Preparation method of modified graphene supported precious metal oxide anode

A noble metal oxide and oxide technology, applied in the field of electrochemistry, can solve the problems such as the inability to give full play to the excellent characteristics of high surface area, restrict the anode performance, high temperature ablation and decomposition of graphene, etc., and achieve the improvement of anode performance and electrocatalytic activity. and the effect of improved stability and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of described novel anode is:

[0041] The solution containing the modified graphene-loaded noble metal oxide was transferred to the electrolytic cell, the titanium substrate after degreasing and oxalic acid etching was used as the cathode, and the platinum sheet was used as the anode. cm 2 ~15mA / cm 2 , the electrodeposition time is 10min to 60min, and finally a modified graphene-enhanced metal oxide anode is obtained on the surface of the titanium substrate, and the metal oxide loading reaches 10g / m 2 ~15g / m 2 .

Embodiment 1

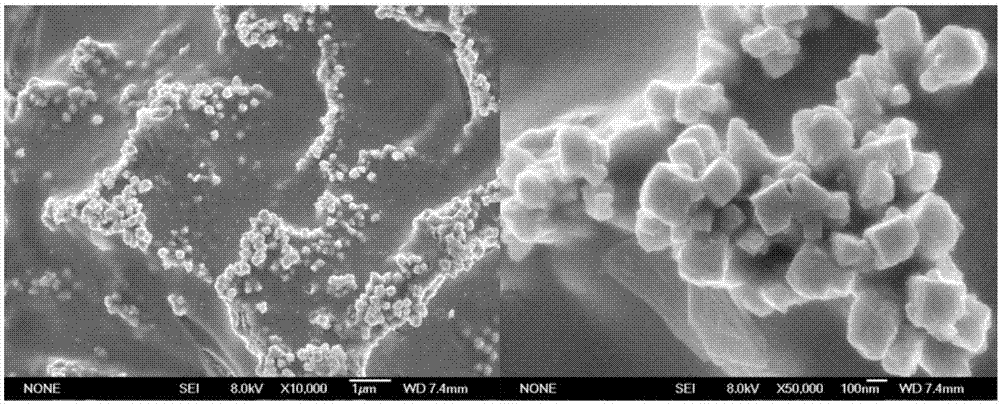

