A kind of aqueous UV polyurethane acrylate dispersion with self-initiating function and preparation method thereof

A polyurethane acrylate, self-initiating technology, applied in polyurea/polyurethane coatings, coatings, anti-corrosion coatings, etc., can solve the problems of adverse effects on product quality, slow curing rate, mixing and dispersion, etc., and achieve good storage stability and durability Good chemical properties and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

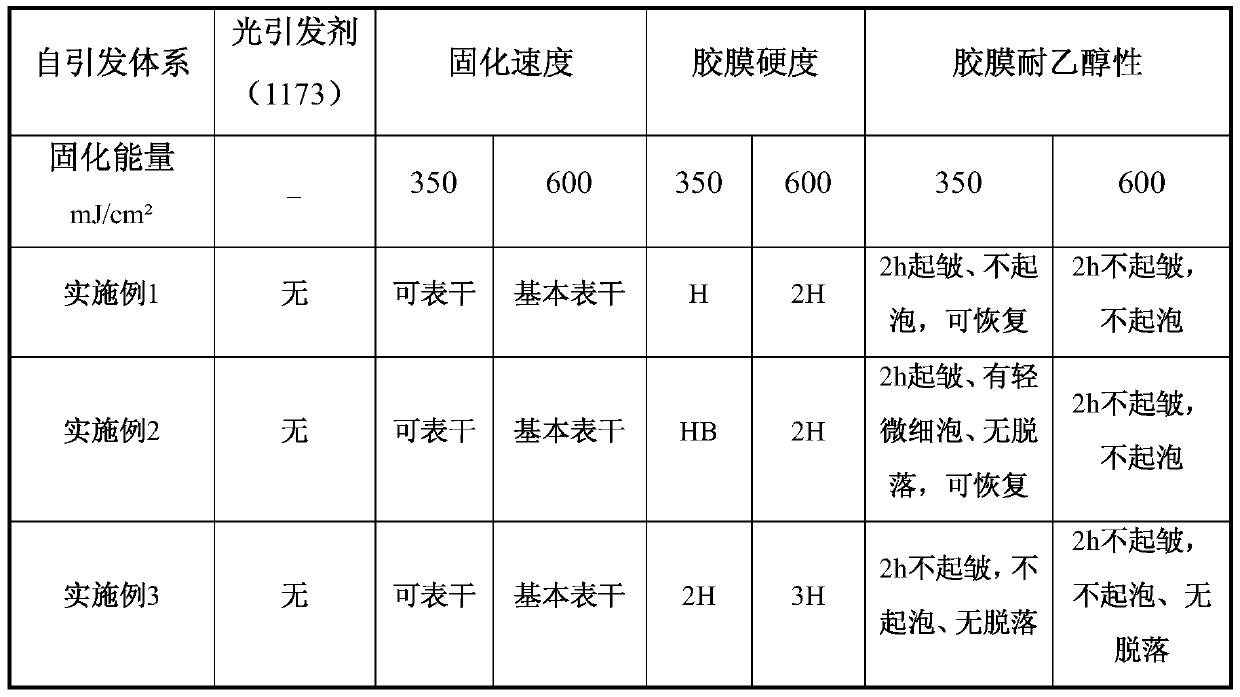

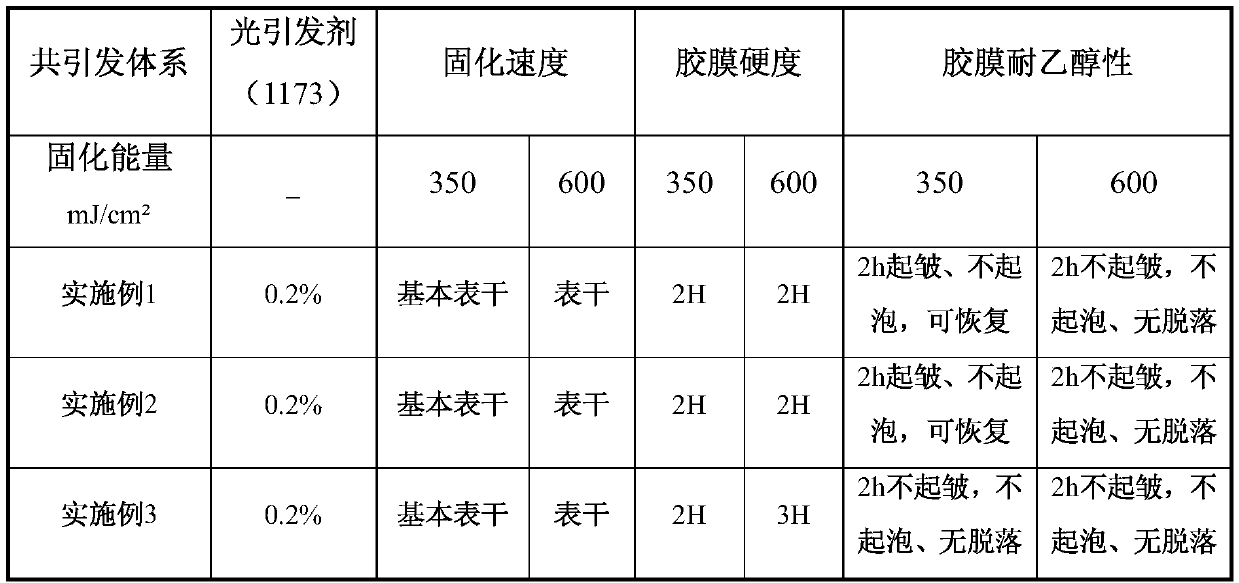

Examples

Embodiment 1

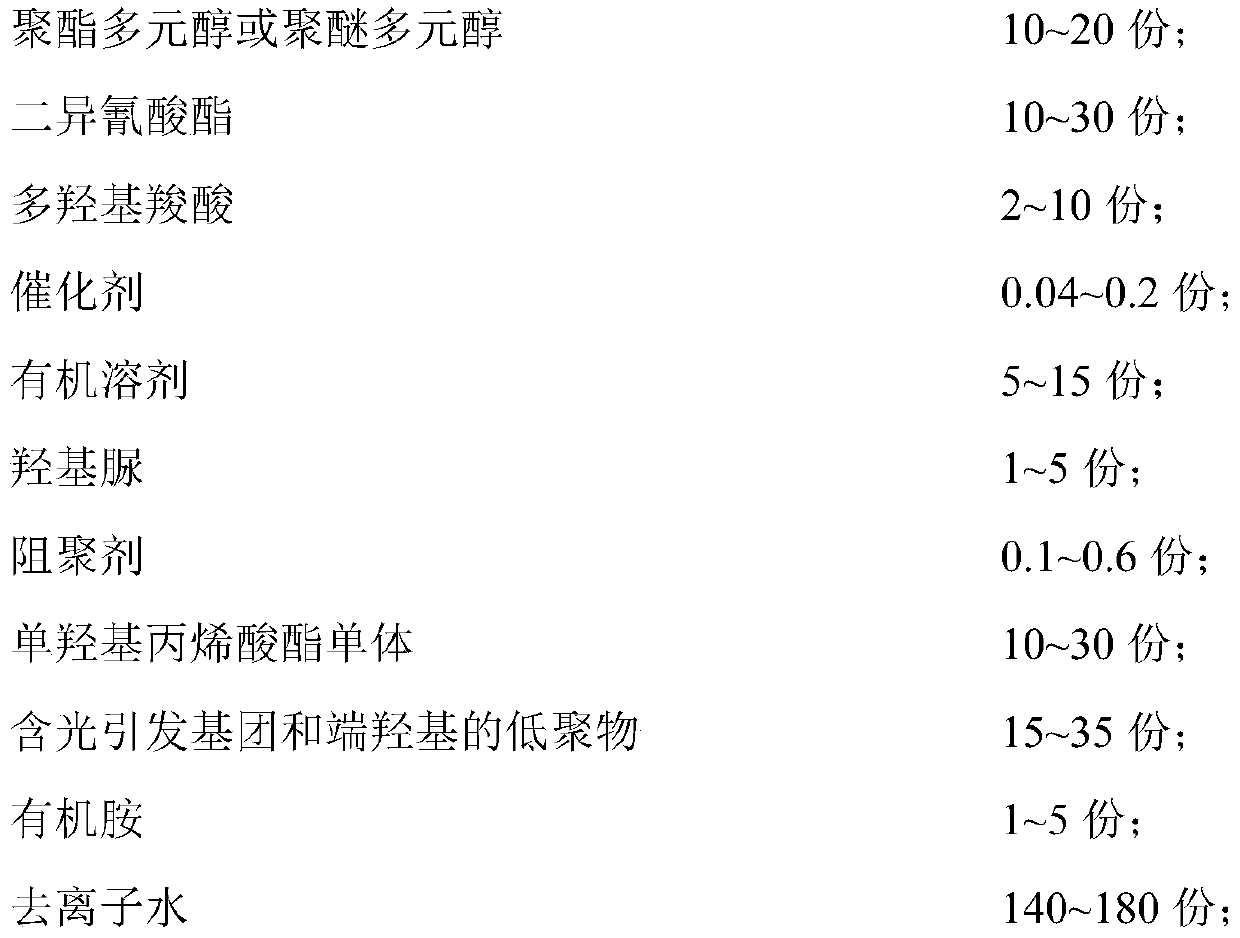

[0025] A water-based UV urethane acrylate dispersion with self-initiating function of the present invention and a preparation method thereof. The preparation method of this aqueous UV polyurethane acrylate dispersion comprises the following steps:

[0026] (1) Preparation of oligomers containing photoinitiating groups and terminal hydroxyl groups:

[0027] Add 24.6g of Darocurl 173 photoinitiator, 30g of acetone, and 0.08g of dibutyltin dilaurate into a single-necked flask, stir and dissolve at 60°C until it becomes a transparent liquid, and obtain a mixed solution of hydroxyl-containing