Semiconductor bonding technology based on palladium copper wire

A bonding process and semiconductor technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems of narrow welding process parameters, complicated process, high difficulty, etc., and achieve a wide range of bonding process parameters, Eliminate oxidation problems and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of semiconductor bonding process based on palladium copper wire that the present embodiment provides, it comprises:

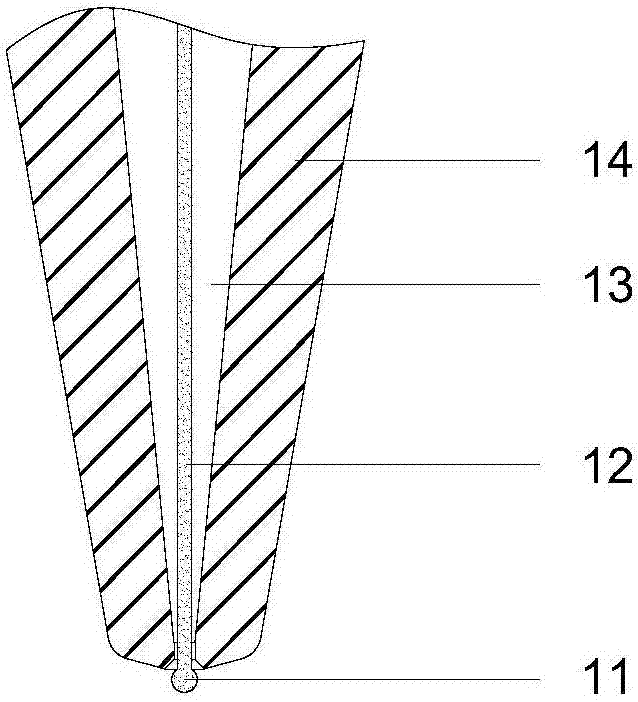

[0048] Step 1: Burn the ball, EFO (EFO, Electronic Flame Offs, the high-voltage electricity generated by the ignition box is transmitted to the tip of the ignition rod through the ignition cable, and the discharge between the exposed metal wire of the chopper forms a complete current loop .) Afterwards, burn-in balls 11 are formed (burn-in balls, FAB, Free Air Ball, that is, small balls formed by wire tail sintering after electronic ignition in the wire-bonding burn-in ball stage.) The size of burn-in balls 11 is 1.6-2.0 mil, where 11 is a pre-burned ball, 12 is a welding wire, 13 is a chopper cavity, and 14 is a chopper. See figure 1 .

