Preparation method of high-density and high-stability small network magnet ring

A high-stability, high-density technology, applied in the field of soft magnetic materials, can solve problems such as large inductance changes and inductance value drop due to stress, and achieve the effects of reducing core stress, shortening subsequent sintering time, and shortening sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

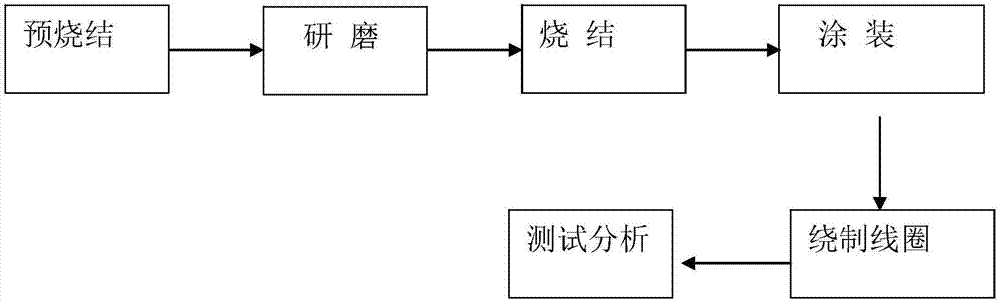

Method used

Image

Examples

Embodiment 1

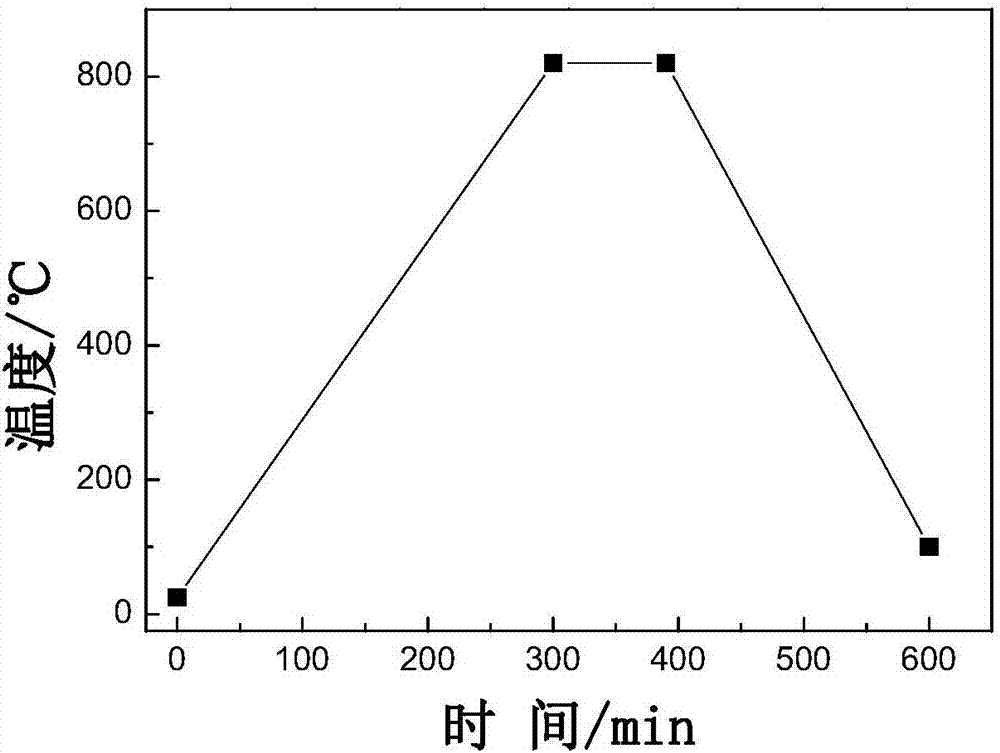

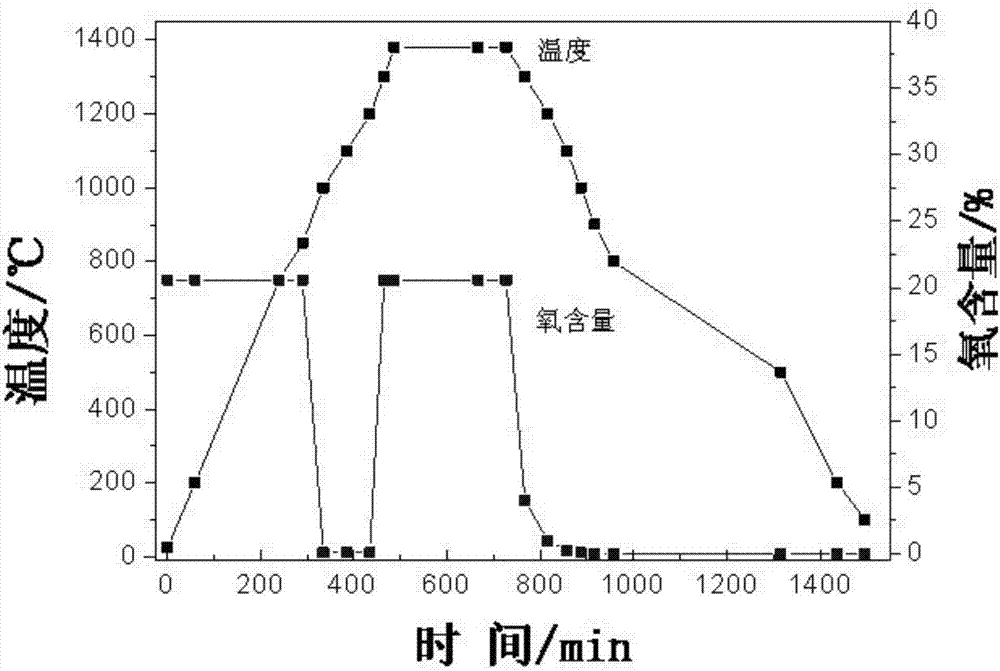

[0022] The magnetic core blank formed by dry pressing, the iron core model selected in this embodiment is R10KH2.54*1.40*0.76, is placed in a vertical furnace and sintered in three stages, and the sintering temperature is raised from room temperature to 780 ℃, 820℃, 860℃, 900℃, respectively recorded as samples 1~4, all kept at the corresponding temperature for 1.5 hours, the following treatment methods were the same for the four samples, and finally the temperature was lowered to below 100℃ after 4.5 hours .

[0023] Take the pre-sintered magnetic core and put it into a grinder, and at the same time add grinding medium balls of the same material as the magnetic core to the grinder for grinding. The weight percentage of the magnetic core and the grinding medium ball is 1:6, the speed of the grinder is 20 rpm, and the grinding time is 1 hour. Clean the dust and sundries on the surface of the ground magnetic core with hot water at 80-99°C, and put the rinsed magnetic core into a...

Embodiment 2

