Bipolar electrode, lithium ion battery and fabrication method of lithium ion battery

A technology for bipolar electrodes and lithium-ion batteries, applied in bipolar electrodes, active material electrodes, electrode carriers/collectors, etc., can solve the problems of complex manufacturing process, easy holes, uneven distribution of conductive particles, etc., to achieve The process is simple, the effect of reducing liquid junction short circuit and preventing partial short circuit at the edge of bipolar current collector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] A lithium ion battery, its manufacture method is as follows

[0075] (1) Preparation of conductive paste

[0076] According to 100% by mass, the conductive paste is

[0077] Carbon black (SP) 2%;

[0078] Epoxy resin 4%;

[0079] NMP solvent 94%;

[0080] Mix and stir the above formula components to form a conductive paste.

[0081] (2) Production of bipolar electrodes:

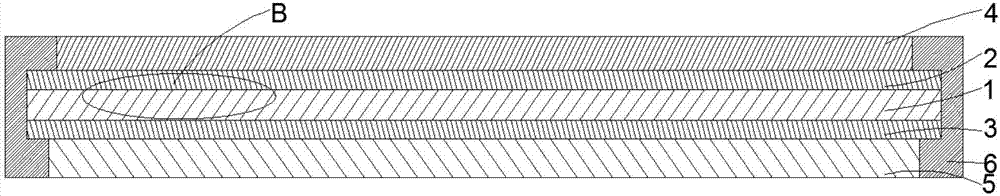

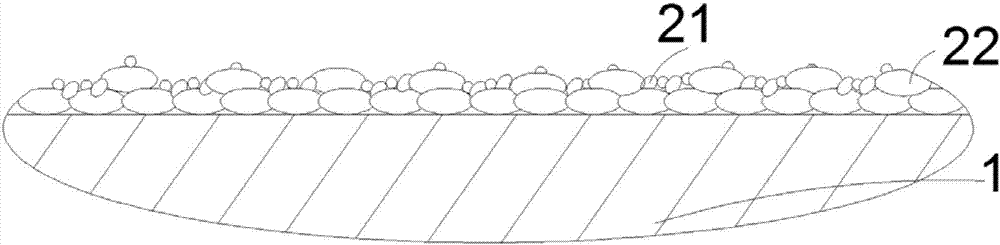

[0082] Such as figure 2 As shown, the 20 μm copper-aluminum composite foil is used as the current collector 1 of the bipolar electrode, and the conductive paste in step (1) is evenly coated on the front and back sides of the current collector according to a certain surface density, and dried to obtain The first conductive layer 2 and the second conductive layer 3

[0083] Will be made of positive electrode active material LiCoO 2 , conductive agent SP, and binder PVDF are mixed with NMP and stirred to obtain a uniformly dispersed positive electrode slurry, which is coated on the surface coated...

Embodiment 2

[0089] A lithium ion battery, its manufacture method is as follows

[0090] (1) Preparation of conductive paste

[0091] According to 100% by mass, the conductive paste is

[0092] Carbon black (SP) 2%;

[0093] Epoxy resin 4%;

[0094] NMP solvent 94%

[0095] Mix and stir the above formula components to form a conductive paste.

[0096] (2) Production of bipolar electrodes:

[0097] Such as figure 2 As shown, the 20 μm copper-aluminum composite foil is used as the current collector 1 of the bipolar electrode, and the conductive paste in step (1) is evenly coated on the front and back sides of the current collector according to a certain surface density, and dried to obtain The first conductive layer 2 and the second conductive layer 3

[0098] Will be made of positive electrode active material LiCoO 2 , conductive agent SP, and binder PVDF are mixed with NMP and stirred to obtain a uniformly dispersed positive electrode slurry, which is coated on the surface of the ...

Embodiment 3

[0104] A lithium ion battery, its manufacture method is as follows

[0105] (1) Preparation of conductive paste

[0106] According to 100% by mass, the conductive paste is

[0107] Carbon black (SP) 2%;

[0108] Polyvinylidene fluoride 4%;

[0109] NMP solvent 94%;

[0110] Mix and stir the above formula components to form a conductive paste.

[0111] (2) Production of bipolar electrodes:

[0112] Such as figure 2 As shown, the 16 μm aluminum foil is used as the current collector 1 of the bipolar electrode, and the conductive paste in step (1) is evenly coated on the front and back sides of the current collector according to a certain surface density, and dried to obtain the first conductive paste. layer 2 and second conductive layer 3

[0113] The positive electrode active material LiNi 0.5 co 0.2 mn 0.3 o 2 , the conductive agent CNTs, and the binder PVDF are mixed with NMP and stirred to obtain a uniformly dispersed positive electrode slurry, which is coated on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com