Cadmium sulfide with adjustable hexagonal phase and cubic phase content, and preparation method and applications thereof

A cadmium sulfide, cubic phase technology, applied in cadmium sulfide, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve problems such as poor performance, achieve simple and easy process, and facilitate large-scale promotion , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing cadmium sulfide capable of regulating the content of hexagonal phase and cubic phase, the specific steps are as follows:

[0025] (1) Dissolve 0.2566g of sublimed sulfur in 25ml of diethylenetriamine, and stir at room temperature for 1h;

[0026] (2) Dissolve 0.2284g (half) cadmium chloride pentahydrate (so that the ratio of the amount of Cd to S is 1:8) in 25ml deionized water, and stir at room temperature for 20min;

[0027] (3) Mix the solution in step (1) and the solution in step (2), and stir at room temperature for 1 h;

[0028] (4) Transfer the mixed solution in step (3) to a polytetrafluoroethylene-lined stainless steel reaction kettle, and heat at 80° C. for 48 hours in a drying oven;

[0029] (5) The heated product was naturally cooled to room temperature, then centrifuged and washed with deionized water and absolute ethanol, and dried at 60° C. for 12 hours.

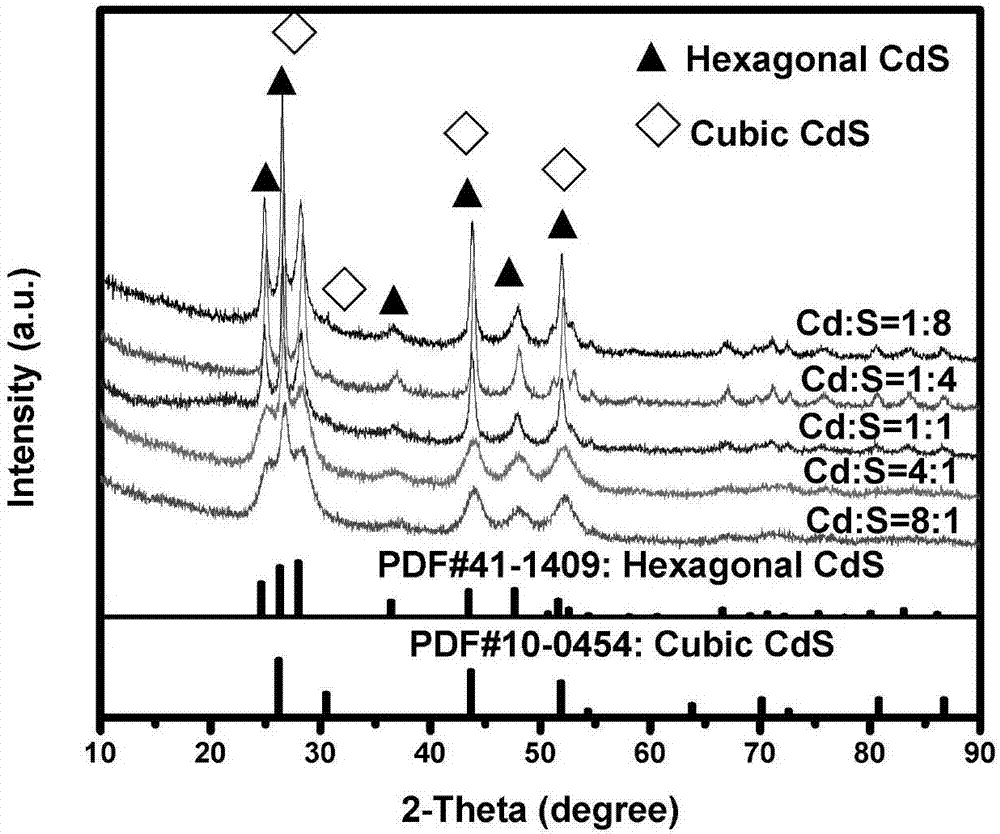

