Preparation method and application of graphene-like structure carbon electrode material

A graphene and carbon electrode technology, which is applied in the preparation/purification of carbon, hybrid capacitor electrodes, etc., can solve the problems of difficult conversion of results, and achieve the effects of low cost, large specific surface, and good graded pore distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

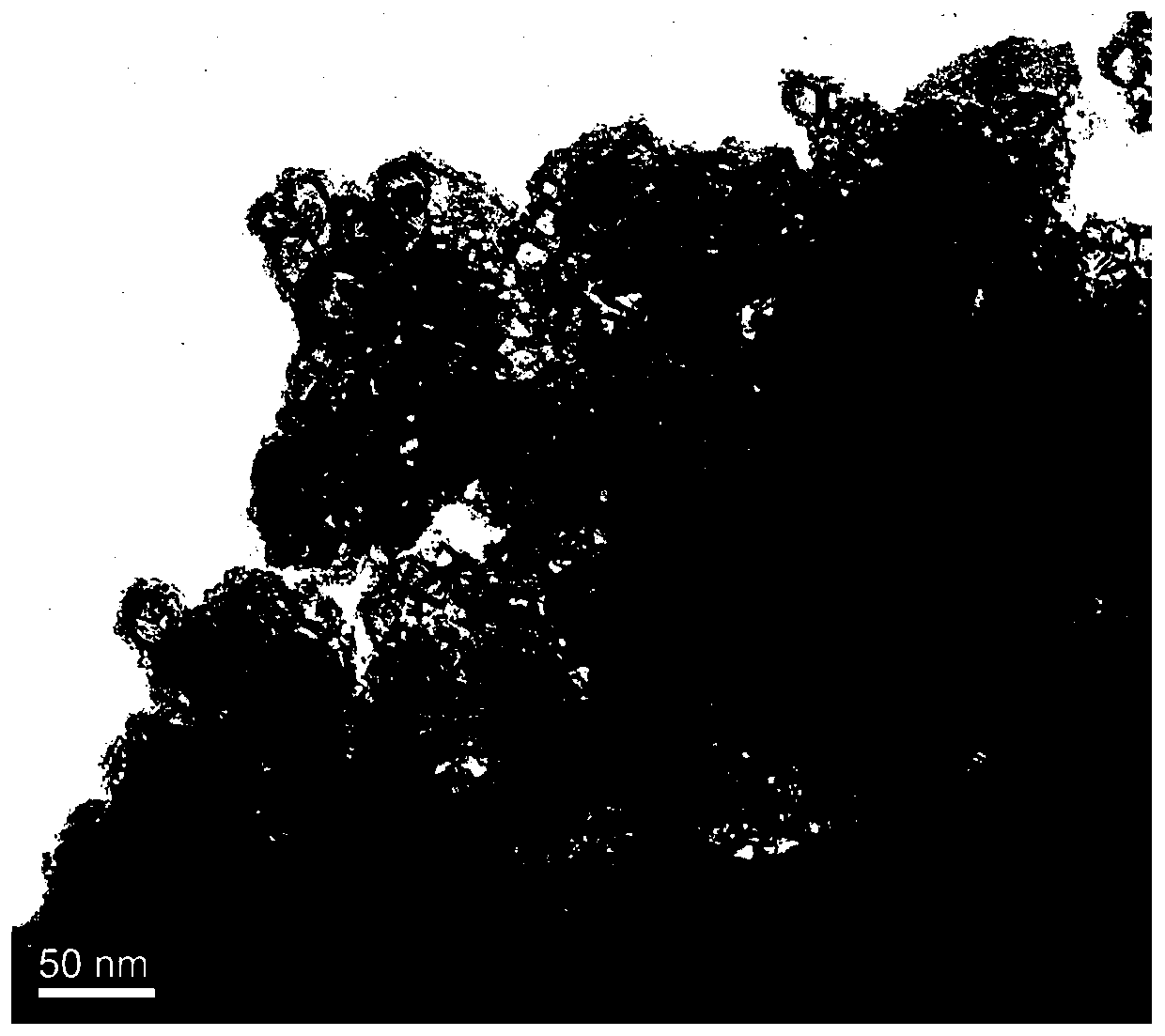

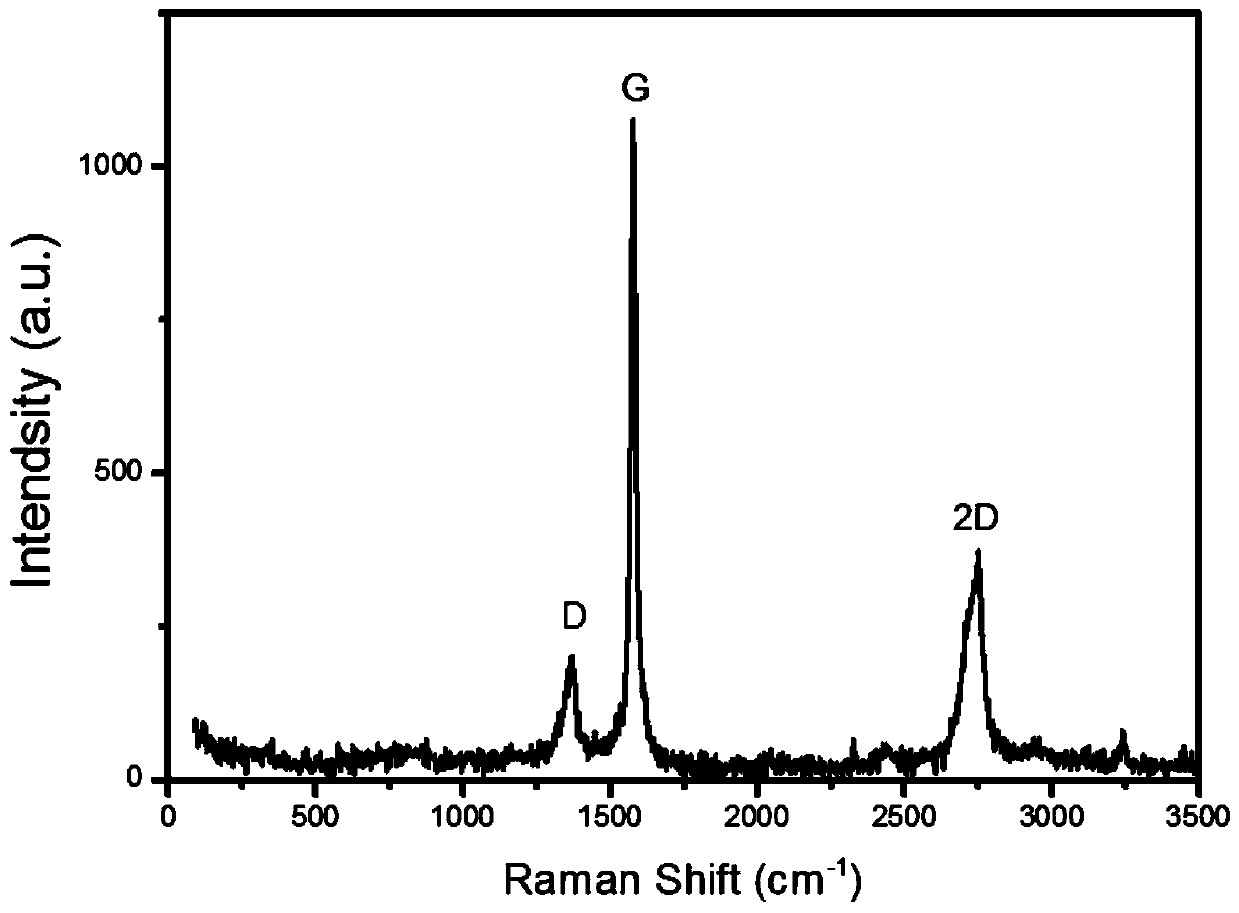

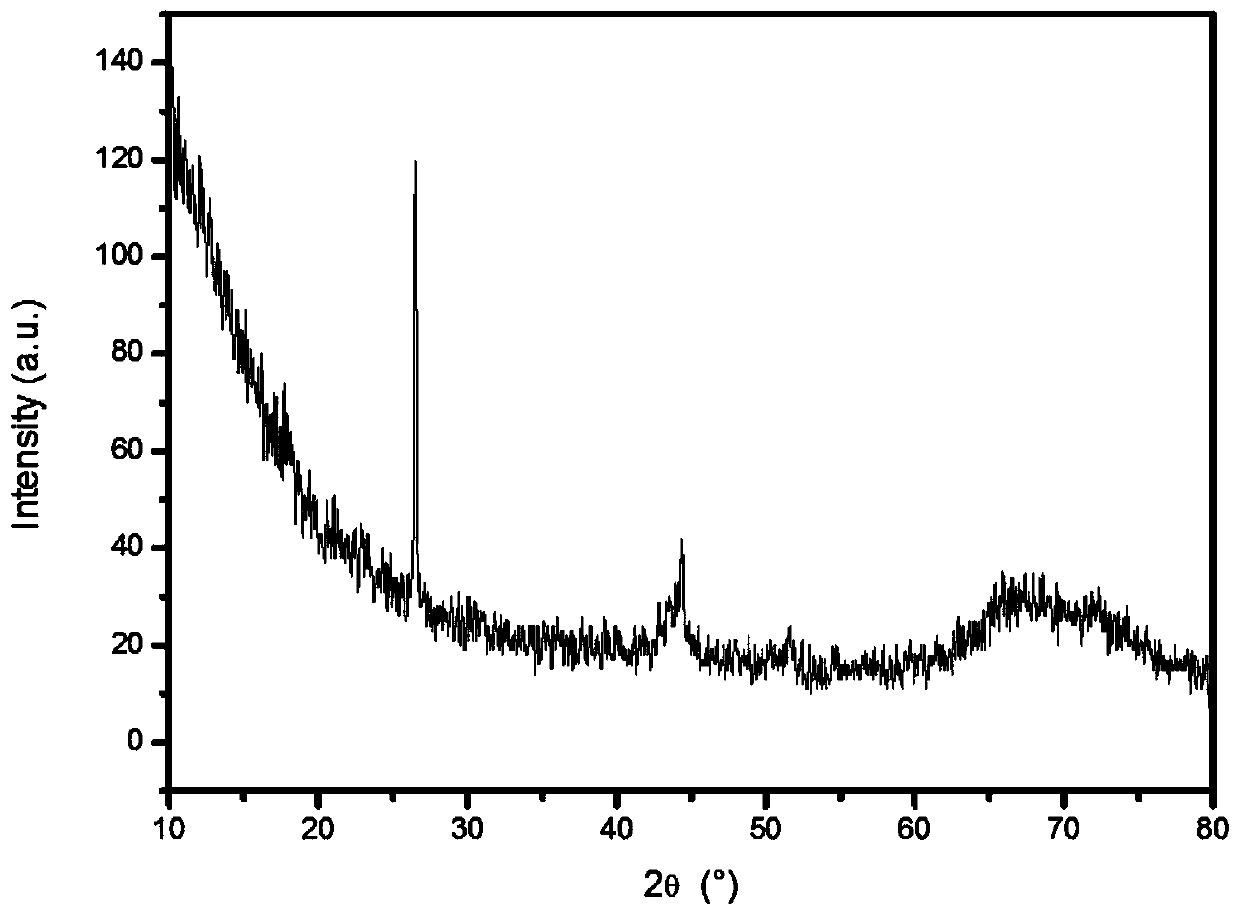

[0038] A method for preparing a graphene-like structure carbon electrode material using biomass rice husks as a raw material, comprising the following steps:

[0039] Step 1: drying the rice hulls at 60°C.

[0040] Step 2: Stir and mix the dried rice hulls in an aqueous solution of nickel nitrate evenly, soak them in it for 12 hours and then bake them at 60°C for 24 hours. At this time, there is no obvious moisture on the surface of the rice hulls; the mass of nickel nitrate is the mass of dried rice hulls 5%.

[0041] Step 3: Put the substance treated in Step 2 in a tube furnace, raise the temperature to 700° C. for 1 hour at a rate of 10° C. / min in a nitrogen atmosphere, carry out carbonization and catalysis, and obtain a preliminary carbonized product.

