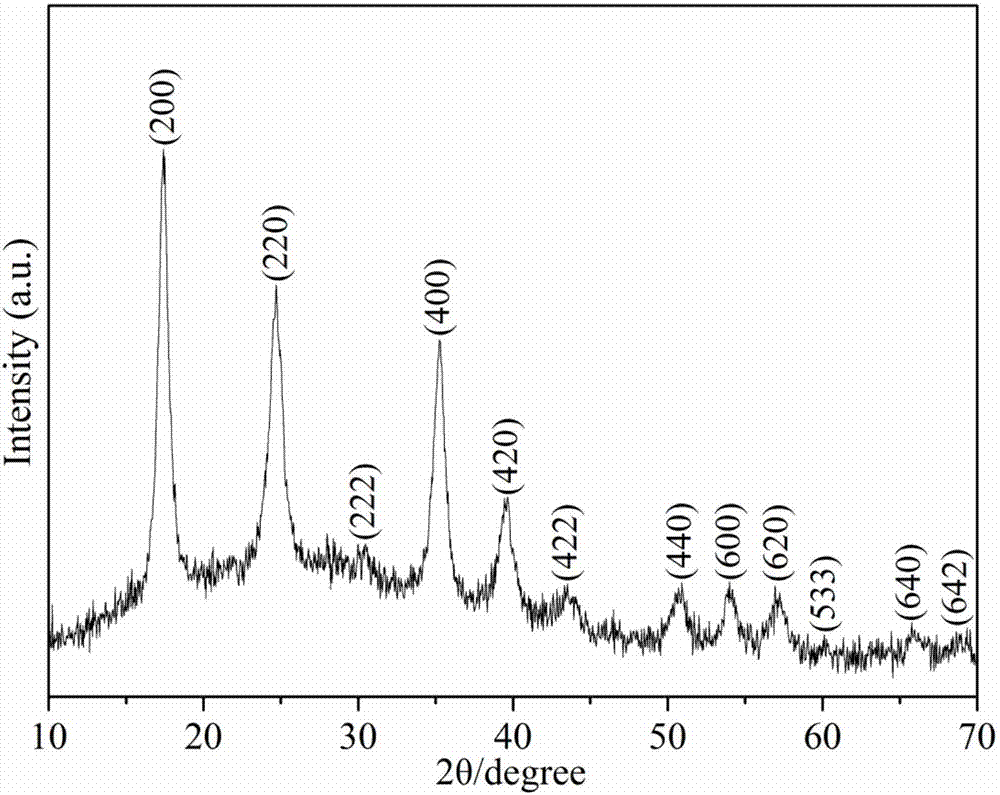

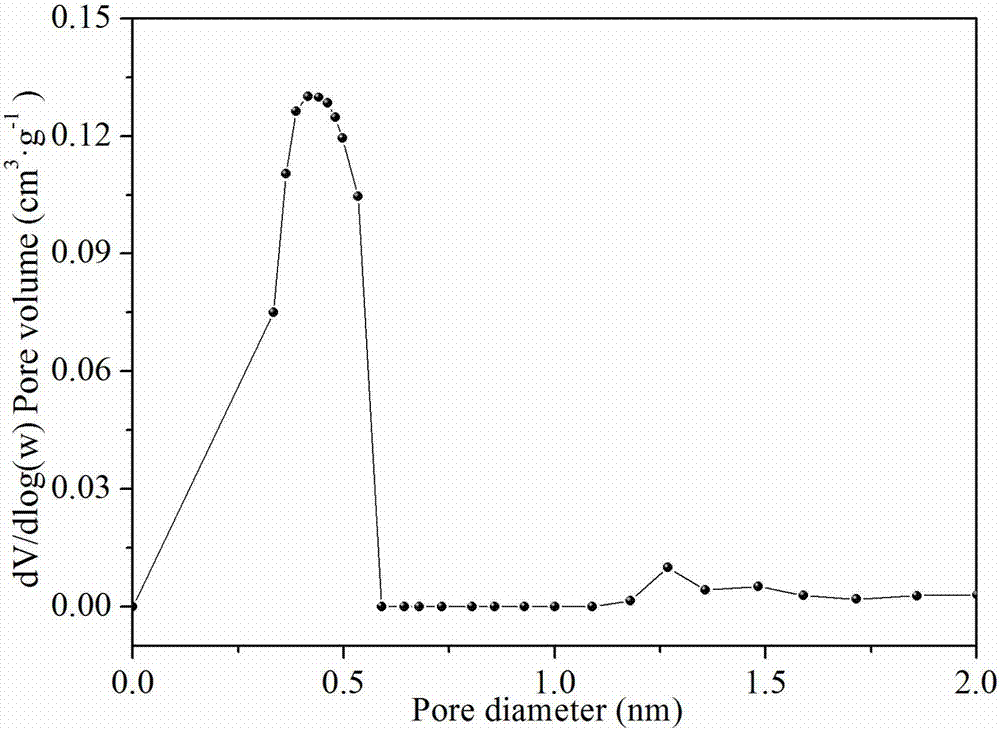

[0039] 3) After the reaction, the precipitate in the product is separated by a high-speed centrifuge, washed with deionized water for more than 3 times, and then vacuum-dried at a pressure of 20kPa and a temperature of 60°C for 12h to obtain the positive electrode material iron for potassium ion batteries. Potassium ferrous cyanide KFe 2+ [Fe 3+ (EN) 6 ].

