Preparation method and array of titanium dioxide nanorod array with branched structure on top

A nanorod array and titanium dioxide technology, applied in the field of nanomaterials, can solve the problems of limited nanorod distance in branch structure, inability to use nanorods, poor chemical stability, etc., and achieve the effects of easy promotion, low cost and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

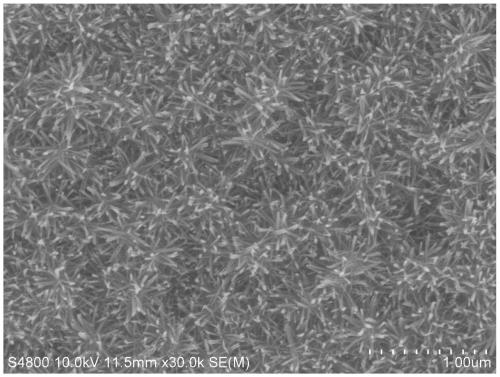

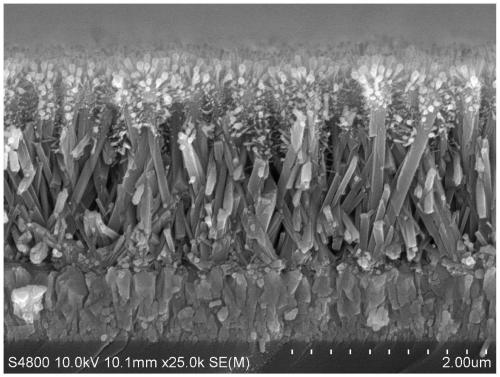

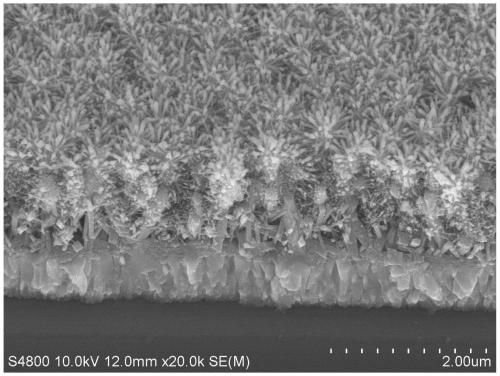

[0021] A method for preparing a titanium dioxide nanorod array with a branched structure on the top, comprising: sputtering metal titanium nanoparticles on the top of the titanium dioxide nanorod array grown on a conductive substrate, and sintering for the first time to obtain a composite array; Place in the hydrochloric acid solution of tetrabutyl titanate, hydrothermally react at 130-180°C for 2-5 hours, and sinter for the second time. The concentration of tetrabutyl titanate in the hydrochloric acid solution of tetrabutyl titanate is 0.005-0.02mol / L.

[0022] The conductive substrate is preferably FTO conductive glass or ITO conductive glass, which has the advantages of good transparency to visible light, large ultraviolet absorption coefficient, low resistivity, stable chemical properties, and strong acid and alkali resistance at room temperature, making titanium dioxide nanorods The array has good basic photoelectric performance.

[0023] Further, the titania nanorods o...

Embodiment 1

[0042] TiO grown on FTO conductive glass 2 The nanorod array is used as the substrate, and the DC magnetron sputtering method is used, and the sputtering vacuum background is 6×10 -6 Torr, the sputtering pressure is 8mTorr, the sputtering power is 100W, the target base distance is 20cm, and the conductive substrate rotation speed is 6r / min at room temperature. 2 The sputtering time of nanoparticles deposited on the surface of the nanorod array was 60min, and the match-like TiO was prepared 2 Composite arrays of nanoparticles and nanorods. After sputtering, it was annealed in air at 450° C. for 60 minutes to obtain a composite array.

[0043] Measure 12.5ml of deionized water and 12.5ml of 36%-38%wt hydrochloric acid, mix and stir for 5 minutes, add tetrabutyl titanate to prepare a reaction solution with a concentration of 0.015mol / L of tetrabutyl titanate, Stirring was continued for 5 min to obtain a precursor solution. Put the composite array into the inner lining of the ...

Embodiment 2

[0045] TiO grown on FTO conductive glass 2 The nanorod array is used as the substrate, and the DC magnetron sputtering method is used, and the sputtering vacuum background is 6×10 -6 Torr, the sputtering pressure is 12mTorr, the sputtering power is 120W, the target base distance is 20cm, and the conductive substrate rotation speed is 6r / min at room temperature. 2 The sputtering time of nanoparticles deposited on the surface of the nanorod array was 60min, and the match-like TiO was prepared 2 Composite arrays of nanoparticles and nanorods. After sputtering, it was annealed in air at 450° C. for 60 minutes to obtain a composite array.

[0046] Measure 12.5ml of deionized water and 12.5ml of 36%-38%wt hydrochloric acid, mix and stir for 5 minutes, add tetrabutyl titanate to prepare a reaction solution with a concentration of 0.02mol / L of tetrabutyl titanate , continue stirring for 5 min to obtain a precursor solution. Put the composite array into the inner lining of the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com