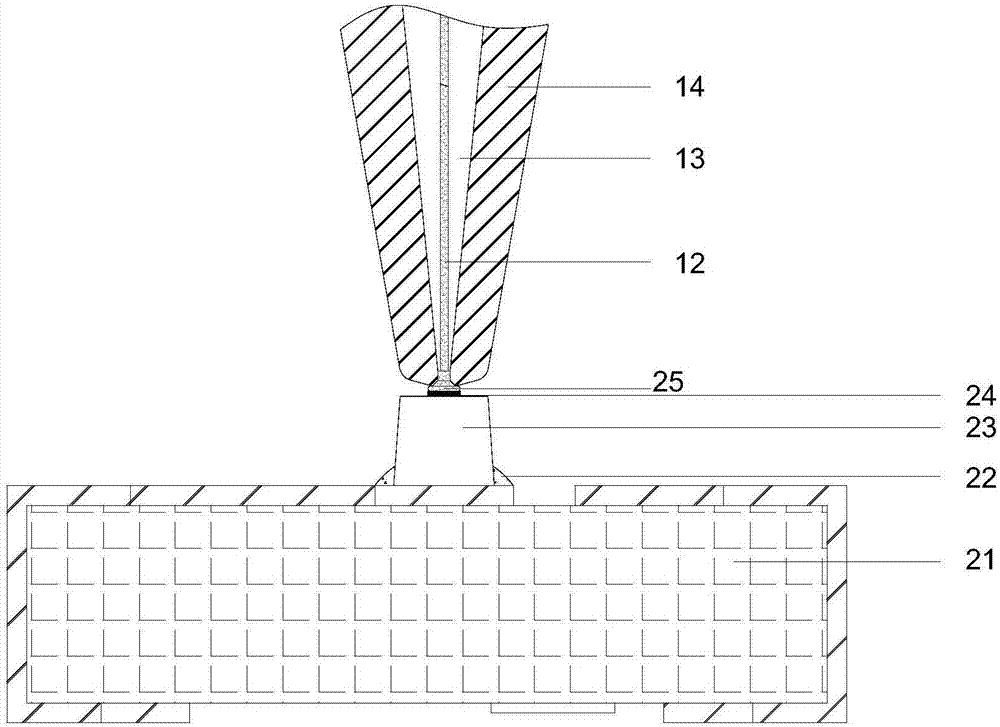

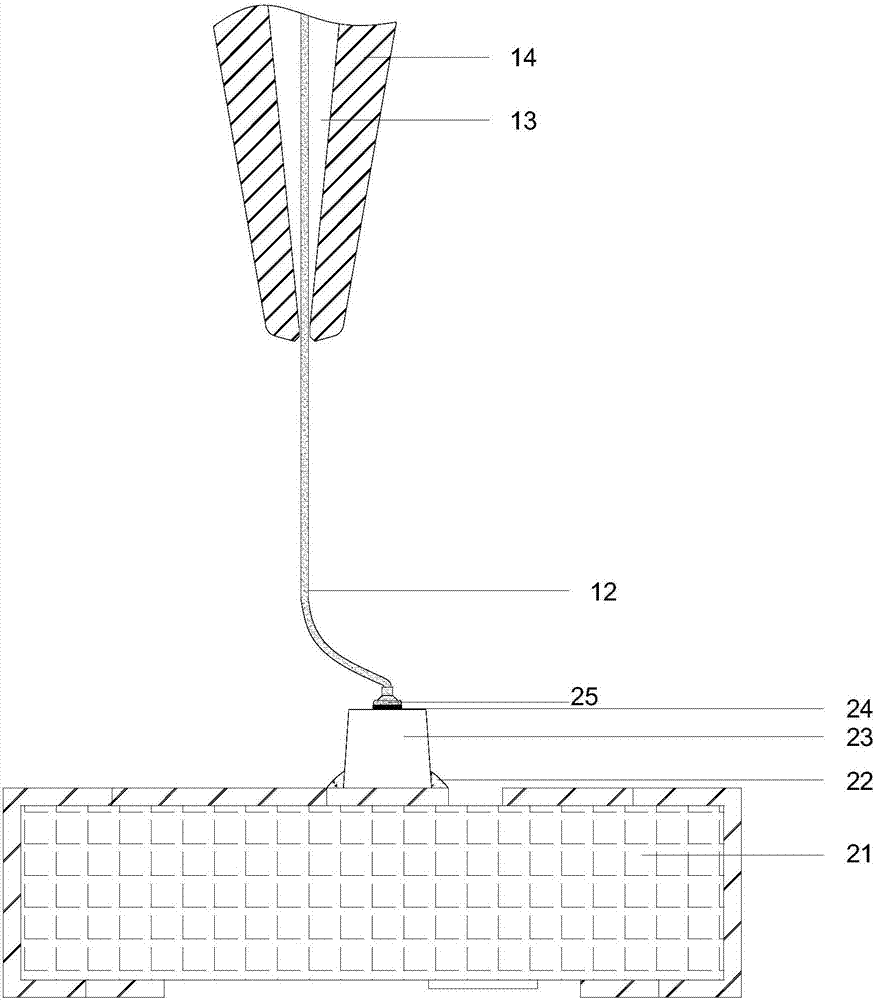

[0049]Step 2: 1 welding (welding of the first welding point), the chopper 14 moves to the position of the pad 24 of the 1 welding chip, and under the action of the set power, pressure and temperature, the 1 wel...

Embodiment 2

[0054] A kind of semiconductor bonding process based on palladium copper wire that the present embodiment provides, it comprises:

[0055] Step 1: First make pre-planted balls 4 on the board pad 311 (the second soldering functional area 311) of the PCB 31, and set the size of the pre-fired balls to 1.8-2.2 mil. In this process, a uniform and thin copper-nickel-gold-palladium-copper IMC (board pad 311 is copper, nickel, and gold) or copper-nickel-silver-palladium-copper IMC (board pad 311 is copper, copper, and gold) is formed in the second welding functional area 311. Nickel, silver three layers), see Figure 6 .

[0056] Step 2: Burn the ball, EFO (EFO, Electronic Flame Offs, the high-voltage electricity generated by the ignition box is transmitted to the tip of the ignition rod through the ignition cable, and the discharge between the exposed metal wire of the chopper forms a complete current loop .) Afterwards, burn-in balls 11 are formed (burn-in balls, FAB, Free Air Bal...

Embodiment 3

[0071] See Figure 11 .

[0072] A semiconductor bonding process based on palladium copper wire, comprising:

[0073] A. Move the chopper to the position of the chip pad, and use a bonding wire composed of a palladium-plated pure copper wire to make the solder ball of the first solder joint;

[0074] B. Pull the wire arc, the welding head drives the rivet to lift up, the welding wire is pulled to the set height, and then moves from the highest point to the second solder joint on the PCB board to complete the wiring of the welding wire;

[0075] C. Move the chopper to the position of the solder pad of the PCB board, and use the welding wire to weld the second solder joint;

[0076] Among them, when making the first solder joint and the second solder joint, use protective gas to fill the perimeter of the riving knife and the riving knife. The composition of the protective gas is: 95% to 99% nitrogen and 1% to 5% hydrogen, weight percentage.

[0077] 95-99% N 2 and 1 to 5% H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com