Carbon nanotube flexible conductive aerogel having water sensing function and preparation method thereof

A carbon nanotube, flexible and conductive technology, applied in the field of cellulose airgel polymer composite materials and its preparation, can solve the problems of electrical and mechanical properties, consumption of large carbon nanotubes, etc., and achieve simple operation, rich and easy raw materials The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

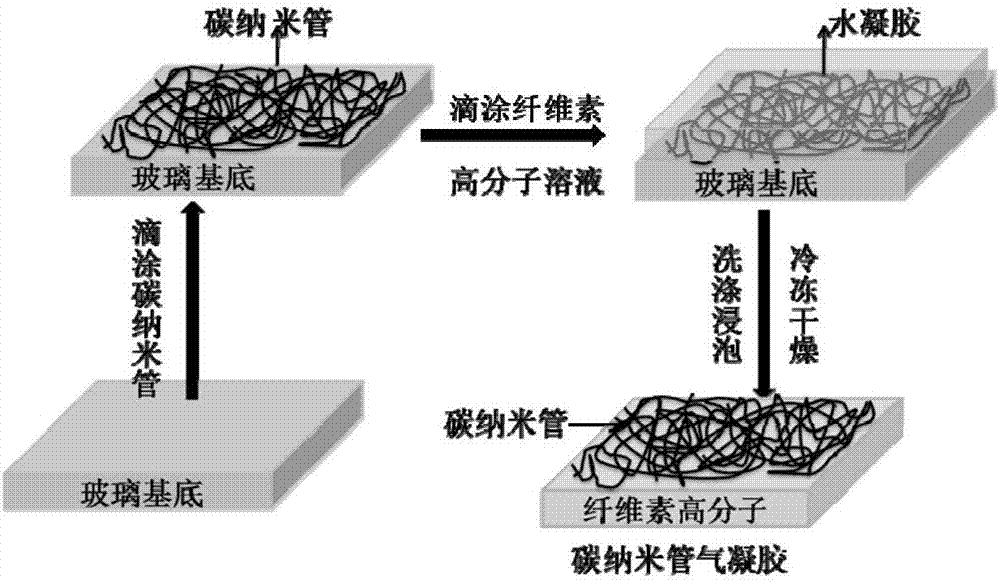

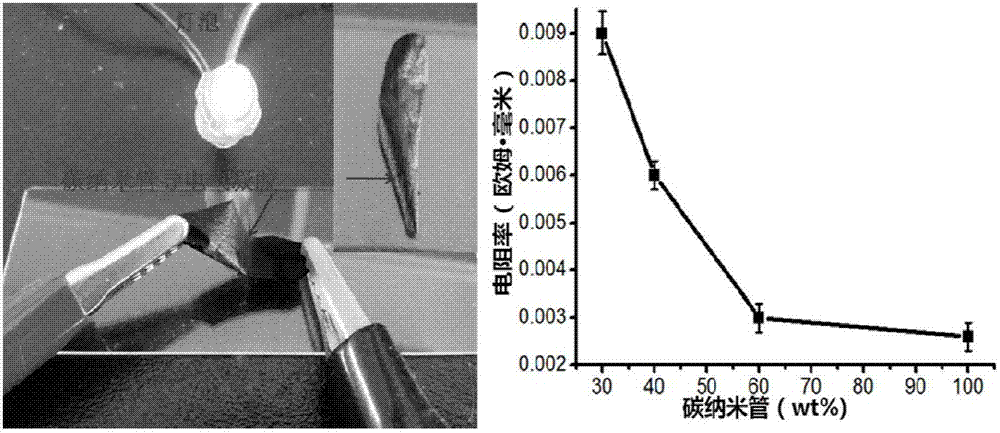

[0026] (1) Disperse the acidified carbon nanotubes into an ethanol solvent, then drop-coat the carbon nanotubes on the glass substrate, and finally obtain a carbon nanotube conductive layer with a mass of 9 mg.

[0027] (3) Heat the dried natural cellulose pulp at 160°C in a mixed solution of potassium permanganate and N,N dimethylacetamide, stir for 1 hour, and then filter with suction to obtain activated natural cellulose .

