A preparation process of super large grinding wheel reinforced glass fiber mesh

A technology of glass fiber mesh and glass fiber, which is applied in the field of preparation technology of super large grinding wheel reinforced glass fiber mesh, can solve the problem of weak bonding force between mesh and sand and resin in the grinding wheel, poor color fastness of glass fiber yarn, and bonding Solve problems such as single agent formula, achieve the effect of ensuring color fastness, ensuring color fastness, and improving washing and friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

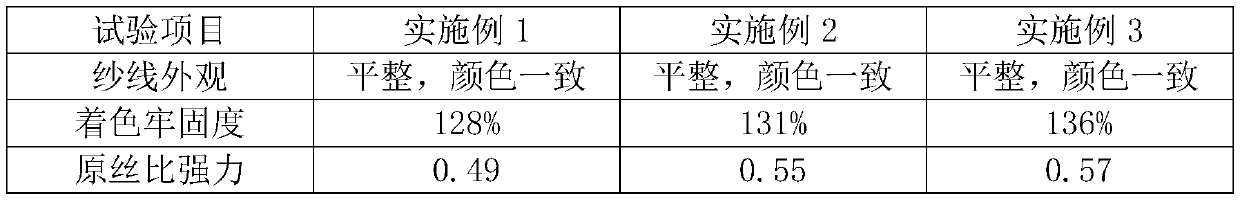

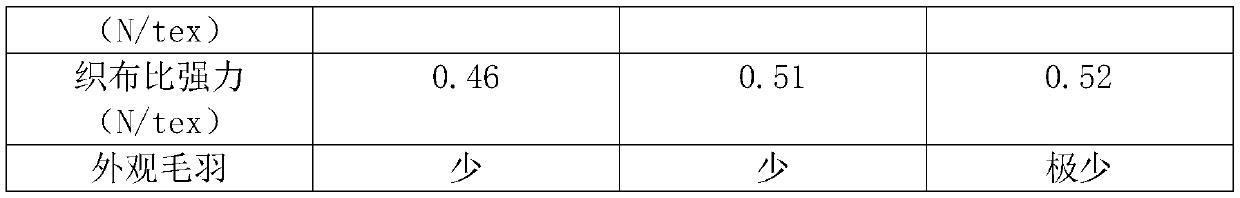

Embodiment 1

[0028] The preparation process of the super large grinding wheel reinforced glass fiber mesh in this embodiment comprises the following steps:

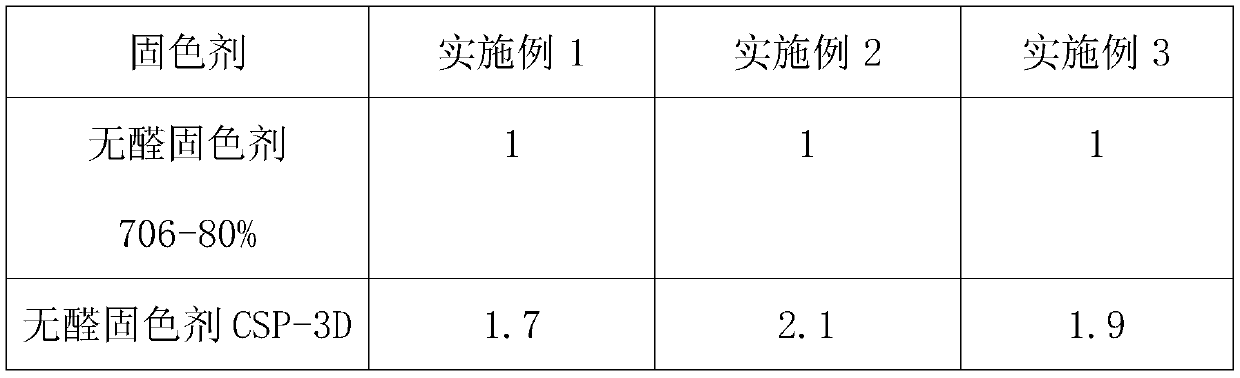

[0029](1) Impregnation treatment: Send the drawn glass fiber filaments into the impregnation treatment tank for impregnation treatment to form glass fiber yarn, wherein the impregnating agent in the impregnation treatment tank is prepared from the following components by mass percentage: water-soluble ring Oxygen resin 681 5%, water-soluble polyester resin SR-1 3%, color fixing agent 4% (formaldehyde-free color fixing agent 706-80% 1.48% and formaldehyde-free color fixing agent CSP-3D 2.52%), stearic acid 3 %, paraffin wax 1.5%, Pingping plus O-10 1.5%, Pingping plus O-25 1.5%, silane coupling agent KH-550 0.06% and the balance of deionized water;

[0030] (2) Weaving glass fiber mesh: the glass fiber yarn of step (1) is wound on the winding wire, and forms glass fiber mesh by unwinding, plying, warping and weaving;

[0031] (3) Prep...

Embodiment 2

[0035] The preparation process of the super large grinding wheel reinforced glass fiber mesh in this embodiment comprises the following steps:

[0036] (1) Impregnation treatment: Send the drawn glass fiber filaments into the impregnation treatment tank for impregnation treatment to form glass fiber yarn, wherein the impregnating agent in the impregnation treatment tank is prepared from the following components by mass percentage: water-soluble ring Oxygen resin 681 5%, water-soluble polyester resin SR-1 3%, color fixing agent 4% (formaldehyde-free color fixing agent 706-80% 1.29% and formaldehyde-free color fixing agent CSP-3D 2.71%), stearic acid 3 %, paraffin wax 1.5%, Pingping plus O-10 1.5%, Pingping plus O-25 1.5%, silane coupling agent KH-550 0.06% and the balance of deionized water;

[0037] (2) Weaving glass fiber mesh: the glass fiber yarn of step (1) is wound on the winding wire, and forms glass fiber mesh by unwinding, plying, warping and weaving;

[0038] (3) Pre...

Embodiment 3

[0042] The preparation process of the super large grinding wheel reinforced glass fiber mesh in this embodiment comprises the following steps:

[0043] (1) Impregnation treatment: Send the drawn glass fiber filaments into the impregnation treatment tank for impregnation treatment to form glass fiber yarn, wherein the impregnating agent in the impregnation treatment tank is prepared from the following components by mass percentage: water-soluble ring Oxygen resin 681 5%, water-soluble polyester resin SR-1 3%, color fixing agent 4% (formaldehyde-free color fixing agent 706-80% 1.38% and formaldehyde-free color fixing agent CSP-3D 2.62%), stearic acid 3 %, paraffin wax 1.5%, Pingping plus O-10 1.5%, Pingping plus O-25 1.5%, silane coupling agent KH-550 0.06% and the balance of deionized water;

[0044] (2) Weaving glass fiber mesh: the glass fiber yarn of step (1) is wound on the winding wire, and forms glass fiber mesh by unwinding, plying, warping and weaving;

[0045] (3) Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com