photoinitiator, which is left to stand for use; Add 25.2g of 1,6-hexamethylene diisocyanate into the reaction vessel, raise the temperature to 65°C, add the mixed solution of hydroxyl-containing photoinitiator dropwise while stirring, control the dropping rate at 1.0 drops / second until all drops are completed, and raise the temperature to 70°C, Continue to react for 4.0h; when NCO% (the mass ...

Embodiment 2

[0032] A water-based UV urethane acrylate dispersion with self-initiating function of the present invention and a preparation method thereof. The preparation method of this aqueous UV polyurethane acrylate dispersion comprises the following steps:

[0033] (1) Preparation of oligomers containing photoinitiating groups and terminal hydroxyl groups:

[0034] Add 36.2g of Irgacure2959 photoinitiator, 35g of methyl ethyl ketone, and 0.15g of stannous octoate into a single-necked flask, stir and dissolve at 55°C to a transparent liquid, and obtain a mixed solution of hydroxyl-containing photoinitiator, which is left to stand for use; 36.5g Add isophorone diisocyanate into the reaction vessel, raise the temperature to 65°C, add the mixed solution of hydroxyl-containing photoinitiator dropwise while stirring, control the dropping rate at 1.0 drops / second until all drops are completed, raise the temperature to 75°C, and continue the reaction 3.0h; when the NCO% reaches the theoretica...

Embodiment 3

[0039] A water-based UV urethane acrylate dispersion with self-initiating function of the present invention and a preparation method thereof. The preparation method of this aqueous UV polyurethane acrylate dispersion comprises the following steps:

[0040] (1) Preparation of oligomers containing photoinitiating groups and terminal hydroxyl groups:

[0041] Add 45.4g of Irgacure184 photoinitiator, 45g of acetone, and 0.18g of dibutyltin dichloride into a single-necked flask, stir and dissolve at 50°C to a transparent liquid, and obtain a mixed solution of hydroxyl-containing photoinitiator, which is left to stand for use; Add 31.4g of dicyclohexylmethane diisocyanate into the reaction vessel, raise the temperature to 60°C, add the mixed solution of hydroxyl-containing photoinitiator dropwise while stirring, control the dropping rate at 1.0 drops / second until all drops are completed, and raise the temperature to 70°C , continue to react for 2.0h; when the NCO% reaches the theor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com