[0028] (4) heating the mixed solution of natural cellulose activated in step (2), N,N dimethylacetamide and lithium chloride at 100°C, the reaction time is 2 hours, and stirred at room temperature for 24 hours to obtain A cellulose polymer solution with a concentration of 10mg / ml.

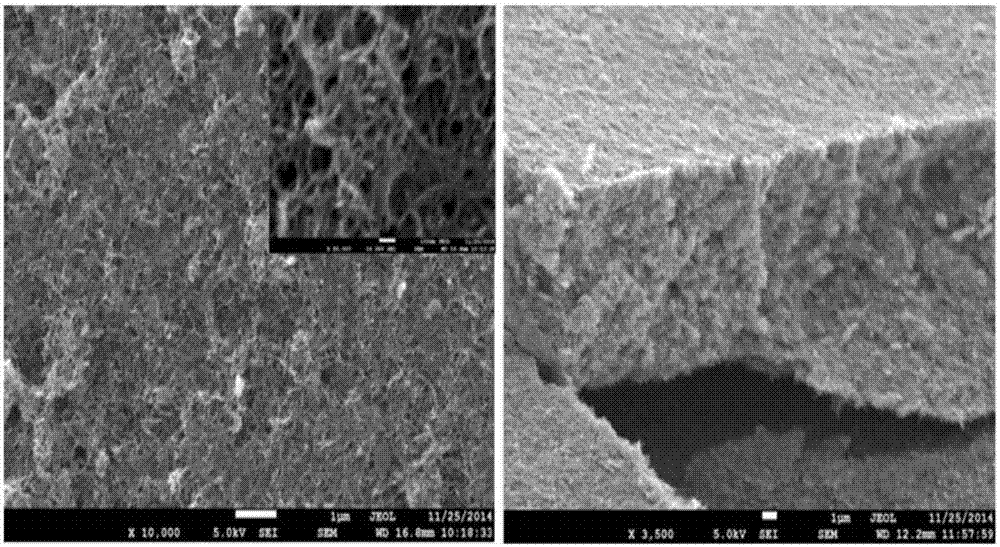

[0029] (5) 2.1ml of cellulose polymer solution is uniformly drip-coated on the carbon nanotube conductive layer of step (1), then the surface of the cellulose polymer solution is washed with ethanol solution, and then soaked in an aqueous solution for 24 hours to obtain a p...

Embodiment 2

[0033] (1) The acidified carbon nanotubes were dispersed into an ethanol solvent, and then the carbon nanotubes were drop-coated on the glass substrate, and the mass of the finally obtained carbon nanotube conductive layer was 12 mg.

[0034] (3) Heat the dried natural cellulose pulp at 160°C in a mixed solution of potassium permanganate and N,N dimethylacetamide, stir for 1 hour, and then filter with suction to obtain activated natural cellulose .

[0035] (4) heating the mixed solution of natural cellulose activated in step (2), N,N dimethylacetamide and lithium chloride at 100°C, the reaction time is 2 hours, and stirred at room temperature for 24 hours to obtain A cellulose polymer solution with a concentration of 5 mg / ml.

[0036] (5) 1.8ml of cellulose polymer solution is uniformly drip-coated on the carbon nanotube conductive layer of step (1), then the surface of the cellulose polymer solution is washed with ethanol solution, and then soaked in an aqueous solution for...

Embodiment 3

[0040] (1) The acidified carbon nanotubes were dispersed into ethanol solvent, and then the carbon nanotubes were drop-coated on the glass substrate, and the mass of the finally obtained carbon nanotube conductive layer was 18 mg.

[0041] (3) Heat the dried natural cellulose pulp at 160°C in a mixed solution of potassium permanganate and N,N dimethylacetamide, stir for 1 hour, and then filter with suction to obtain activated natural cellulose .

[0042](4) heating the mixed solution of natural cellulose activated in step (2), N,N dimethylacetamide and lithium chloride at 100°C, the reaction time is 2 hours, and stirred at room temperature for 24 hours to obtain A cellulose polymer solution with a concentration of 5 mg / ml.

[0043] (5) 1.2ml of cellulose polymer solution is uniformly drip-coated on the carbon nanotube conductive layer of step (1), then the surface of the cellulose polymer solution is washed with ethanol solution, and then soaked in an aqueous solution for 24 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com