Preparation method of water-permeable concrete

A technology of permeable concrete and preparation steps, which is applied in the field of permeable concrete preparation, can solve the problems of lower concrete compressive strength and affect the use range of concrete, and achieve the effect of good water permeability and rich pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

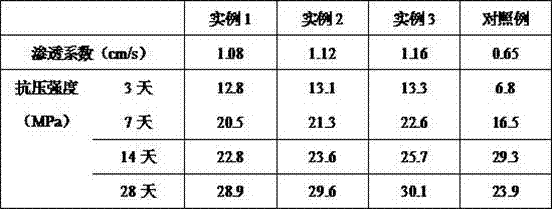

Examples

example 1

[0026]Weigh the elephant ear sponge and put it into a jet mill to pulverize and screen out the elephant ear sponge particles with a particle size of 5 mm, rinse the obtained elephant ear sponge particles with water for 30 minutes, and then put the washed elephant ear sponge particles into the fumigation furnace , preheated to 170°C, then heated the tetraethyl orthosilicate to boiling, and passed the tetraethyl orthosilicate vapor generated after boiling into the tube furnace, fumigated the washed elephant ears with tetraethyl orthosilicate vapor Sponge granule 5h, obtain pretreatment elephant ear sponge granule; Pretreatment elephant ear sponge granule and mass concentration are 3g / L dopamine solution by mass ratio after being mixed in 1:8 and put into the ultrasonic vibrator, at power is 300W, frequency Under the condition of 50kHz, ultrasonic vibration treatment for 2h, filtration, and separation to obtain the filter residue; according to the mass ratio of 1:5, the filter res...

example 2

[0028] Weigh the honeycomb cotton and put it into a jet mill to pulverize and screen out the honeycomb cotton particles with a particle size of 3 mm, rinse the obtained honeycomb cotton particles with water for 20 minutes, then put the washed honeycomb cotton particles into a fumigation furnace, and preheat to 160°C, then heat the tetraethyl orthosilicate to boiling, and pass the tetraethyl orthosilicate vapor generated after boiling into the tube furnace, fumigate and wash the honeycomb sponge particles with the tetraethyl orthosilicate vapor for 3 hours, and obtain Pretreated honeycomb cotton particles; mix pretreated honeycomb cotton particles with a mass concentration of 3g / L dopamine solution at a mass ratio of 1:8, put them into an ultrasonic oscillator, and ultrasonically oscillate at a power of 200W and a frequency of 40kHz Treat for 1 hour, filter, and separate to obtain the filter residue; mix the filter residue and the sodium silicate solution with a mass fraction of...

example 3

[0030] Weigh the silk floss and put it into a jet mill to pulverize and screen out the silk floss particles with a particle size of 4 mm, rinse the obtained silk floss particles with water for 25 minutes, then put the rinsed silk floss particles into a fumigation furnace, preheat to 165°C, and then Heating tetraethyl orthosilicate to boiling, and passing the tetraethyl orthosilicate vapor generated after boiling into a tube furnace, and using tetraethyl orthosilicate vapor to fumigate and wash the silk floss particles for 4 hours to obtain pretreated silk floss particles; Mix the pretreated silk floss granules and dopamine solution with a mass concentration of 3g / L at a mass ratio of 1:8, put them into an ultrasonic oscillator, conduct ultrasonic oscillation treatment for 2 hours at a power of 250W, and a frequency of 45kHz, filter, and separate to obtain filter residue; according to the mass ratio of 1:5, the filter residue and the sodium silicate solution with a mass fraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com