Negative electrode material, preparation method thereof and sodium ion battery containing negative electrode material

A negative electrode material, in-situ preparation technology, applied in the direction of negative electrodes, battery electrodes, secondary batteries, etc., can solve the problems of dispersed pore structure, strong corrosion, environmental pollution, etc., and achieve large specific surface area and high current charge and discharge performance The effect of stability and outstanding magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) According to the mass ratio chitosan:sodium chloride=1:1, weigh 2g chitosan and 2g sodium chloride respectively.

[0065] (2) Add 80mL deionized water into the beaker, add the weighed sodium chloride and stir at room temperature until completely dissolved.

[0066] (3) Add the chitosan powder into the sodium chloride solution, stir well, measure 1mL of glacial acetic acid and add it dropwise into the solution. During this process, the solution will become very viscous, and magnetic stirring should be strengthened. Stirring was continued for 12 hours until the solution was translucent.

[0067] (4) The colloid obtained in (3) was transferred to a freezing environment for 12 hours, and then vacuum-dried for 72 hours to obtain a precursor.

[0068] (5) Put the substance in a porcelain boat, heat it to 1200° C. under an argon atmosphere, and keep it warm for 2 hours to obtain a carbonized material.

[0069] (6) Put the carbonized material obtained in (5) into a mortar...

Embodiment 2

[0072] (1) According to the method of Example 1, the difference is that the heat treatment time is 4 hours and the temperature is 1200° C. to obtain the corresponding negative electrode powder material, which is marked as S2.

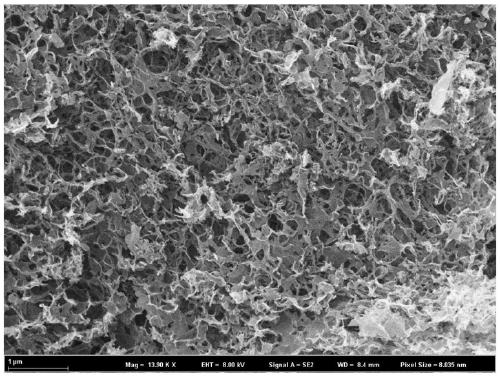

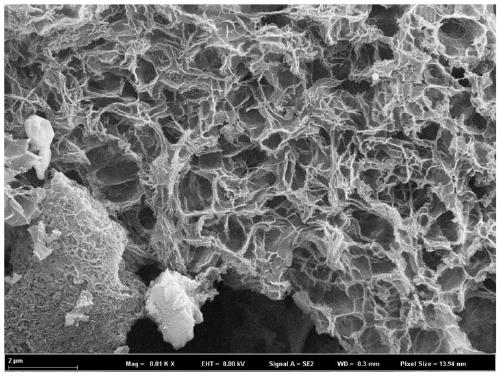

[0073] Carry out scanning electron microscope analysis to embodiment 2 see figure 2 , wherein the material structure prepared by sodium chloride under this condition is similar to that of Example 1, both having a porous network structure.

Embodiment 3

[0075] (1) Carry out according to the method for embodiment 1, wherein difference is that the temperature of heat treatment is 1400 ℃, and the time is heat preservation 2 hours. The corresponding negative electrode powder material was obtained, marked as S3.

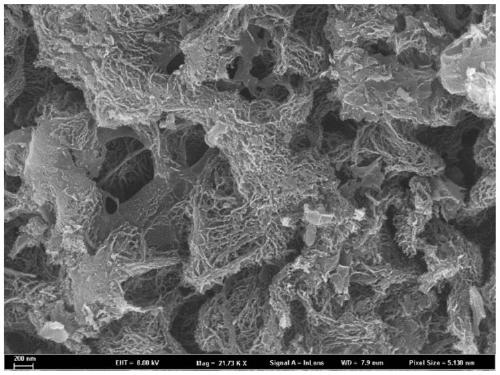

[0076] The negative electrode material powder that embodiment 3 is obtained is observed under scanning electron microscope, and scanning electron microscope picture is as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com