Modification method of nanometer white carbon black

A nano-silica and modification technology, which is applied in the field of preparation of high-dispersion synthetic rubber filler nano-silica modification, can solve the problems of complicated operation, high production cost, poor dispersion stability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of monomer pre-emulsion: put 100 parts of styrene, 2.0 parts of sodium dodecylbenzenesulfonate, 200 parts of deionized water, 1.0 parts of sodium hydroxide, and 0.01 parts of potassium persulfate into the reactor , when the temperature was raised to 50°C, the reaction was stirred for 30 minutes to prepare styrene pre-emulsion a.

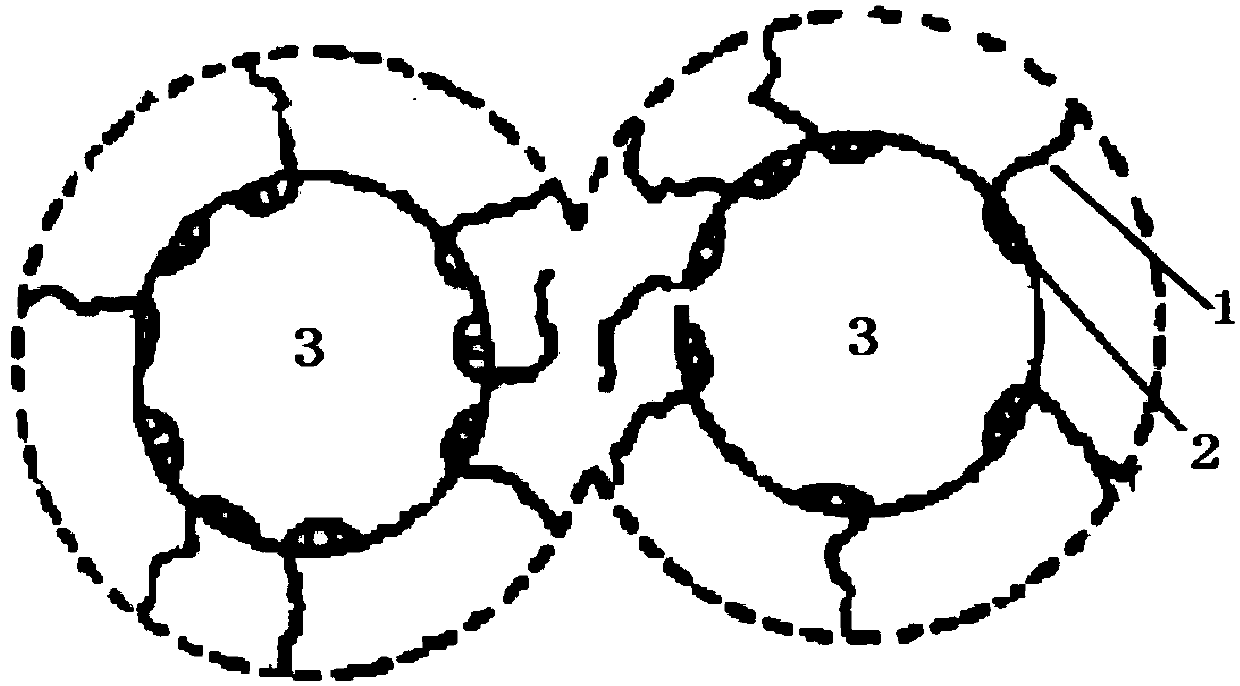

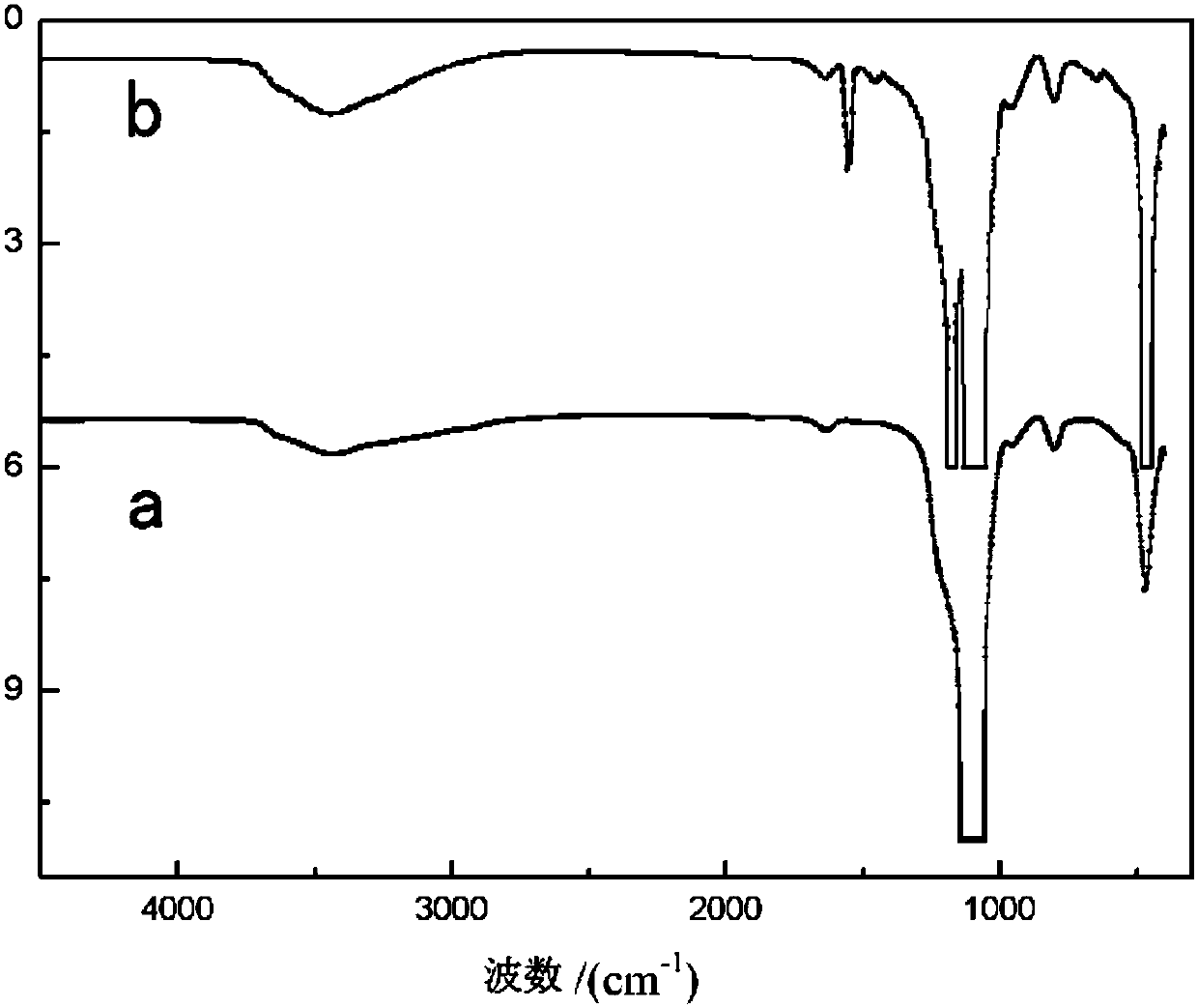

[0037] (2) Preparation of modified nano-silica: 100 parts of nano-silica (40nm), 1.0 part of acrylic acid (AA), 300 parts of deionized water, and 1.0 part of sodium hydroxide were added to the polymerization tank and stirred for 20 minutes; Then add 1.0 parts of sodium dodecylbenzenesulfonate and 1.5 parts of styrene pre-emulsion a, stir and heat up to 65 ° C, and then stir and mix for 20 minutes to generate the seeds of the composite emulsion centered on nano-silica powder; then Add 20 parts of styrene pre-emulsion a and 0.05 part of potassium persulfate, react for 3.0 hours, finally add 0.1 part of diethylhydroxylamine, wash,...

Embodiment 2

[0039] (1) Preparation of monomer pre-emulsion: with embodiment 1.