[0037] The magnetic core blank formed by dry pressing, the iron core model selected in this embodiment is R10KH2.54*1.40*0.76, and the test of 4 identical samples is carried out at the same time, recorded as samples 5-8, placed in a vertical furnace and divided into three For sintering in three stages, the sintering temperature was increased from room temperature to 820°C over 5 hours, kept at 820°C for 1.5 hours, and finally the temperature was lowered to below 100°C after 4.5 hours.

[0038] Take the pre-sintered magnetic core and put it into a grinder, and at the same time add grinding medium balls of the same material as the magnetic core to the grinder for grinding. The weight percentage of the magnetic core and the grinding medium ball is 1:6, the speed of the grinder is 20 rpm, and the grinding time is 1 hour.

[0039] Clean the dust and debris on the surface of the ground magnetic core with hot water at 80-99°C, and put the rinsed magnetic core into an oven to bake to ...

Embodiment 3

[0052] The magnetic core blank formed by dry pressing, the iron core model selected in this embodiment is R10KH2.54*1.40*0.76, and the test of 4 identical samples is carried out at the same time, recorded as samples 9-12, placed in a vertical furnace and divided into three For sintering in three stages, the sintering temperature was increased from room temperature to 820°C over 5 hours, kept at 820°C for 1.5 hours, and finally the temperature was lowered to below 100°C after 4.5 hours.

[0053] Take the pre-sintered magnetic core and put it into a grinder, and at the same time add grinding medium balls of the same material as the magnetic core to the grinder for grinding. The weight percentage of the magnetic core and the grinding medium ball is 1:6, the speed of the grinder is 20 rpm, and the grinding time is 1 hour. Clean the dust and debris on the surface of the ground magnetic core with hot water at 80-99°C, and put the rinsed magnetic core into an oven to bake to remove w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com