[0042]Step 4: soak and stir the preliminary carbonized product in Step 3 in 1 mol / L nitric acid solution for 24 hours, filter with suction, wash with water, and dry at 80° C. for 12 hours to obtain the carbonized product. ...

Embodiment 2

[0051] A method for preparing a graphene-like structure carbon electrode material using biomass rice husks as a raw material, comprising the following steps:

[0052] Step 1: drying the rice hulls at 70°C.

[0053] Step 2: Stir and mix the dried rice husks in an aqueous solution of nickel chloride evenly, soak them for 12 hours and then bake them at 55°C for 36 hours. At this time, there is no obvious moisture on the surface of the rice husks; 5% of shell mass.

[0054] Step 3: Put the substance treated in Step 2 in a tube furnace, raise the temperature to 650°C at a heating rate of 8°C / min in a nitrogen atmosphere and keep it for 1.5h for carbonization and catalysis to obtain a preliminary carbonized product.

[0055] Step 4: soak and stir the preliminary carbonized product in step 3 in 0.5 mol / L hydrochloric acid solution for 24 hours, suction filter, wash with water, and dry at 100° C. for 12 hours to obtain the carbonized product.

[0056] Step 5: Mix and stir the carbon...

Embodiment 3

[0060] A method for preparing a graphene-like structure carbon electrode material using biomass rice husks as a raw material, comprising the following steps:

[0061] Step 1: drying the rice husks at 80°C.

[0062] Step 2: Stir and mix the dried rice husks in an aqueous solution of nickel nitrate evenly, soak them in it for 12 hours and then bake them at 65°C for 24 hours. At this time, there is no obvious moisture on the surface of the rice husks; the mass of nickel nitrate is the mass of dried rice husks 5%.

[0063] Step 3: Put the substance treated in Step 2 in a tube furnace, raise the temperature to 750°C at a heating rate of 5°C / min in a nitrogen atmosphere and keep it for 1.5h for carbonization and catalysis to obtain a preliminary carbonized product.

[0064] Step 4: soak and stir the preliminary carbonized product in step 3 in 5 mol / L nitric acid solution for 24 hours, suction filter, wash with water, and dry at 120°C for 12 hours to obtain the carbonized product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com