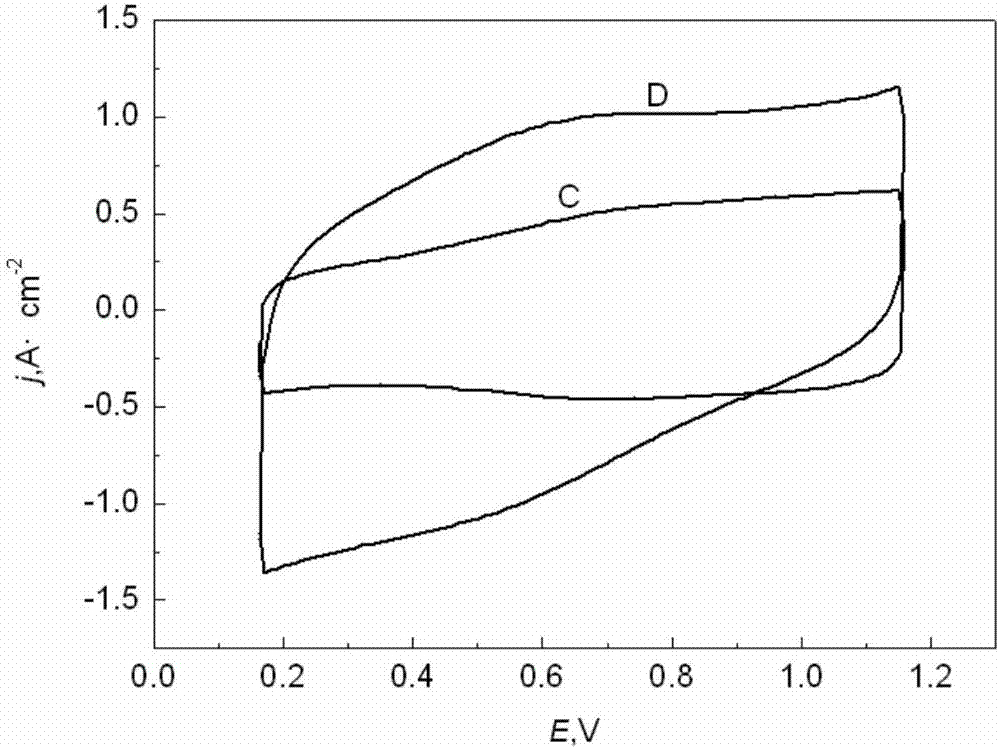

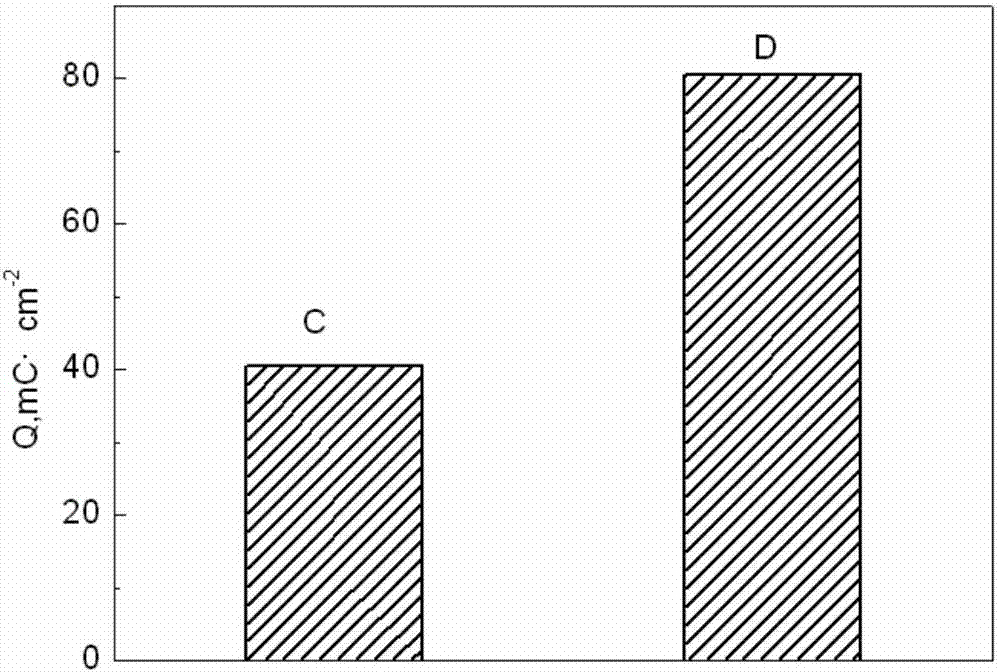

[0043] Example 1 Modified graphene loaded noble metal oxide anode

[0044] The first step, substrate pretreatment: use a TA2 industrial pure titanium plate with a plate shape of 140mm×110mm×3mm as the electrode substrate, first use corundum with a particle size of 120μm to sandblast the titanium plate, and rinse with distilled water to remove residual sand and metal chips; Then put the titanium plate into acetone for degreasing, finally put the degreasing titanium plate into 10% (mass fraction) oxalic acid solution, keep it in boiling state for 2h, take it out and rinse it with deionized water. Dry the above-mentioned treated titanium plates and put them in absolute ethanol for later use.

[0045] The second step, graphene modification, adopts commercially available graphene as the raw material, the single-layer rate is 80%, and the thickness is 0.8nm; the plasma pretreatment method is adopted, and the plasma treatment time is 120s under nitrogen atmosphere, and the flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com