[0040] (2) Preparation of modified nano-silica: 100 parts of nano-silica (40nm), 2.2 parts of acrylic acid (AA), 350 parts of deionized water, and 2.0 parts of sodium hydroxide were added to the polymerization kettle and stirred for 20 minutes; Then add 2.5 parts of sodium dodecylbenzenesulfonate and 2.0 parts of styrene pre-emulsion a, stir and heat up to 65 ° C, and then stir and mix for 25 minutes to generate the seeds of the composite emulsion centered on nano-silica powder; then Add 25 parts of styrene pre-emulsion a and 0.09 part of potassium persulfate, react for 4.0 hours, finally add 0.2 parts of diethylhydroxylamine, wash, dehydrate, dry and grind to obtain modified nano-silica. Sampling and analysis: standard samples were made, and the tested properties are shown in Table 1.

Embodiment 3

[0042] (1) Preparation of monomer pre-emulsion: put 100 parts of styrene, 5 parts of sodium dodecylbenzenesulfonate, 240 parts of deionized water, 1.5 parts of sodium hydroxide, and 0.05 parts of potassium persulfate into the reactor , when the temperature was raised to 55°C, the reaction was stirred for 40 minutes to prepare styrene pre-emulsion b.

[0043] (2) Preparation of modified nano-silica: 100 parts of nano-silica (40nm), 2.5 parts of acrylic acid (AA), 370 parts of deionized water, and 2.5 parts of sodium hydroxide were added to the polymerization tank and stirred for 25 minutes; Then add 3 parts of sodium dodecylbenzenesulfonate and 2.5 parts of styrene pre-emulsion b, stir and heat up to 65 ° C, and then stir and mix for 25 minutes to generate the seeds of the composite emulsion centered on nano-silica powder; then Add 30 parts of styrene pre-emulsion b and 0.12 parts of potassium persulfate, react for 4.0 hours, finally add 0.25 parts of diethylhydroxylamine, wash...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com