Method of utilizing organic waste produced by fruit trees and vegetables to prepare organic fertilizer

A technology of organic waste and organic fertilizer, applied in the preparation of organic fertilizer, organic fertilizer, biological organic part treatment and other directions, can solve the problems of inability to return to the field, high production cost, and many returned materials, etc., to improve adsorption and ventilation. Function, shorten the fermentation cycle, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

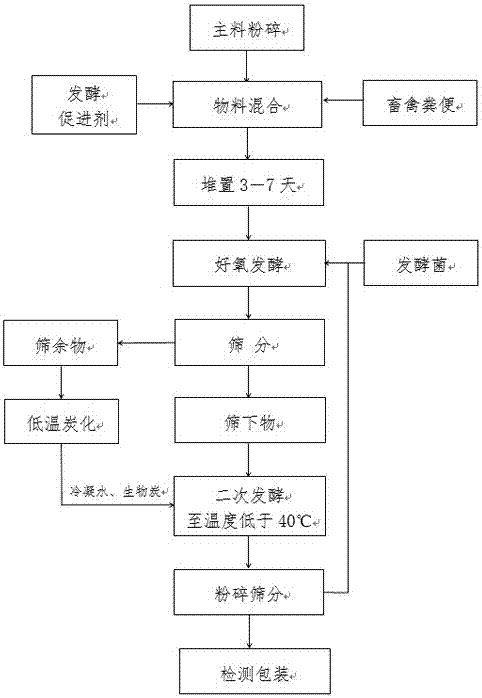

[0020] A method for preparing organic fertilizer from organic waste produced by vegetables, comprising the following steps:

[0021] a. Material mixing: Cut 1000Kg of vegetable straw waste from plastic and stone debris into 20 cm below with a hay cutter, pour it into the mixing tank, add 300Kg of cow and sheep manure, 100 kg of phosphate rock powder, wheat rice 50 kg of stone powder, stir evenly, adjust the water content to 58%, C / N = 25:1, pile up for 3 days;

[0022] b. Aerobic fermentation: stack the heat-generating mixed materials that have been stacked for 3 days in the fermentation tank and use a trough-type turning machine for turning and throwing treatment. When the temperature rises to 60°C, turn the pile and control the temperature at 62°C. The oxygen fermentation cycle is 5 days;

[0023] c. Secondary fermentation: After aerobic fermentation, use a sieve to sieve. The unfermented cellulose lignin on the sieve enters the carbonization furnace for anaerobic carboniza...

Embodiment 2

[0027] A kind of method that utilizes the organic waste that fruit tree produces to prepare organic fertilizer, comprises the following steps:

[0028] a. Material mixing: Use a sawdust grinder to grind 1000Kg of fruit tree pruning waste from plastic and stone debris into a size below 5 cm, pour it into a mixing tank, add 350Kg of cattle and sheep manure, 150 kg of phosphate rock powder, and stir Evenly, adjust the water content to 53%, C / N = 28:1, stack for 4 days;

[0029] b. Aerobic fermentation: Mix and stack the heat-generating mixed materials that have been piled up for 4 days in the fermentation tank, use a tank-type turning machine to turn over the mixed materials in the fermentation tank, and start turning when the temperature rises to 62°C Heap, control temperature at 65°C, aerobic fermentation cycle 6 days;

[0030] c. Secondary fermentation: After aerobic fermentation, sieve with a sieve, and the unfermented cellulose lignin on the sieve enters the carbonization f...

Embodiment 3

[0034] A method for preparing organic fertilizer from organic waste produced by fruit trees and vegetables, comprising the following steps:

[0035] a. Material mixing: Cut 500Kg of vegetable straw waste from plastic and stone debris into less than 20cm with a hay cutter, and crush 500Kg of fruit tree pruning waste into less than 5cm with a sawdust grinder, pour it into the mixture and stir In the tank, add 350Kg of cattle and sheep manure, 150 kg of phosphate rock powder, stir evenly, adjust the water content to 60%, C / N = 30:1, and pile up for 5 days;

[0036] b. Aerobic fermentation: stack the heated mixed materials that have been piled up for 5 days in the fermentation tank, and use the trough-type turning machine to turn over the mixed materials in the fermentation tank, and start turning when the temperature rises to 65°C , the temperature is controlled at 70°C, and the aerobic fermentation cycle is 5 days;

[0037] c. Secondary fermentation: After aerobic fermentation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com