Preparation method of an eight-arm liquid crystal block copolymer composite electrolyte

A block copolymer and composite technology, which is applied in the field of electrolyte materials for lithium-ion batteries, can solve the problems of reduced ion mobility, etc., and achieve the effects of improving ion conductivity, stability, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

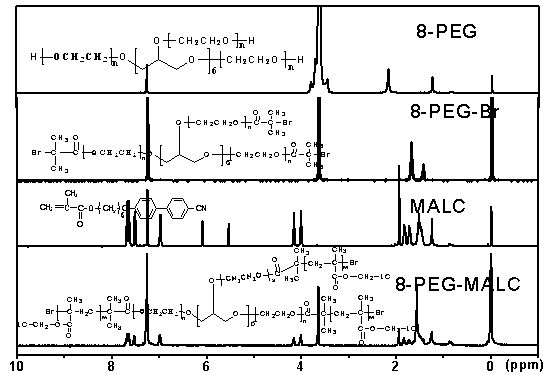

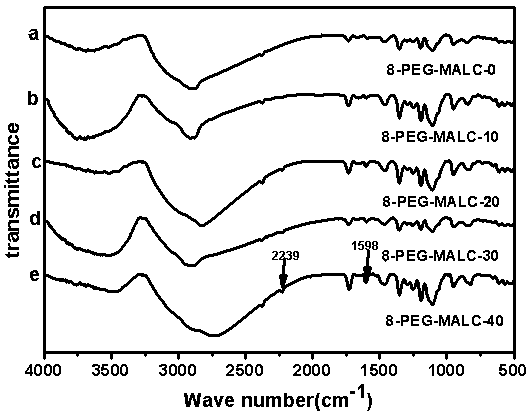

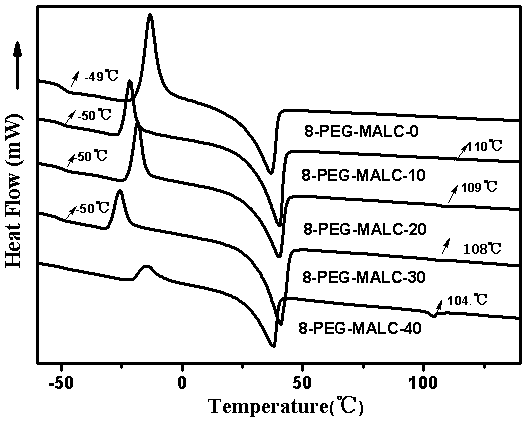

Method used

Image

Examples

Embodiment 1

[0036] The invention provides a method for preparing an eight-arm liquid crystal block copolymer composite electrolyte, comprising the following steps:

[0037] (1) Preparation of 4-cyano-4'-(6-hydroxyhexyloxy)biphenyl

[0038] Put 10mmol of p-cyanobiphenol and 30mmol of potassium carbonate in 100 mL of acetone to reflux, control the temperature at 65°C, reflux for 3 hours, then add 15 mmol of 6-bromo-n-hexanol and continue to reflux for 24 hours, first use 50 mL of chloroform The product was extracted 3 times, then washed 3 times with 50 mL deionized water, dried with 1 g anhydrous magnesium sulfate, filtered and recrystallized with 90 mL methanol to prepare 4-cyano-4'- (6-hydroxyhexyloxy)biphenyl;

[0039] (2) Preparation of 6-(4-cyano-4'-diphenoxy)hexyl methacrylate

[0040] Dissolve 10mmol of 4-cyano-4'-(6-hydroxyhexyloxy)biphenyl prepared in Step 1 in 100 mL of anhydrous tetrahydrofuran, stir for 3 h, and dissolve 11 mmol of anhydrous triethyl Amine and anhydrous tetrahy...

Embodiment 7

[0052] The invention provides a preparation method of an eight-arm liquid crystal block copolymer composite electrolyte, comprising the following steps:

[0053] (1) Preparation of 4-cyano-4'-(6-hydroxyhexyloxy)biphenyl

[0054] Put 8mmol of p-cyanobiphenol and 25mmol of potassium carbonate in 100 mL of acetone to reflux, control the temperature at 60°C, reflux for 4 hours, then add 12 mmol of 6-bromo-n-hexanol and continue to reflux for 22 hours, first use 50 mL of chloroform to The product was extracted 3 times, then washed 3 times with 50 mL of deionized water, dried with 1 g of anhydrous magnesium sulfate, filtered and recrystallized with 90 mL of methanol to prepare 4-cyano-4'-( 6-hydroxyhexyloxy) biphenyl;

[0055] (2) Preparation of 6-(4-cyano-4'-diphenoxy)hexyl methacrylate

[0056] Dissolve 10mmol of 4-cyano-4'-(6-hydroxyhexyloxy)biphenyl prepared in step 1 in 100 mL of anhydrous tetrahydrofuran, stir for 3 h, and dissolve 15 mmol of anhydrous triethyl Amine and an...

Embodiment 8

[0064] The invention provides a preparation method of an eight-arm liquid crystal block copolymer composite electrolyte, comprising the following steps:

[0065] (1) Preparation of 4-cyano-4'-(6-hydroxyhexyloxy)biphenyl

[0066] Put 15mmol of p-cyanobiphenol and 35mmol of potassium carbonate in 150 mL of acetone to reflux, control the temperature at 70°C, after reflux for 2 hours, then add 18 mmol of 6-bromo-n-hexanol and continue to reflux for 26 hours, first use 50 mL of chloroform The product was extracted 3 times, then washed 3 times with 50 mL deionized water, dried with 1 g anhydrous magnesium sulfate, filtered and recrystallized with 90 mL methanol to prepare 4-cyano-4'- (6-hydroxyhexyloxy)biphenyl;

[0067] (2) Preparation of 6-(4-cyano-4'-diphenoxy)hexyl methacrylate

[0068] Dissolve 12mmol of 4-cyano-4'-(6-hydroxyhexyloxy)diphenyl prepared in Step 1 in 120 mL of anhydrous tetrahydrofuran, stir for 3 h, and dissolve 15 mmol of anhydrous triethyl Amine and anhydrou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com