A kind of high-strength high-modulus PVA fiber and its preparation method and application

A fiber and application technology, applied in the field of PVA fiber and its preparation, to achieve the effects of short gel breaking time, good sand suspension effect and little formation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

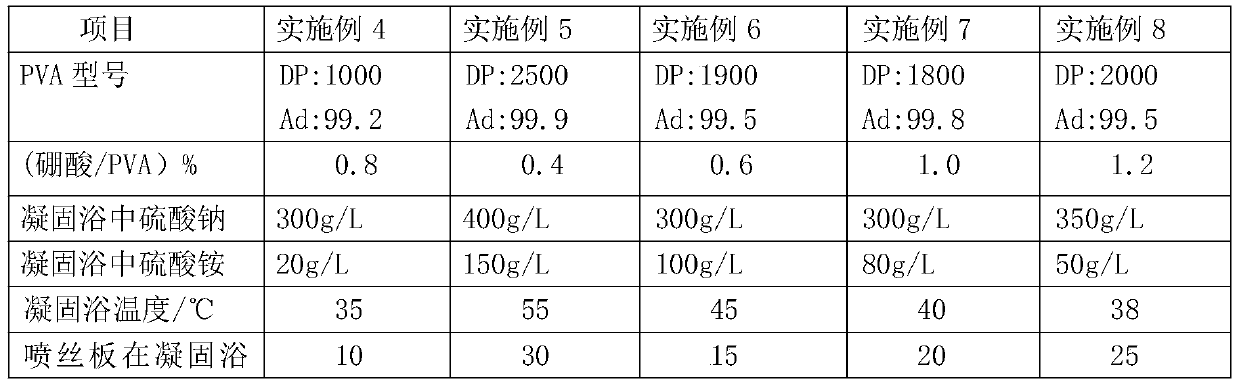

[0046] Embodiment 1: adopt the following steps to prepare high-strength and high-modulus PVA fibers:

[0047] (1) Preparation of spinning stock solution: the degree of polymerization is 1700, the degree of alcoholysis is 99.5 (mol)% PVA and boric acid, titanium dioxide are dispersed in water and made into spinning stock solution, wherein the mass concentration of PVA in the stock solution is 16% , the addition of boric acid is 1.2% of the mass of PVA, the addition of titanium dioxide is 0.25% of the mass of PVA, the stock solution is heated to 100°C, and the pressure is maintained at 0.10MPa, dissolved for 8 hours, and then it enters the spinning process after standing for 3 hours under normal pressure for defoaming process.

[0048] (2) Spinning: The PVA stock solution is sent to the spinning assembly by a metering pump, and the PVA stock solution is sprayed into the coagulation bath from the small hole of the spinneret. The composition of the coagulation bath is sodium sulf...

Embodiment 2

[0051] Embodiment 2: adopt the following steps to prepare high-strength and high-modulus PVA fibers:

[0052] (1) Preparation of spinning stock solution: the degree of polymerization is 2400, the degree of alcoholysis is 99.8 (mol)% PVA and boric acid, titanium dioxide are dispersed in water and made into spinning stock solution, wherein the mass concentration of PVA in the stock solution is 14% , the amount of boric acid added is 1.8% of the mass of PVA, the amount of added titanium dioxide is 0.4% of the mass of PVA, the stock solution is heated to 105°C, and the pressure is maintained at 0.08MPa, dissolved for 10 hours and left to stand under normal pressure for 6 hours after defoaming, then enter the spinning process .

[0053] (2) Spinning: The PVA stock solution is sent to the spinning assembly by a metering pump, and the PVA stock solution is sprayed into the coagulation bath from the small hole of the spinneret. The composition of the coagulation bath is sodium sulfat...

Embodiment 3

[0056] Embodiment 3: adopt the following steps to prepare high-strength and high-modulus PVA fibers:

[0057] (1) Preparation of spinning stock solution: the degree of polymerization is 2000, the degree of alcoholysis is 99.9 (mol)% PVA and boric acid, titanium dioxide are dispersed in water and made into spinning stock solution, wherein the mass concentration of PVA in the stock solution is 13% , the addition of boric acid is 1.0% of the mass of PVA, the addition of titanium dioxide is 3.0% of the mass of PVA, the stock solution is heated to 100°C, and the pressure is maintained at 0.06MPa. After dissolving for 9 hours, it is left to stand under normal pressure for 5 hours of defoaming, and then it enters spinning process.

[0058] (2) Spinning: The PVA stock solution is sent to the spinning assembly by a metering pump, and the PVA stock solution is sprayed into the coagulation bath from the small hole of the spinneret. The composition of the coagulation bath is sodium sulfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com