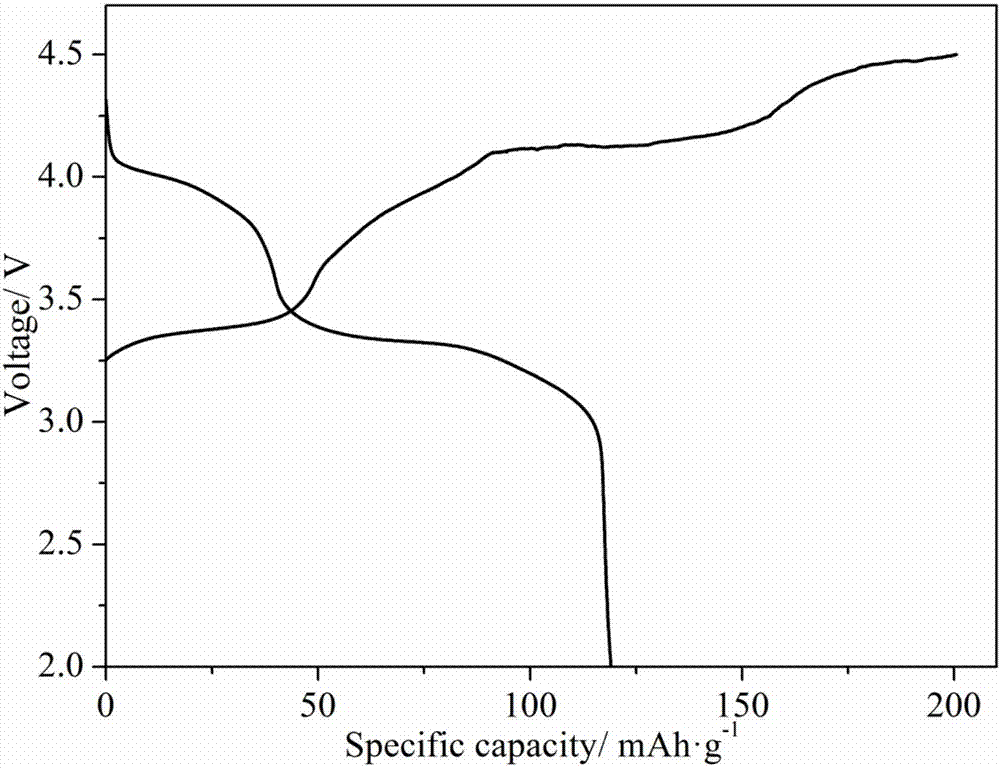

[0040] Potassium ferricyanide potassium ferricyanide KFe, the positive electrode material of potassium ion battery prepared by embodiment 1 2+ [Fe 3+ (EN) 6 ] and acetylene black conductive agent, PVDF (polyvinylidene fluoride) binder according to the mass ratio o...

Embodiment 2

[0046] 1) Weigh potassium ferrocyanide and ferrous nitrate at a molar ratio of 1:1, disperse them in absolute ethanol, and stir at 60°C for 20 minutes to form a uniform solution;

[0047] 2) Transfer the solution prepared in step 1) to a polytetrafluoroethylene liner, seal it in a reaction kettle, and conduct a hydrothermal reaction at 60° C. for 15 hours;

[0048] 3) After the reaction, the precipitate in the product was separated by vacuum filtration, washed with absolute ethanol for more than 3 times, and then vacuum-dried at a pressure of 10kPa and a temperature of 50°C for 15h to obtain the sub- Potassium ferricyanide K 2 Fe 2+ [Fe 2+ (EN) 6 ].

[0049] Potassium ion battery positive electrode material potassium ferrocyanide K that embodiment 2 makes 2 Fe 2+ [Fe 2+ (EN) 6 ] The process of preparing the positive electrode sheet and assembling the button cell is the same as in Example 1.

[0050] Figure 5 Potassium ferrocyanide potassium ferrocyanide for the pota...

Embodiment 3

[0054] 1) Weigh potassium ferrocyanide and nickel nitrate at a molar ratio of 1:1, disperse them in deionized water, and stir at 25°C for 60 minutes to form a uniform solution;

[0055] 2) Transfer the solution prepared in step 1) to a polytetrafluoroethylene liner, seal it in a reaction kettle, and conduct a hydrothermal reaction at 70° C. for 12 hours;

[0056] 3) After the reaction is over, the precipitate in the product is separated by a high-speed centrifuge, washed with deionized water for more than 3 times, and then vacuum-dried for 10 hours at a pressure of 20kPa and a temperature of 80°C to obtain sub- Potassium Nickel Ferricyanide K 2 Ni 2+ [Fe 2+ (EN) 6 ].

[0057] Potassium ion battery positive electrode material potassium ferrocyanide K that embodiment 3 makes 2 Ni 2+ [Fe 2+ (EN) 6 ] The process of preparing the positive electrode sheet and assembling the button cell is the same as in Example 1.

[0058] Figure 8 Potassium nickel ferrocyanide K for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com