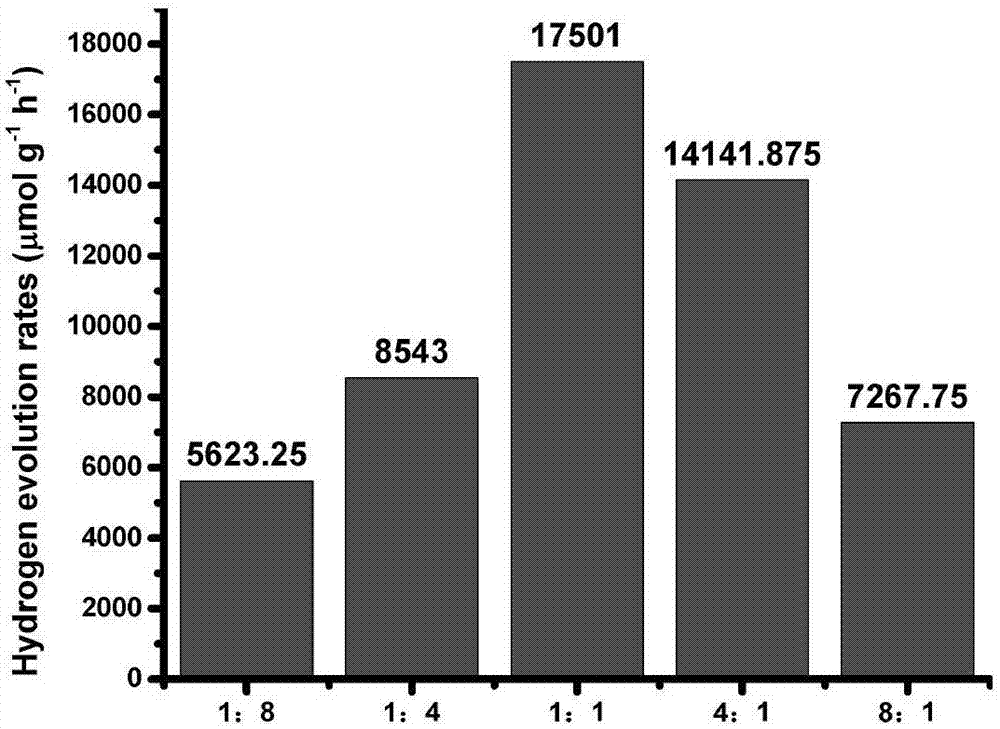

[0030] The hexagonal phase content in the cadmium sulfide prepared in this ...

Embodiment 2

[0032] The preparation method of this example is the same as that of Example 1, except that the mass of (semi) cadmium chloride pentahydrate in step (2) is changed to 0.4568g, so that the ratio of the amount of Cd to S is 1:4.

[0033] The hexagonal phase content in the cadmium sulfide prepared in this example is 68%, and the cubic phase content is 32%. The photocatalytic hydrogen production rate of cadmium sulfide under visible light (λ≥400nm) is 8543 μmol g -1 h -1 .

Embodiment 3

[0035] The preparation method of this example is the same as that of Example 1, except that the mass of (semi) cadmium chloride pentahydrate in step (2) is changed to 1.8273g, so that the ratio of the amount of Cd to S is 1:1.

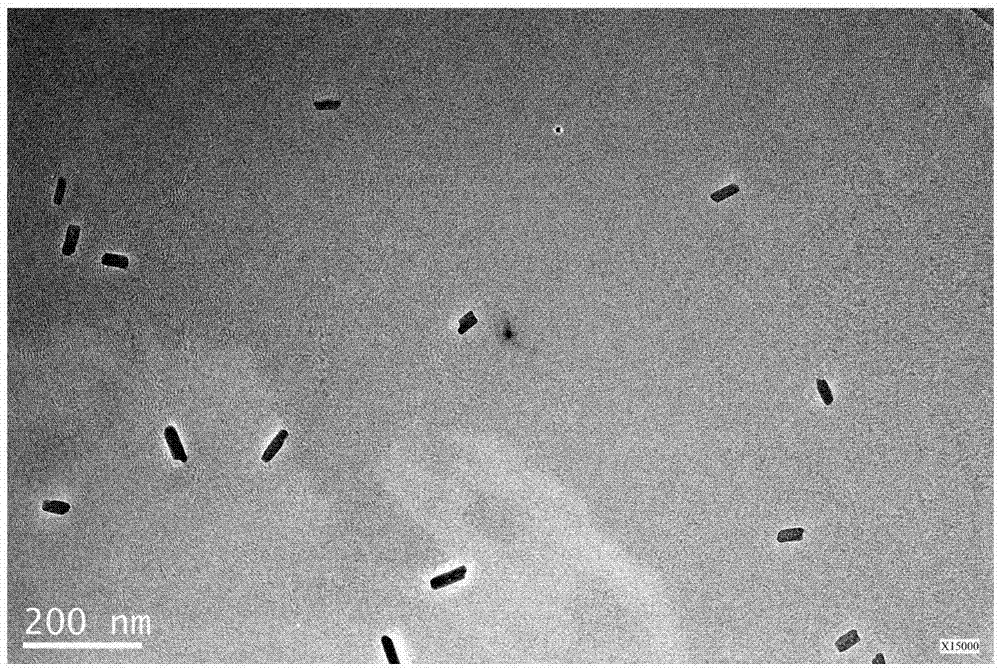

[0036] The morphology of the cadmium sulfide prepared in this embodiment is as follows: figure 2 As shown, CdS exhibits a sheet-like structure. The hexagonal phase content in CdS is 60.3%, and the cubic phase content is 39.7%. The photocatalytic hydrogen production rate of cadmium sulfide under visible light (λ≥400nm) is 17501 μmol g -1 h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com