Front face release technique of suspended microstructure

A technology of microstructure and technology, applied in the direction of microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve the problems of insufficient release time, adhesion of suspended microstructure and substrate, etc., and achieve the effect of occupying a small chip area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

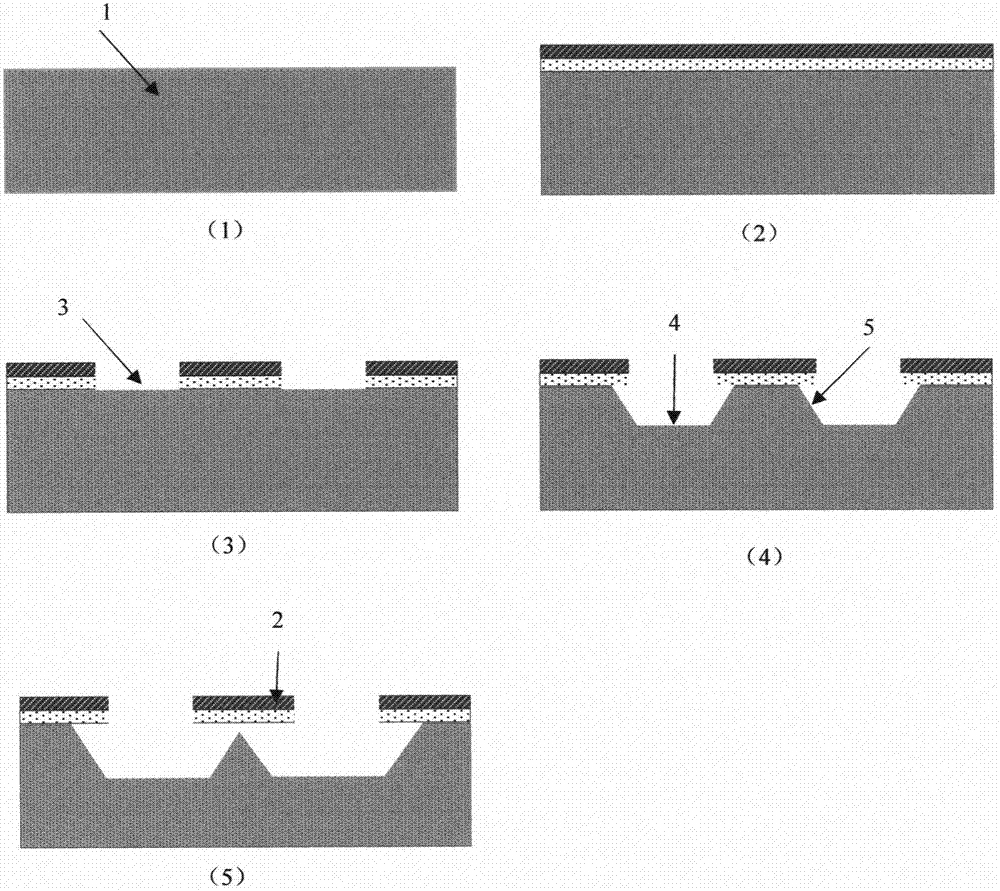

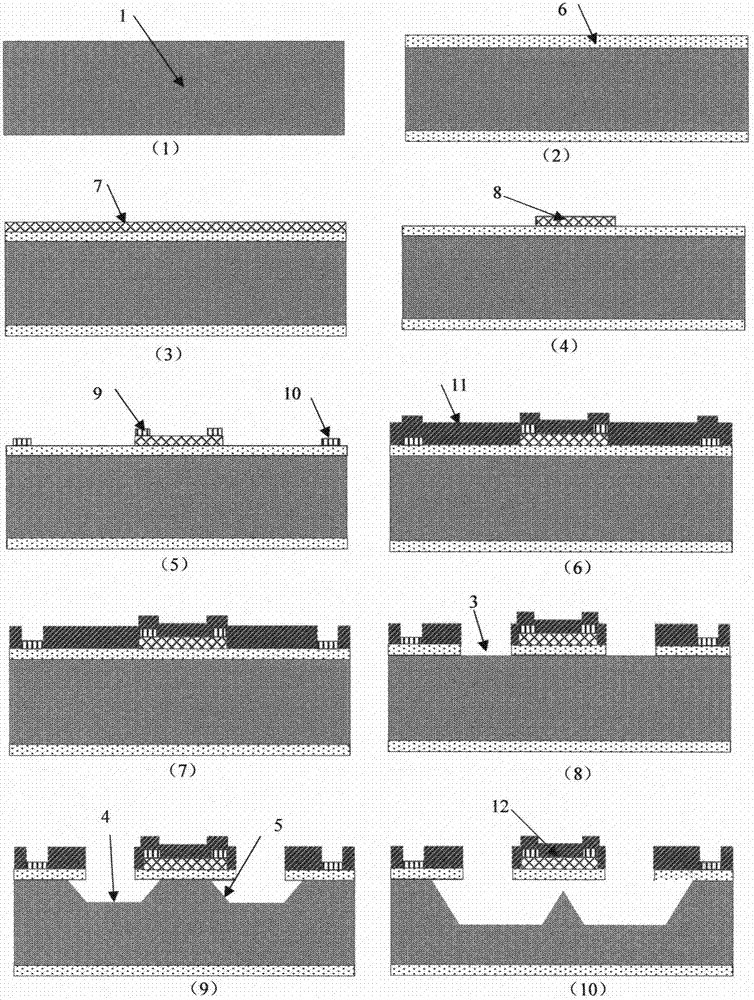

[0026] Embodiment: Utilize the suspended microstructure front release technology provided by the present invention to manufacture an electrothermal excitation / piezoresistive detection micro-bridge resonator, and its fabrication and front release process are as follows:

[0027] 1. The original silicon wafer is a heavily doped silicon wafer (1) with a (100) plane and a resistivity equal to 0.01Ω.cm. Standard cleaning, if attached figure 2 As shown in [1].

[0028] 2. Thermally oxidize and grow silicon dioxide film (6) at 1100°C, with a thickness of 0.6 μm, as attached figure 2 As shown in [2].

[0029] 3. Deposit polysilicon film (7) by low-pressure chemical vapor deposition method, with a thickness of 0.6 μm, as attached figure 2 Shown in [3].

[0030] 4. Ion-implanted boron, activated in a nitrogen environment at 950°C for 30 minutes, photolithographically etched the pattern of the polysilicon resistor (8), etched the polysilicon film (7) outside the resistance area, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com